History

Since its foundation in 1937, Daifuku has lead material handling industry. We have continuously developed and introduced various innovative products. We strive to take up challenges to provide products and services that benefits society.

1937-1949

| 1937 |

Founded as Sakaguchi Kikai Seisakusho Ltd. |

|---|---|

| 1939 |

Establishes the Mitejima Factory (photo). In 1940, the Company headquarters moves from Owada to Mitejima. |

| 1944 |

Changes Company name from Sakaguchi Kikai Seisakusho to Kanematsu Kiko. |

| 1946 |

Manufactures cereal grinding machines, ice shavers, and movie theater seats to remain in business after World War II. |

| 1947 |

Changes Company name from Kanematsu Kiko to Daifuku Machinery Works Co., Ltd. Begins manufacturing the Stacker. |

| 1948 |

Begins production of the Piler (photo) and the Slatveyor. |

1950-1959

| 1952 |

Forms a technical partnership with Buhler Brothers of Switzerland. Starts production of the Bulkveyor. |

|---|---|

| 1953 |

Provides Japan's first Bulkveyor (photo) to Yokkaichi Warehouse. |

| 1957 |

Delivers the first Webb conveyor system to the Kariya factory of Toyota Auto Body. |

| 1958 |

Delivers engine testing conveyor to Toyota Motor headquarters. Engine testing becomes fully automated. |

| 1959 |

Delivers the Webb conveyor system (photo) to Toyota Motor's Motomachi factory, Japan's first factory to exclusively manufacture passenger automobiles. |

1960-1969

| 1961 |

Lists stocks on the second section of the Osaka Stock Exchange. |

|---|---|

| 1962 |

Lists stocks on the second section of the Tokyo Stock Exchange. |

| 1963 |

Inaugurates the Komaki Plant. Manufactures the first Japan-made ten-pin bowling machine (photo) in collaboration with Bowl-Mor Company, Inc., U.S. |

| 1964 |

Enacts the Company creed Hini Arata |

| 1965 |

Manufactures and sells the Prontow (photo), Japan's first AGV. Starts to manufacture and sell the mesh box pallet - the Palletainer. |

| 1966 |

Produces Japan's first automated high-rise Rackbuil System (photo) at the Komaki Plant, and delivers it to Matsushita Electric Industrial Co., Ltd. |

| 1968 |

Sets the company slogan as “Challenging for Automated Operations” |

| 1969 |

Lists stocks on the first section of the Nagoya Stock Exchange. Delivers Japan's first online computer-controlled Rackbuil System to Asahi Kasei Corporation (photo). |

1970-1979

| 1970 |

Acquires an industrial site in Hino-cho, Shiga Pref. and begins land development for a 1.2 million-sq.m industrial park (photo). Showcases the Prontow and Palletainer at the Japan World Exposition. |

|---|---|

| 1971 |

Delivers the world largest Rackbuil System to Toyota Motor. |

| 1972 |

Develops the Compact System, a unit load AS/RS and delivers the system to Fujimura Iron Works (photo). Produces the Roll Box Pallet. |

| 1973 |

Delivers Japan’s first refrigerated AS/RS, which operates at -40 degrees Celsius, to the cold storage company Hosenreizou. Develops a mini load AS/RS, the Bucketbuil System, and delivers it to Matsushita Seiko Co., Ltd. |

| 1974 |

Receives an order for a Rackbuil System for a petroleum refining plant from an Algerian government-owned company. |

| 1975 |

Establishes Daifuku Koei Co., Ltd. to handle installation and after-sales service. Establishes Contec Co., Ltd., which specializes in industrial computers, and Paltec Co., Ltd. specializing in software development. Completes construction of the Hino Plant’s (now Shiga Works) Factory C. Receives an order from Iran for a cold storage system. |

| 1976 |

Develops an automated sorter―Sorting Master―and delivers the first system (photo) to a Heiwado distribution center. |

| 1977 |

Launches the car wash machine business. |

| 1978 |

Delivers Japan’s first book conveying system, the Telelift (photo above), to Chuo University’s library. Installs the first Hanger Rail System, which measured 2,200 meters long, in a newly-built distribution center of Renown Incorporated. Delivers a copying machine production line system (photo below) to Konishiroku Shashin Kogyo. |

1980-1989

| 1980 |

Installs a large Bucketbuil System (photo above) with over 100,000 totes in Nissan Motor's Sagamihara Parts Center. Daifuku's trolley conveyor (photo below) takes an active role in the major repair of the Great Buddha Hall of Todai-ji, a temple and national treasure of Japan. |

|---|---|

| 1981 |

Introduces the microcomputer-installed car wash machine, the Waxmor 303 (photo). Delivers an Automated Conveying System for Tray Services to Kagaya Group in Ishikawa, Japan. |

| 1982 |

Delivers a state-of-the-art factory automation (FA) system (photo) comprising an AS/RS and AGVs to FANUC's Motor Factory. |

| 1983 |

Establishes the first global subsidiary, Daifuku U.S.A. Inc., in Chicago. Develops the electrified monorail system, Ramrun (photo), and delivers the first system to Toyota Motor’s Motomachi Factory. |

| 1984 |

Develops the Clean Stocker, the Cleanway (photo) and the Clean Shuttle for semiconductor production lines. Changes the company name from Daifuku Machinery Works Co., Ltd. to Daifuku Co., Ltd. |

| 1985 |

Establishes Daifuku Canada Inc. in Toronto, Canada. |

| 1986 |

Establishes Daifuku Mechatronics (Singapore) Pte. Ltd. in Singapore. Develops the Digital Pick System (photo), a pick-to-light system that uses digital displays to guide users. |

| 1987 |

Develops the linear motor driven Ramrun, known as the Ramrun LIM10, and delivers the first system to Toyota Motor. Delivers the first Picking Cart System (photo) using IC cards and optical transmission to the Chubu Product Center of the Shiseido Logistics Company, Ltd. Develops the Fine Stocker, a mini load AS/RS. |

| 1988 |

Collaborates with Nippon Steel to develop and sell automated warehouse systems. Develops the Running Flow (now the Magic Flow), a storage system combining a low-capacity motor and air sequencer. |

| 1989 |

Develops a friction-driven automobile assembly and transport system, the Silent Assembly Line (photo). Establishes Daifuku Europe Limited in London, U.K. |

1990-1999

| 1990 |

Establishes ESKAY Corporation for the sale of logistics systems in the U.S. |

|---|---|

| 1991 |

Releases the Conveying Flow System, a roller conveyor system. Develops the world's first automated replenishment system and delivers to Shiseido's Kyushu Distribution Center. Integrated Contec Co., Ltd. with Paltec Co., Ltd. to form Contec Co., Ltd. Establishes Daifuku (Thailand) Ltd. in Bangkok. |

| 1992 |

Develops the Ski Sorter (photo), an automated sorting system for small goods, and the fully automated mobile rack system Magic Aisle. |

| 1993 |

Develops the Ramrun-HID (photo), the world's first electrified monorail system with non-contact power supply. Delivers the system to Kanto Auto Works' Iwate Plant. Releases the Magic Thru, a tunnel-type car wash machine. |

| 1994 |

Develops Magic Vehicle, an automatic guided vehicle. Opens Hini Arata Kan (photo), one of the world’s largest material handling and logistics demo centers. Establishes Daifuku (Malaysia) Sdn. Bhd. in Malaysia. Contec obtains ISO 9001 certification, a standard of international quality management. |

| 1995 |

Daifuku Thailand’s Chonburi Plant (photo) commences operation. Daifuku completes its first M&A by acquiring 100% of the stock of Taiwan-based Pioneer Automation Co., Ltd. and making it a subsidiary. Establishes P.T. Daifuku Indonesia. Electronics Division, ASD Division, and other divisions obtain ISO 9001 certification. Establishes Clean Factomation, Inc. in Korea. |

| 1996 |

Establishes Daifuku Magic Technology Corporation for the sale of car wash machines. |

| 1999 |

Relocates the Osaka Plant functions to the Shiga Works. The Komaki Works and Shiga Works obtain ISO 14001 certification, the International environmental management standard. Delivers a quake-absorbing AS/RS (photo) to Nippon Suisan Kaisya, Ltd.’s Tokyo Logistics Center |

2000-2009

| 2000 |

Integrates Daifuku Magic Technology and Daifuku Unix to establish a 100% owned subsidiary. Establishes a business unit, eFA Operations, for the semiconductor and flat panel display (FPD) industries. |

|---|---|

| 2001 |

Receives the first order for a 300-mm wafer transport system from South Korea. Releases the first self-serve drive-thru car wash machine Waxmor Twinthru. |

| 2002 |

Receives an order for a 5th generation FPD transport and storage system. Establishes first subsidiary in China - Daifuku (Shanghai) Ltd. Delivers Japan's largest automated book storage system (photo) to store and retrieves books at the Kansai-kan of the National Diet Library. |

| 2003 |

Establishes Daifuku Automation (Tianjin) Co., Ltd. in China. Establishes Daifuku Carwash-Machine Korea Inc. Establishes Daifuku Qubica Ltd. to handle sales of bowling equipment. Launches an on-call 24-hour System Support Center at the Shiga Works. |

| 2004 |

Formulates the Corporate Code of Conduct. Establishes the Compliance Committee. Acquires the material handling business from Kito and establishes Daifuku Logistics Technology Co., Ltd. Establishes Contec EMS Co., Ltd. Jointly develops E-DIP (photo), an eco-friendly automobile paint system, with Taikisya Ltd. Develops the Fine Stocker, a super-fast mini load AS/RS that delivers the world's fastest speed of 500 m/min. Launches the DREMOS (Daifuku Remote Monitoring Service), offering a 24 hour-365 day remote monitoring service to customers equipment―the first of its kind in the industry. Establishes Daifuku Automation (Guangzhou) Co., Ltd. |

| 2005 |

Establishes the first production subsidiary in China, Jiangsu Daifuku Rixin Automation Co., Ltd. Establishes Daifuku India Private Limited. |

| 2006 |

Establishes Taiwan Daifuku Co., Ltd. (photo: opening ceremony) |

| 2007 |

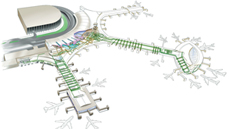

Contec listed on the second section of the Tokyo Stock. Creates a new Daifuku lapel pin. Regains an A minus (A-) rating for corporate bonds after a decade with a BBB+ rating. Releases the eco-friendly car wash Waxmor Abient. Acquires all shares of Jervis B. Webb Company and enters the airport baggage handling business. (photo: memorial plaque given by Jervis B. Webb Company) |

| 2008 |

Integrates two affiliates in Taiwan leading to Taiwan Daifuku taking over all existing business operations in the region. Acquires 68.7% of the shares of Osaka Machinery Works shares making it the newest Japanese subsidiary. Develops the DUOSYS (photo), a high-throughput mini load AS/RS, offering a maximum storage/retrieval throughput of up to 2,200 cases per hour. Redevelops the Komaki Works as a distribution complex under the name of DRE (Daifuku Real Estate) Komaki Center. The site now houses an office building and two distribution centers. |

| 2009 |

Obtains OHSAS 18001 certification for occupational safety and health management at four sites in Japan: Osaka Headquarters, Tokyo Head Office, Shiga Works and Komaki Works. Three affiliates operating in South Korea, ATS Co., Ltd., MIMATS Co., Ltd. and Daifuku Carwash-Machine Korea Inc., merge together and make a fresh start as Daifuku Korea Co., Ltd. Integrates three affiliates - Daifuku QubicaAMF Co., Ltd., Daifuku Unix Corporation and Kyushu Daifuku Corporation - with the material handling equipment rental operations of Daifuku Business Service Corporation. The newly formed Daifuku Plusmore Co., Ltd., handles consumer products. Acquires the material handling systems service business and related assets from Komatsu Utility Co., Ltd. and Komatsu Forklift ILD Co., Ltd., a member of the Komatsu Utility Group. Opens a new plant of Daifuku Thailand in Pinthong (photo). |

2010-2019

| 2010 |

Revamps six affiliates in China and launches a new operating structure centered on the new subsidiary Daifuku (China) Co., Ltd. (photo above: opening ceremony) Launches Environmental Enhancement Management Committee. Opens the Anzen-Taikan Dojo facility at Osaka Headquarters where trainees learn the importance of safety by simulating the occupational hazards of installation. Daifuku aims to enhance safety awareness and eradicate workplace accidents. Delivers a fresh produce sorting system (photo below) to JA Kumamotoshi―Japan's largest such system. Shiga Works receives an award for outstanding greening performance from the Japan Greenery Research and Development Center. Forms a business partnership with Austria-based Knapp AG. |

|---|---|

| 2011 |

Acquires the manufacturing, sales and service business for car wash machines from YASUI Corporation. Establishes Daifuku Webb Holding Company in the U.S. Establishes Daifuku Manufacturing Technology Co., Ltd., merging two Japanese affiliates – Daifuku Manufacturing Expert Co., Ltd. and Daifuku Machinery Works Co., Ltd. Logan Teleflex (UK) Ltd, along with Logan Teleflex (France) S.A. and U.S.-based Logan Teleflex, Inc., become wholly owned subsidiaries. Formulates the Daifuku Environmental Vision 2020. Develops a high-throughput digital picking system and delivers the system (photo above) to Miyagi Co-op’s Narita Set Center. Develops the Baggage Tray System (photo below) for airport baggage handling and sorting. The system offers one of the world’s fastest transport velocities at 600 m per minutes. |

| 2012 |

Acquires Hitachi Plant Technologies' cleanroom material handling system service business. Austria-based Knapp becomes an equity-method affiliate. The top car wash machine manufacturer in South Korea, Hallim Machinery Co., Ltd. becomes a wholly-owned subsidiary. Establishes Daifuku (Suzhou) Cleanroom Automation Co., Ltd. Daifuku Webb Holding Company acquires Elite Line Services, LLC, a provider of operations and maintenance support for baggage handling systems. Establishes the Daifuku Eco-Products Certification Program. Develops the FALS (Flexible Assembly Leveling System) for automobile assembly lines, allowing for adjustments of the car platform to desired heights (photo above). Releases a new product called “audit” to support dispensaries. Develops the Shuttle Rack, a new mini load AS/RS (photo center). Develops an automated system for freezer lockers that can operate at -35℃ and applied it to develop the world's first AS/RS for fast freezing fish products (photo below). Delivers a Nitrogen Purge System that uses nitrogen gas to prevent deterioration of semiconductor wafers. |

| 2013 |

Establishes Daifuku de Mexico, S.A. de C.V. Establishes a new brand message―Always an Edge Ahead. Daifuku Webb Holding Company acquires Wynright Corporation. Begins operations of the Daifuku Shiga Mega Solar (photo) at the Shiga Works, with generating capacity of 4,438kW. |

| 2014 |

Develops the Area Management System to enhance the safety of high-speed vehicle systems. It receives the ISO 13482 international safety standard. Changes share trading unit from 500 to 100. Joins the United Nations Global Compact. Develops the Smart Stocker Quattro, a high-throughput mini load AS/RS (photo above), which has two carriages on one stacker crane that can move independently of each other. Acquires 80% of the outstanding shares of New Zealand's BCS Group Limited to expand business in Southeast Asia and Oceania. Develops the SPDR (Spider), a temporary storage/sortation system (photo below) for parts logistics operations at automobile factories. |

| 2015 |

Daifuku Webb Holding Company changes its name to Daifuku North America Holding Company. Daifuku was ranked No.1 for sales in 2014 in the material handling industry, according to U.S.-based magazine Modern Materials Handling's 'Top 20 System Supplier 2015' report. Paid-in capital increases from 8 billion yen to 15 billion yen. |

| 2016 |

Commences sales of the D-PAD (photo above), the world's first wireless charging system for forklifts. Delivers Myanmar’s first AS/RS to a pharmaceutical company. Daifuku (China) Manufacturing Co., Ltd. relocates its factory, facilitating a 2.5-fold increase to production capacity. (photo below: new head office and factory in Shanghai) |

| 2017 |

Daifuku North America Holding Company moves its headquarters to Novi, Michigan. (photo: new headquarters building) The Shiga Works receives a Factory Greening Award form Japan’s Ministry of Economy, Trade and Industry. As a result of the public offering, paid-in capital increases from 15.0 billion yen to 31.8 billion yen. |

| 2018 |

Sells all shares of Knapp AG. Concludes a strategic global partnership with Fast Retailing aimed at establishing comprehensive logistics services over the medium to long term. Receives the Environment Minister’s Award for Global Warming Prevention Activities. |

| 2019 |

Acquires 100% of the shares of India-based Vega Conveyors and Automation Private Limited. Acquires 80% of the shares of Scarabee Aviation Group B.V., a provider of airport security screening equipment. Acquires 100% of the shares of Intersystems (Asia Pacific) Pty. Ltd., a provider of information management systems for airports. Establishes Daifuku Intralogistics Vietnam Co., Ltd. in Vietnam. Completes the new office building (photo) at the Osaka Headquarters. |

2020

| 2020 |

Wynright commences operations at the newly built Daifuku Intralogistics North America Works in Hobart, Indiana. The new facility consolidated two manufacturing facilities into one, which enables a doubling of production capacity. (photo above: the new facility in Indiana) Establishes Daifuku Cleanroom Automation America Corporation in the U.S. Delivers Self Bag Drops (SBDs) to Japan Airlines. (photo below: SBDs at Haneda Airport’s Terminal 1) |

|---|---|

| 2021 |

Forms a business partnership with German-based AFT Industries AG. Formulates the Daifuku Environmental Vision 2050. Forms a partnership with Rakuten Group, Inc. Daifuku's management philosophy revised to 'Automation that Inspires' |

| 2022 |

Receives the METI Minister’s award for Corporate Governance of the Year 2021. Contec Co., Ltd. becomes wholly owned subsidiary. Reopens the full-scale material handling and logistics demo center Hini Arata Kan, adding new exhibits featuring Daifuku’s latest material handling systems and equipment. Commences operations at new manufacturing plant for airport systems in North America. Transitions all electricity used at Shiga Works to be from renewable sources. |

| 2023 |

Daifuku (Suzhou) Cleanroom Automation Co., Ltd. (China) constructs new manufacturing plant, expanding production capacity. (photo above) Issues zero coupon convertible bonds with proceeds reaching approximately 60 billion yen. Completes construction of second high-rise testing facility at Shiga Works (photo below) and begins operational testing of newest high-speed, high-rise automated storage and retrieval system (AS/RS) stacker cranes. |

| 2024 |

Changes Fiscal year end from March to December. Announces Driving Innovative Impact 2030 and new four-year business plan for 2027. Begins renovations of Shiga Works to increase production capacity and improve logistics efficiency. Japan Ministry of the Environment certifies the conservation pond and environment learning plaza at Shiga Works as a "nature-friendly site." Shiga Works receives the Minister of Health, Labor, and Welfare Award for Human Resources Development in 2024. |