Production Tool, Die & Mold Management

There are many kinds of molds and dies used when manufacturing materials such as metal, resin, glass, and rubber. Even after finishing mass production, the molds and dies must be saved for the creation of spare parts. As manufacturing plant operations continue, the amounts needed to be stored will only increase. At many plants, molds and dies are just piled up on the floor or stored on shelves. But as their number increase, the following problems become noticeable.

-

Lack of storage space

A continuously growing number of molds and dies, and not enough storage space.

-

Mold and die switching takes additional time

Finding and then retrieving the appropriate mold or die is time-consuming.

-

High risk of damage

Constantly shuffling molds and dies to get to the correct one increases the risk of damage over time. And a damaged mold or die can lead to a faulty product.

-

Unsafe work environment

Retrieving a mold or die poses a high risk of accident.

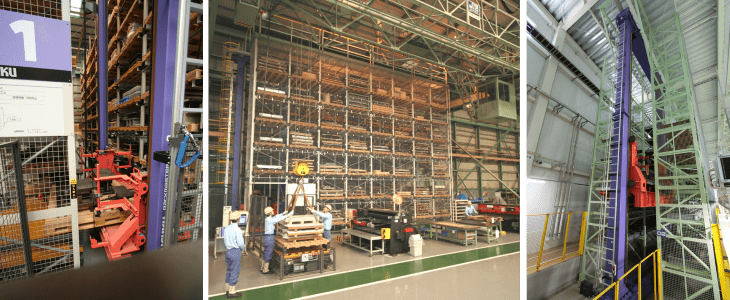

AS/RSs Solve the Problems of Space, Work Efficiency, and Safety.

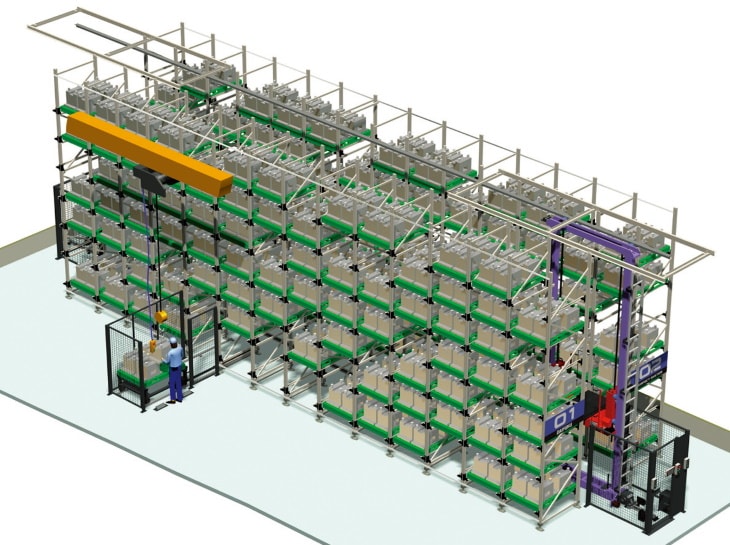

Storing molds and dies in an automated storage and retrieval system (AS/RS) enables inventory management to be easily handled with a computer and expedites the storage and retrieval processes.

By making use of the available vertical space, mold and die storage capacity increases. Easy access to all shelves enables rapid retrieval.

-

EFFICIENCY: A WMS can take care of storage management

A WMS oversees the storage area. Increasing efficiency due to not needing to search for molds or dies by eye.

-

SAFETY: No dangerous retrieval work

An AS/RS will handle retrieval operations. Accident risk decreases as workers need only wait at the conveyor station which is set at an easy place to work.

-

QUALITY: Avoid risk of mold and die damage leading to faulty products

Molds and dies do not touch each other while stored on the pallet and thus have a significantly reduced risk of damage.

-

MULTI-TASK: Storage of other items also possible

Provided they are within shape and weight parameters, other production tools or raw materials can also be stored in the AS/RS.

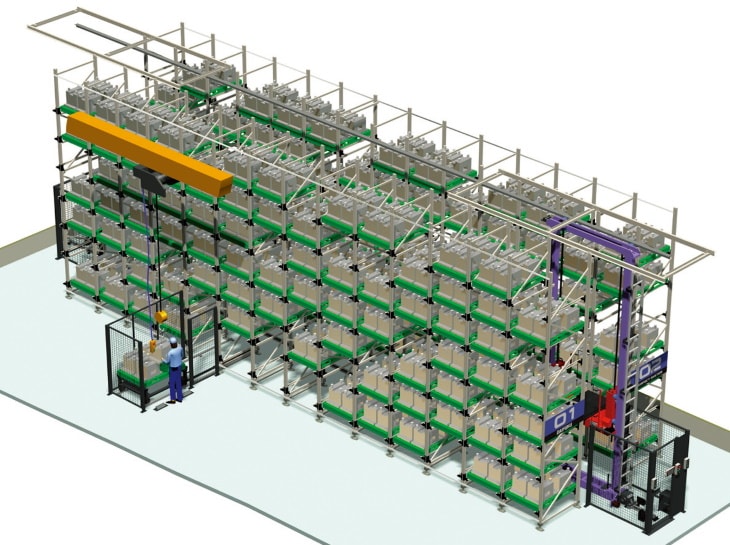

Mold and Die Storage AS/RS Model

|

Configuration | 2 banks x 14 bays x 7 levels |

|---|---|---|

| Size | 22 x 4 x 8 meters | |

| Floor area | 88 m2 | |

| Load size | 1,100 x 1,100 x 800 millimeters | |

| Load weight | 1,000 kilograms | |

| Storage capacity | 194 pallets | |

| Equipment | 1x stacker crane 1x electric shuttle cart |

Typical products

Contact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact UsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact Us