The Versatility of the AS/RS: Beyond the Ordinary

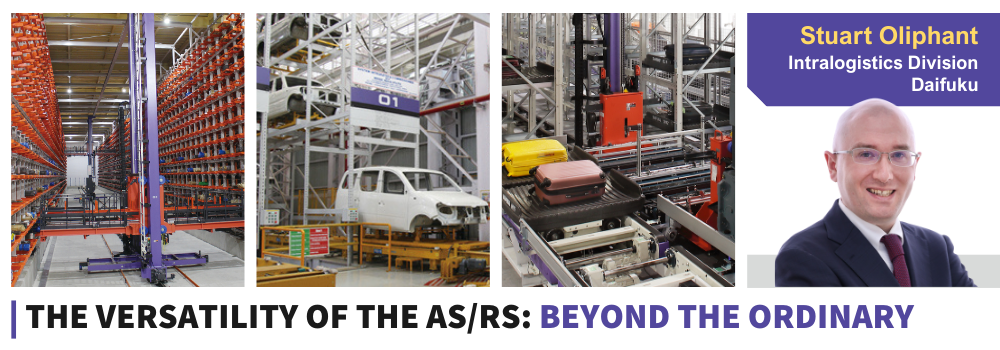

When you think about the kinds of items stored in an Automated Storage and Retrieval System (AS/RS), what comes to mind? A distribution center filled with cases? A warehouse storing pallets ready for shipment? Or perhaps a factory storing raw materials and finished goods. While these are common applications, the versatility of the AS/RS extends far beyond these typical uses.

An AS/RS can automate the storage of a diverse range of objects—varying in shape, size, and even cultural significance—far beyond what we might traditionally associate with automation.

Let’s explore some of the surprising and innovative ways these systems are being used.

Vehicle Bodies

In the automotive industry, the AS/RS can be used to store and manage work-in-process (WIP) vehicle bodies and even large vehicle parts. The AS/RS effectively acts as a buffer between two processes, ensuring that the large, heavy vehicle bodies are handled safely and efficiently, reducing the risk of damage and improving workflow in manufacturing plants. Furthermore, the AS/RS facilitates sequenced retrieval so that vehicle bodies and other large parts are retrieved in alignment with a site’s assembly order.

Read More

Case Study: Mahindra & Mahindra

Insights: Revving up Efficiency in Automotive Spare Parts Centers

Vertical Farming Trays

A more innovative application of the AS/RS is in vertical farming. By automating the storage and retrieval of plant trays, an AS/RS can help maximize space and improve the efficiency of urban farming operations. This technology supports sustainable agriculture by enabling high-density crop production in controlled environments. While the AS/RS is often used to store finished produce in trays, pallets, or even large bags, such as rice or flour, utilizing an automated storage system to manage ingrowth food can significantly transform the entire food cycle from start to end.

Cremated Remains

A unique and socially significant application of an AS/RS is in the storage of cremated remains within an automated columbarium. With cremation rates rising worldwide, traditional, non-automated columbaria face spatial limitations, especially in urban areas. In an automated system, the AS/RS enables vertical storage up to 20 meters high, optimizing space efficiency while providing a dignified and organized solution for families.

Read More

Case Study: Jigenji Temple

Insights: Innovating Remembrance – The Elegance of the Automated Columbarium

Luggage

Ever wondered what happens to your checked baggage before it’s loaded onto the aircraft? After inspection, it often waits in an intermediate holding area—on conveyors, carts, or even an Automated Storage and Retrieval System (AS/RS). Specifically, an Early Baggage Storage (EBS) system efficiently manages this process, ensuring seamless airport operations. Suitcases are placed on trays and stored in a rack, then retrieved at the right time for loading onto the aircraft.

Read More

Case Study: Early Baggage Storage (Daifuku—Airport Technologies Website)

Very Long Objects

While the AS/RS is commonly associated with pallets and cases, it can also handle exceptionally long objects—often exceeding six meters in length. These can include pipes, metal bars, construction materials, window sashes, lumber, aircraft parts, train components, furniture, and more. Without automation, these items are often stored on the floor, leading to challenges such as excessive floor space usage, difficulty in just-in-time supply, workplace safety risks, and poor inventory management accuracy.

Read More

Case Study: Sakuma Special Steel

Insights: Discovering the Ideal Storage Solution for Long Loads and Materials

Summing It Up

The humble AS/RS is far more versatile and impactful than one might think at first glance. While traditionally associated with storing cases and pallets, its applications extend into unexpected and transformative areas, from vertical farming to airport baggage handling and even the dignified management of cremated remains.

As industries continue to evolve, so too will the ways in which the AS/RS can and will be used. Advances in automation, AI, and smart logistics will likely drive even greater innovation, allowing these systems to handle an even broader range of materials with increased efficiency, precision, and adaptability. Whether optimizing warehouse operations, enhancing urban agriculture, or solving space constraints in a columbarium, the AS/RS continues to prove to be an indispensable technology across sectors.

AS/RS Experience

With over 35,000 Daifuku AS/RS stacker cranes deployed over the years, it's safe to say that we know a thing or two about successfully deploying an automated warehouse. We invite you to learn more about the applications and benefits of AS/RS solutions through our dedicated page.

Stuart Oliphant

International Planning Group, Intralogistics Division, Daifuku

Based at Daifuku’s Tokyo Head Office, Stuart joined the company in 2016, bringing his skills to the Corporate Communications Department. In 2022, he transitioned to the Intralogistics Division, where he now plays a central role in driving marketing and sales support initiatives. From shaping content for the Intralogistics section of the Daifuku website to contributing to the company’s global LinkedIn presence, Stuart works across teams to help communicate Daifuku’s automation capabilities to the world.