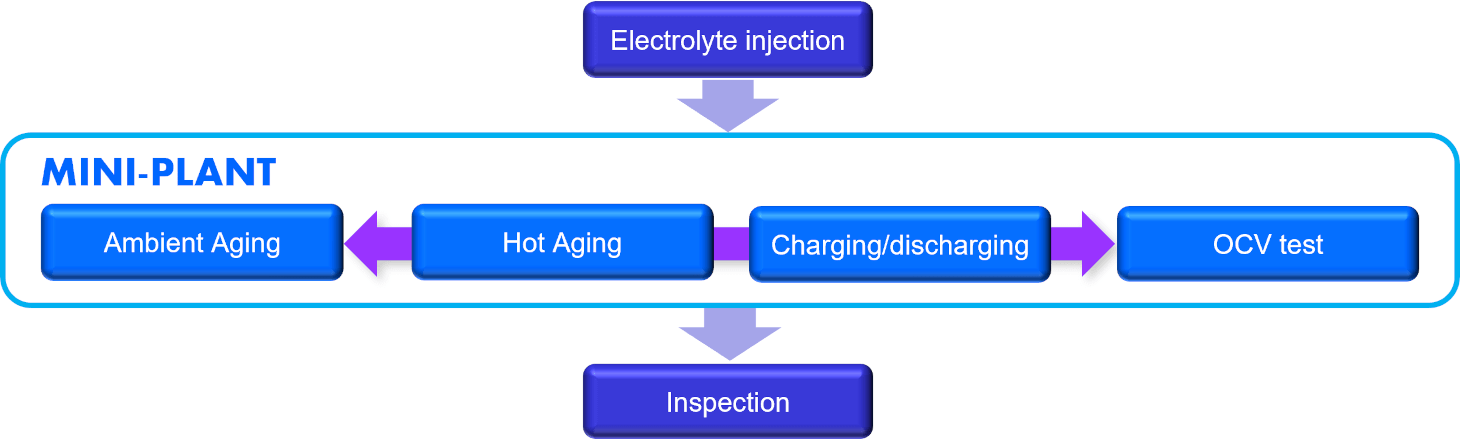

Battery Aging Solution

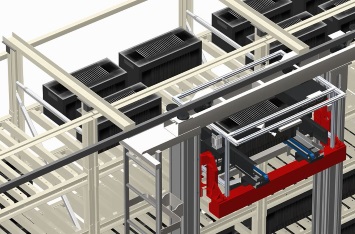

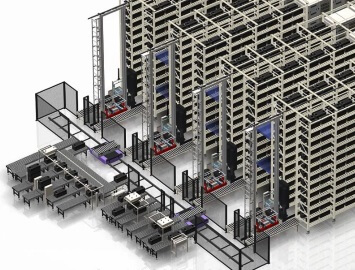

Daifuku offers the Mini-Plant system for smooth and efficient handling within normal temperature aging, hot aging, charging, discharging, degassing, testing and inspection processes at battery production plants. With the Mini-Plant, these processes are consolidated in one AS/RS, eliminating the need for complex conveying and stacking devices. Once a work-in-process (WIP) enters the Mini-Plant, all processes are performed within the same aisle.

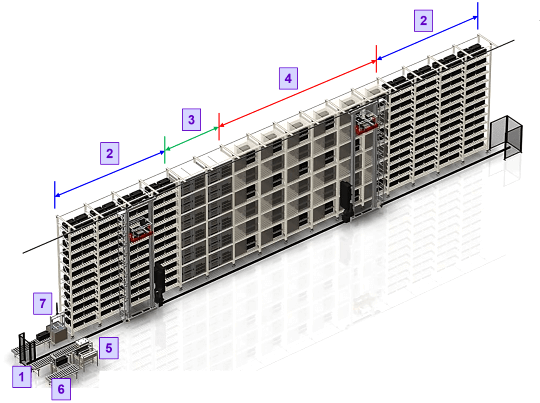

System Configuration

|

1 | Inbound line |

|---|---|---|

| 2 | Normal aging zone | |

| 3 | Charger/discharger | |

| 4 | Hot aging zone | |

| 5 | OCV tester | |

| 6 | Rejection line | |

| 7 | Water tank |

Features

Flexible & Quality-Conscious

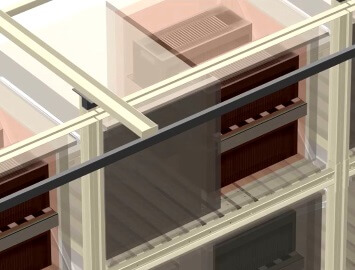

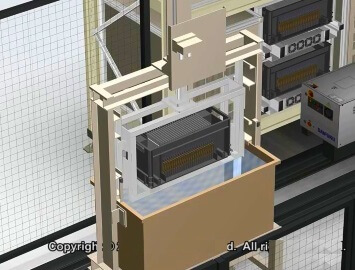

Rack locations in the hot aging zone (#4) are equipped with individual shutters to ensure a consistent and precise aging process.

Individual shutters also add flexibility to the system as each location can be changed easily between normal and hot aging. As a result, production order and process reorganization is simplified and storage location modes can be configured according to production needs.

High-Throughput & Resilient

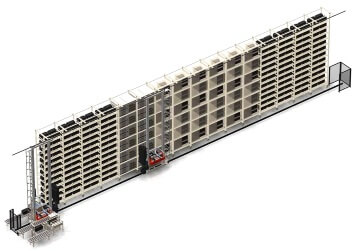

Two stacker cranes operate simultaneously in the same aisle to increase productivity and throughput. Increased efficiency results in maximized utilization of the charger and discharger.

The dual stacker crane system is also beneficial for redundancy because one stacker crane can continue operating while maintenance work is performed on the other.

Space-Efficient

The storage locations in the rack are designed to accommodate both aging and charging/discharging modules, enabling their functions to be changed according to production needs.

For normal aging, WIPs are stored in a double deep configuration, with a back and front storage spot at each location, to maximize storage capacity.

Fire Extinguisher

When abnormal heat or smoke is detected from a WIP, a stacker crane transports it to the fire extinguisher location where it is sprayed with CO2. To prevent unnecessary extinguishing, an additional thermal camera and web camera check can be performed prior to spraying. Once sprayed, the stacker crane transports the WIP to a water tank at the end of the aisle.

Easy Expansion

System expansion, the addition of new aisles next to the existing system, can be achieved with little interruption to the existing system operation.

Additionally, Daifuku's rail-guided vehicle system comprising Sorting Transfer Vehicles (STVs), can be added to connect and integrate aisles into a single production system.

Contact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact UsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact Us