Multi Shuttle Vehicle AS/RS – Shuttle Rack M

Daifuku's multi shuttle system, the Shuttle Rack M, is a fast, vehicle-type AS/RS designed to provide temporary storage, sorting and sequencing functions. It is perfect for the following needs:

Manufacturing

- Buffering products from manufacturing lines and feeding to palletizing robots by product group

- Parts picking for high-mix, low-volume production

- Picking parts for customer orders at a maintenance parts center

Distribution

- Buffering between primary batch picking and secondary order assorting

- Buffering finished order cartons/totes until shipment and feeding by delivery group

- Buffering depalletized products and feeding by sequence or group to create mixed pallets

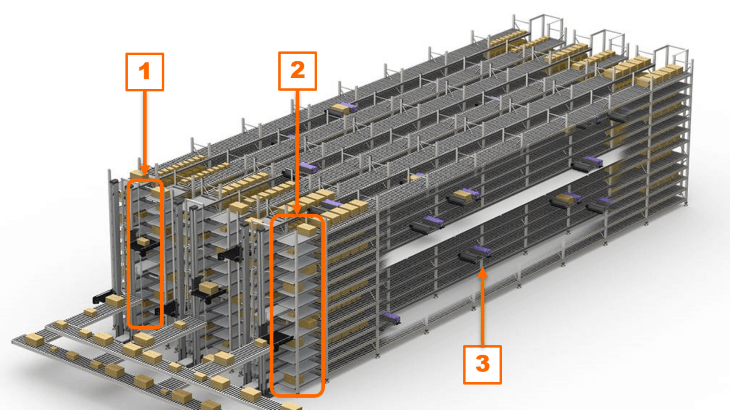

System Configuration

Features

High-density storage with flexible location management

The Shuttle Rack M can handle multiple types of containers and cardboard boxes. A free-allocation management function by the controller automatically adjusts the storage location according to the size of the load, allowing for high-density storage.

Plastic containers

Euro containers, collapsible containers and other industry standard containers.

Carton boxes

Various carton box sizes.

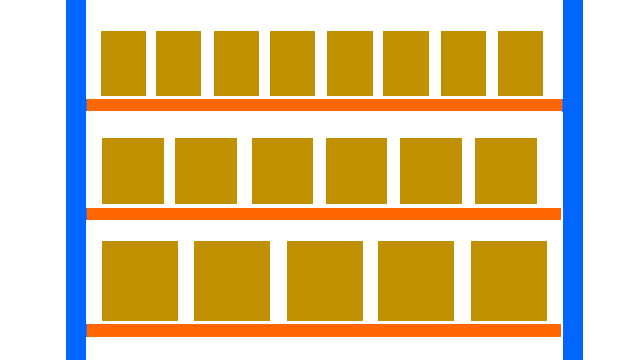

Free allocation

One type of shelving rack can accommodate a range of storage patterns according to load size, providing high storage density and flexibility.

Easy Maintenance

Faulty shuttles can be replaced with little disruption to the system. Other shuttles continue to operate while maintenance is being performed on one shuttle. By controlling the number of active shuttles, maintenance can be systematically performed on each shuttle without interrupting the handling process.

Energy Saving

The system has one shuttle vehicle installed on every level. Each shuttle travels at high speeds to quickly store and retrieve loads. By using lightweight vehicles to transport loads, the Shuttle Rack M consumes 60% less power per cycle than conventional crane systems.

Variations

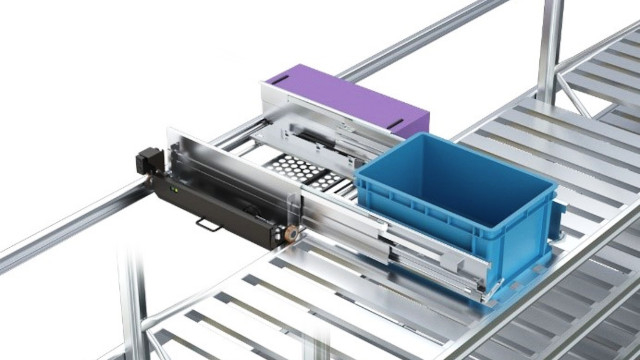

Extractor

Single-deep shuttle

One shuttle with access to two rack rows (one on each side).

Double-deep shuttle

One shuttle with access to four rack rows (two on each side).

Special environment

Cold storage model

The cold version operates in up to -30-degree environments and is ideal for buffering and sorting frozen foods.

Add-ons

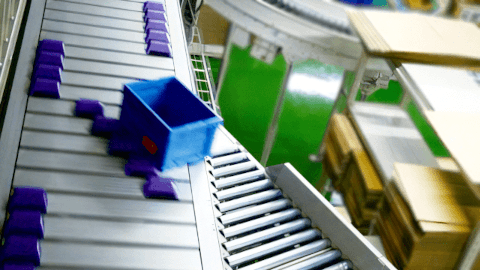

Diverting conveyors

The accurate diverting of loads into the right shuttle aisle is essential to a successful system consisting of multiple aisles. Daifuku offers the Shuttle Rack system with the best diverting solution to meet each customer's needs.

Slide-shoe diverter – Magic Cross Conveyor

Slide-shoe slat conveyor that handles up to 2,400 cases per hour. Its right angle merging greatly reduces system footprint.

High-speed roller diverter

Urethane rollers ensure that loads are gripped securely and divert them quickly to Shuttle Rack lanes. Ideal for a Shuttle Rack system consisting of multiple aisles for high throughput.

Piece Picking Systems

Goods-to-person pick station – Quick Pick Station

A Quick Pick Station smoothly provides an inventory tote supplied from Shuttle Rack M and a pick-to tote together in front of a picking operator, eliminating walking time and fatigue.

Piece picking robot

A Shuttle Rack M feeds inventory totes to a piece picking robot to transfer items into order collection totes.

Sorting Systems

Put-to-light sorting system

A Shuttle Rack M buffers the batch-picked items in totes and supplies them in groups to a put-to-light sorting system for order consolidation.

Sorter

A case sorter diverts cases from a Shuttle Rack M according to shipping delivery route.

Palletizing System

Palletizing robot

A Shuttle Rack M buffers products from mixed production lines and feeds them to a palletizing robot by SKU/lot group to create single-SKU pallets.

Reference

Logisteed East Japan, Ltd.

3PL service provider uses a Shuttle Rack solution to improve order preparation efficiency at a shoe distribution center.

Coca-Cola Bottlers Japan Inc.

Coca-Cola deploys a Shuttle Rack M to facilitate sequenced and group palletizing of cases for shipping.

Komatsu Ltd.

Introduces a Shuttle system, improving the efficiency of both inventory storage and picking operations.

Trusco Nakayama

Professional tool wholesaler installs a Daifuku Shuttle Rack M as sorting and shipping buffer to streamline operations.

Contact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact UsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact Us