Unit Load AS/RS

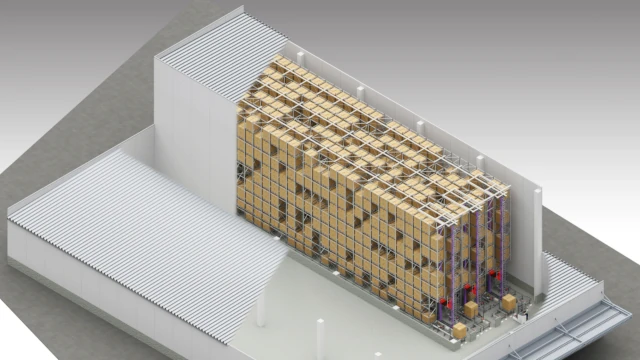

Renowned for its high-density pallet storage, rapid operation, and adaptability, Daifuku’s Unit Load Automated Storage and Retrieval System (AS/RS) stands as one of the world's top-selling automated storage and retrieval systems. Its versatile design spans up to 40 meters, allowing customization to seamlessly integrate into your specific installation environment and operational requirements.

Features

1. Fast and Dependable

Daifuku offers a variety of AS/RS stacker cranes to fit your specific load profile and weight, building dimensions, and operating environment. All our AS/RSs feature high-quality drives for fast, smooth, and reliable performance.

2. Advanced Control System

Our local intelligent network control system provides a comprehensive solution, from front-end controls to full-scale inventory management computer systems. Our software offers complete control over stacker cranes and their peripheral load-handling systems, monitoring the system in real time to aid in troubleshooting and manage auxiliary equipment such as quantity indicator displays for order picking.

3. Improved Operational Efficiency

The high-speed stacker crane of the Daifuku Unit Load AS/RS automatically stores and retrieves loads with exceptional speed and efficiency. This not only significantly reduces cycle times but also minimizes the need for forklifts and associated traffic. The stacker cranes further optimize operations by employing energy-efficient practices, including power regeneration and low electricity consumption.

Load Handling

From industrial pallets to odd-shaped loads, the Daifuku stacker crane can handle an array of different items.

-

Closed pallets

A pallet with a closed bottom surface such as the JIS T11 pallet (1,100 x 1,100) and UK pallet (1,000 x 1,200). -

Euro pallets

A skid pallet widely used in Europe and Asia. The standard size is 800 x 1,200 and 1,000 x 1,200. -

Box pallets

A four-legged box pallet commonly used for storing machine parts (handling dependent on shape of box feet). -

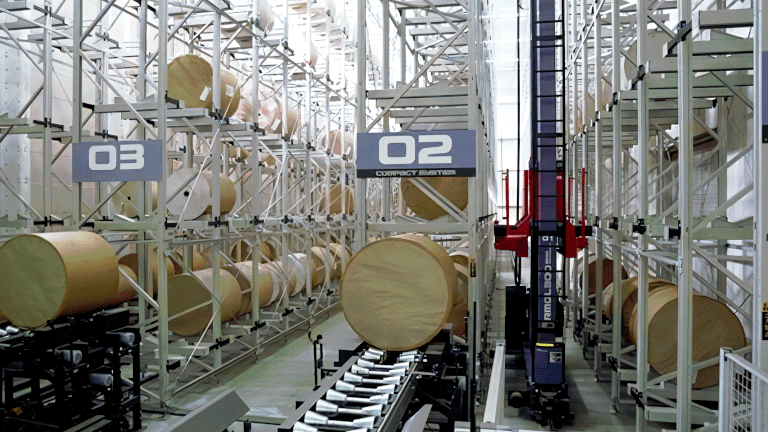

Roll-shaped loads

Roll-shaped products such as paper rolls, film sheets, textile rolls, and carpets can be handled. -

Long objects

High density storage of long pipes, bars, and plates up to 6.2 m long. (Case Study) -

In-progress car bodies

Painted car body buffer at an automotive plant. (Case Study)

Special Environments

Daifuku offers a range of models tailored to match diverse installation environments and the characteristics of stored items. With a proven track record, our automated warehouses are deployed in various specialized environments. These include freezing specifications highly sought after in the food industry, high-temperature specifications ranging from 40 to 55°C for chemical product aging processes, and oil-resistant specifications crucial for installations around machine tools.

-

Fresh and frozen environments

A cold-resistant stacker crane designed for handling frozen foods in environments ranging from -5°C to -30°C. -

Cleanroom environments

Cleanroom application is available to meet ISO Class 6~7 requirements from food, pharmaceutical and precision equipment manufacturers. Click here for systems for ultra-clean environments, such as semiconductor and LCD manufacturing sites. -

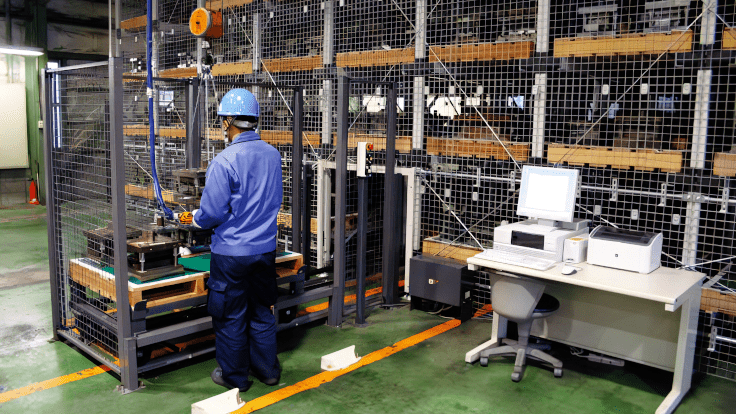

Oily and dusty environments (FMS)

A specially designed, highly accurate stacker crane facilitates 24-hour automatic supply and collection of jigs to and from machining centers. The system incorporates specialized features to ensure precise and stable AS/RS operations in oily and dusty environments.

Configuration

-

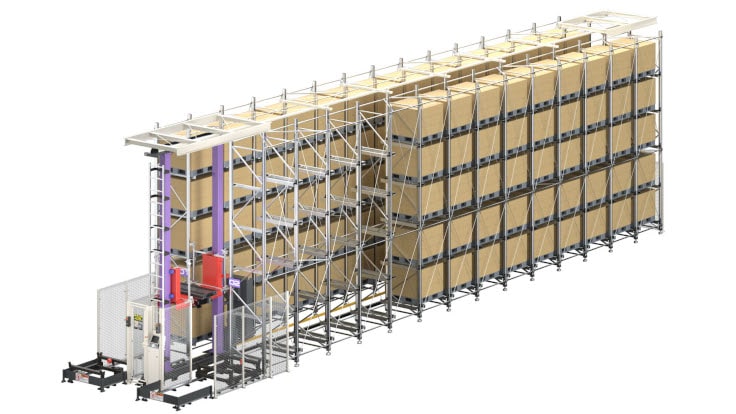

Single-deep AS/RS

Standard AS/RS configuration. One stacker crane with access to two rack rows (one on each side). -

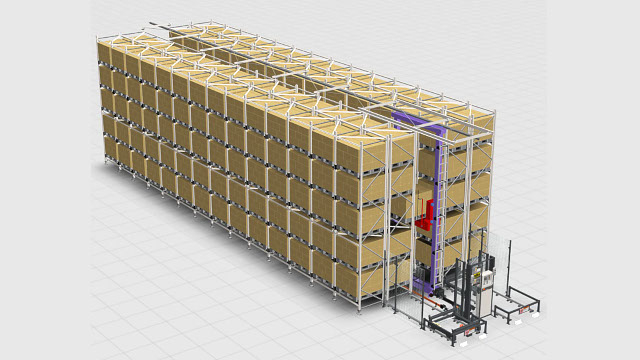

Double-deep AS/RS

A single stacker crane accesses four rack rows (two on each side). Great for high-density storage with low to medium throughput requirements. -

Dual crane AS/RS

Two stacker cranes operate simultaneously in the same aisle to maximize throughput capacity and resiliency. -

Earthquake countermeasures

Additional stoppers, special racking, and other countermeasures can be applied to minimize earthquake damage. Learn more.

Add-ons

-

Shuttle Cart

Electrically powered cart transports pallets to the loading and unloading point for the stacker crane. -

End-of-aisle conveyors

Conveyors automatically transport pallets to and from load and unload stations. Can also transfer pallets to and from STVs. -

Rack side conveyor

Placing the input and output conveyor beside the AS/RS streamlines the supply of loads to press and processing machines. -

Sorting Transfer Vehicle (STV)

The STV, a rail-guided vehicle system that transports and sorts pallets, connects AS/RS aisles to in and out conveyors. -

Case picking robot

Combining case picking robots before and after the Unit Load AS/RS automates the palletizing and depalletizing of case goods. Daifuku offers comprehensive solutions that cover processes from the upstream operations of automated warehouses to shipping. -

Rack-side pick-to-light

The sides of the AS/RS rack are used as picking windows. A sliding shutter is installed at each picking window to ensure operator safety by preventing stacker crane access while the shutter is open. Lean more.

Model Systems

-

Explore three model systems showcasing the movement of an AS/RS and its peripheral equipment. Find your solution with Daifuku.

-

Contact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact UsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact Us