Supply Chain Management

Daifuku Group Procurement Policy

Basic Approach

The Daifuku Group will contribute to the creation of a sustainable society by engaging in sound business practices in accordance with our company creed, management philosophy, and Group Code of Conduct. In procurement, we shall select business partners based on appropriate criteria, comprehensively evaluating quality, technological development capabilities, economic rationality in terms of price and delivery time, as well as the status of environmental and social initiatives. We shall also require all our business partners engaged in the production, installation, and services for our Group’s products to understand and practice the Sustainable Procurement Guidelines that we have established separately, and we shall work together with our stakeholders to build a sustainable supply chain.

Basic Policy

We will ensure that all Group officers and employees are aware of this policy and promote responsible procurement.

- Compliance with laws and regulations

- We will comply with the laws, regulations, international codes of conduct, and other social rules of the countries and regions where we conduct business. We will stand firmly against antisocial forces or organizations that are a threat to the order and safety of civil society, and we will not have any relationship with them.

- Fair and equitable trade

- We will open our doors to a wide range of domestic and international companies, regardless of the country in which they are located or their size, to provide opportunities for free competition. We will conduct transactions through fair and equitable procedures, and we will eliminate misconduct such as the offering or receiving of inappropriate benefits.

- Building partnerships

- We will respect all business partners as equal partners and build long-term relationships of trust based on mutual understanding. We will commit to solving environmental and social issues in the supply chain by strengthening communication and collaboration to achieve mutual sustainable growth.

- Pursuing quality and safety

- We will pursue quality and safety in the products and services we procure. We will require our business partners to comply with the applicable laws, regulations, and standards of each country and region with respect to quality and safety, and we will provide guidance and support as needed to help them establish systems and management structures to achieve this.

- Respecting human rights

- We will respect the fundamental human rights of all people involved in the products and services we procure, and we will not be complicit in any human rights violations, including forced or compulsory labor, child labor, discrimination, abuse, and harassment. We will also give due consideration to the working environment and health and safety of our business partners. If it becomes evident that the Group’s procurement activities have caused or contributed to an adverse impact on human rights, we will strive to take appropriate and effective remedial measures.

- Responsible sourcing of minerals

- We will not procure minerals such as tin, tantalum, tungsten, and gold that are mined in conflict-affected and high-risk areas (CAHRAs) and may involve corrupt activities, support for armed groups, human rights violations, environmental destruction, or other adverse activity. We will also request our business partners to not use conflict minerals and will work to establish a management system for this.

- Reducing environmental impact

- We will comply with laws, regulations, and agreements related to environmental conservation, and we will give priority to the procurement of products and services with a lower environmental impact. We will provide guidance and support to our business partners as needed, and we will address environmental issues such as climate change and biodiversity conservation throughout our supply chain.

- Information security and protection of intellectual property rights

- We will establish a management system and appropriately manage and protect confidential and personal information obtained through our business activities. We will also respect the intellectual property rights of third parties and business partners, and we will not violate them.

- Formulation of a business continuity plan

- We will work to identify and assess risks that will have a significant impact on business continuity and formulate a business continuity plan (BCP) in preparation for large-scale natural disasters and unforeseen circumstances. In order to fulfill our supply responsibilities to customers, we will implement measures in cooperation with our business partners as needed.

- Information disclosure and communication

- We will disclose the status of our initiatives based on this policy in a timely and appropriate manner and communicate with our stakeholders.

Established: January 31, 2024

Sustainable Procurement Guidelines

In fiscal 2023, the Daifuku Group formulated the Sustainable Procurement Guidelines as a new standard for sustainable procurement activities. These guidelines are a complete revision of the CSR Procurement Standards, established in 2017, to promote further initiatives throughout the entire supply chain to solve a variety of social issues. We are striving to disseminate these guidelines throughout the entire supply chain and strengthen initiatives to identify and mitigate risks in the supply chain and with our business partners.

Our specific efforts include distributing videos explaining the Group’s sustainable procurement goals as well as obtaining agreement from all business partners (80% agreement rate as of July 2025). In addition, we request that our business partners complete a self-assessment questionnaire (SAQ) to confirm their compliance with our guidelines (the SAQ confirms the status of compliance with laws and regulations, labor standards, health and safety, quality and safety, the environment, information security, business continuity plans, and appropriate information disclosure). In fiscal 2024, based on the results of the SAQ we conducted a trial visit to one domestic supplier, during which we confirmed the status of their compliance and thoroughly examined methods of correction. Furthermore, we visited four global Group companies (South Korea, Taiwan) to conduct factual investigations and discuss the schedule for SAQ implementation as well as various issues. In fiscal 2025, we will expand the scope of the SAQ, and we are planning proactive audit visits.

For more information on the Sustainable Procurement Guidelines, please refer to the PDFs below (available in six languages).

- English (PDF: 388KB)

- Japanese/日本語 (PDF: 1.6MB)

- Simplified Chinese/簡体中文 (PDF: 546KB)

- Traditional Chinese/繁体中文 (PDF: 934KB)

- Korean/한국어 (PDF : 850KB)

- Thai/ไทย (PDF : 463KB)

Green procurement

The Daifuku Group has formulated the Green Procurement Guidelines, which denote the evaluation standards for any chemical substances that are contained in our products. In recent years, regulations regarding the management of hazardous chemical substances have been tightened, and in order to respond to growing demand, these guidelines were revised in 2023. These guidelines apply to all products (materials, parts, units, accessories, and packaging materials) and services procured by the Daifuku Group. Our policy is to prioritize the procurement of products that contain minimal hazardous substances of concern and products that contain minimal hazardous substances throughout the product’s life cycle. We are working with our business partners to reduce environmental impact throughout our entire supply chain. Furthermore, for our major business partners, we request that they fully understand the Guidelines, and in order to promote the appropriate management of chemical substances, we ask that they submit proof of receipt and written informed consent (submission rate: 97%).

Declaration of Partnership Building

The Group will continue its efforts to comply with the contents of the Declaration of Partnership Building in order to create new partnerships by promoting cooperation and coexistence with business partners in the supply chain and other value-creating entities.

Declaration of Partnership Building (Japanese only) (PDF: 440KB)

Action for fair and transparent transactions

In order to build fair and impartial relationships with business partners and conduct transactions in accordance with healthy business practices, we have established internal rules that prohibit officers and employees, in principle, from receiving entertainment, gifts, or other personal benefits or conveniences from business partners.

Promotion System

The Production Innovation Division was established in fiscal 2023 to oversee and manage risks in the supply chain. From fiscal 2024, the Supply Chain Management Committee began its operations with the CPO (Chief Production Officer) acting as leader and representatives from all business units across the company in attendance. This committee is working on a variety of initiatives to promote sustainable procurement activities and optimize the supply chain, as well as enhance credit management systems and ensure compliance in production and installation operations.

Major Initiatives

Procurement Worker Qualification Course System

The Procurement Worker Qualification Course System, which primarily targets employees involved in procurement-related work, is an e-learning course held several times each year to allow employees to gain a compliance mindset and knowledge of the relevant laws and regulations necessary for ordering work, such as production and procurement, with the aim of engaging in ordering work with integrity and high ethical and moral standards in line with our management philosophy and the Group’s Code of Conduct. Employees obtain qualification by passing a confirmation test after taking the course.

Engagement with suppliers

Management and Safety Policy and Production Trends Presentation

Daifuku hosts the Management and Safety Policy and Production Trends Presentation to which we invite our major business partners, from manufacturers and trading companies to processing, installation, service, design, and software development. This event is held to report on production trends and safety and health initiatives in each of the Group's business divisions as well as to request cooperation in addressing environmental and social issues throughout the Group’s supply chain. 291 business partners were invited in fiscal 2025.

- Supplier Quality Development (S.Q.D.) Award

- In fiscal 2003, we established the Supplier Evaluation System, and each year we present the S.Q.D. Award to commend outstanding materials (production outsourcing and goods purchasing), design, and installation contractors. In fiscal 2025, six out of 235 eligible companies selected from across all of our business partners received this award at the Management and Safety Policy and Production Trends Presentation. The candidates were evaluated based on quality and environmental criteria, and we support our suppliers’ development by sharing the best practices of the award-winning companies.

| Award category | Recipient suppliers |

|---|---|

| Quality Excellence Award | Tokai Denki Co., Ltd. |

| Quality Commitment Award | Handen Co., Ltd. |

| Nisshin Sango Co., Ltd. | |

| Sanwa Es Co., Ltd. | |

| Toa Musendenki Co., Ltd. | |

| Environmental Excellence Award | Daiichi Co., Ltd. |

FY2025 S.Q.D. Award Recipients

Informing suppliers of our policies

To ensure that our stakeholders around the world, including our suppliers, are fully aware of our policies regarding sustainable procurement, we have published the Group Code of Conduct, the Daifuku Group Human Rights Policy, the Basic Procurement Policy, the Sustainable Procurement Guidelines, and the Green Procurement Guidelines on our website. After the Daifuku Group Human Rights Policy was formulated in 2021, the CEO has been working to promote understanding and implementation of the policy by inviting major suppliers to our Management and Safety Policy and Production Trends Presentation.

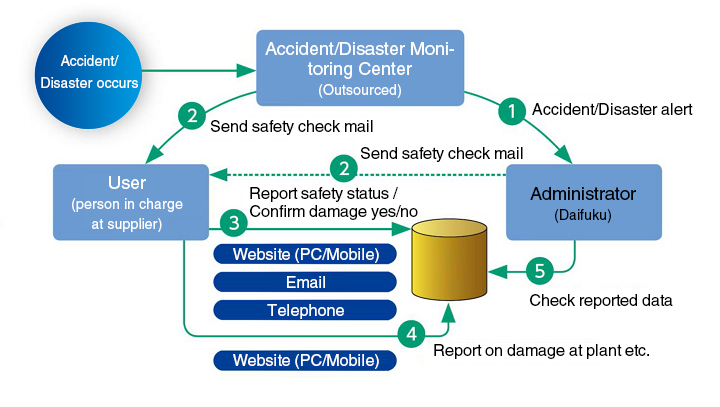

Supplier Operations Verification System

Please enlarge the screen to view

To ensure stable procurement of parts and other supplies in the event of a disaster, we have introduced a Supplier Operation Verification System that enables rapid collection of information on damage to suppliers. In an emergency, this system confirms the status of damage to suppliers and safety of personnel by e-mail, which allows for timely restoration and return to normal business operations for the entire supply chain. Periodic training is conducted with suppliers to bolster operational proficiency, and in the event of an emergency, the system is used to confirm the viability of operations and the delivery date of parts.