Case Picking Robot / Robot Palletizer / Robot Depalletizer

The robot picks the ordered quantity in case units and stacks them on a shipping pallet. Compared to manual picking and stacking, this system can reduce the variation in load form and create a stable load condition for shipment. Each unit can process up to 600 cases per hour, freeing up about three valuable human resources from monotonous work.

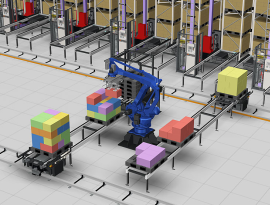

Automatic palletizing from an inventory pallet to a shipping pallet

The robot picks products from inventory pallets and palletize onto a shipping pallet to make an order pallet. If the stacking order on the pallet is specified, the inventory pallets are fed from the automated warehouse to the robot position in the specified sequence. The optimal stacking pattern is calculated by the simulator, making it possible to create stable shipping forms.

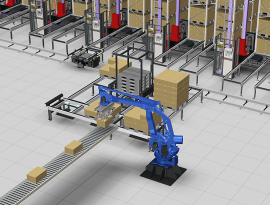

Picking from an inventory pallet to a conveyor

The robot picks the quantity instructed by the computer in case units and puts them on the conveyor. After picking the required quantity, the inventory pallets are re-stored in the automated warehouse.

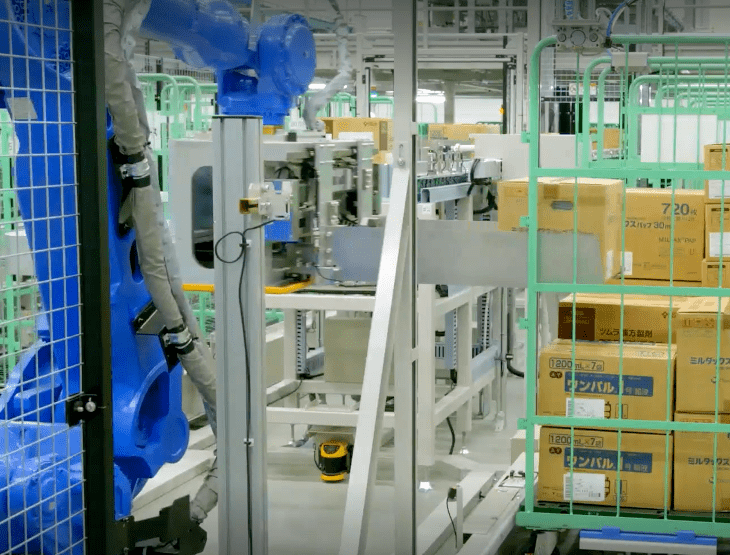

Automatic loading to a roll box pallet

The robot automatically loads cartons, which have been sequenced and sorted in advance by destination, into a roll box pallet. The simulator automatically calculates the optimal stacking pattern, making the mix palletizing process fully automatic.

Application Examples

- *The above system is provided as a part of the automation system. Please note that we do not sell the robot by itself.

Contact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact UsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact Us