Trusco Nakayama

Strengthening immediate delivery capabilities of 400,000 SKUs

Trusco Nakayama is a B2B wholesaler that purchases professional tools from manufacturers and distributes them to machine tool dealers, online shopping companies, and home centers, supplying professional tools to manufacturing sites throughout Japan. The number of items in stock at Trusco Nakayama is the largest in the industry, and the company maintains a high-level immediate delivery system.

In 2020, the company launched Planet South Kanto, which focuses on three key objectives: strengthening immediate delivery capabilities, solving business process issues, and improving the working environment.

Solution

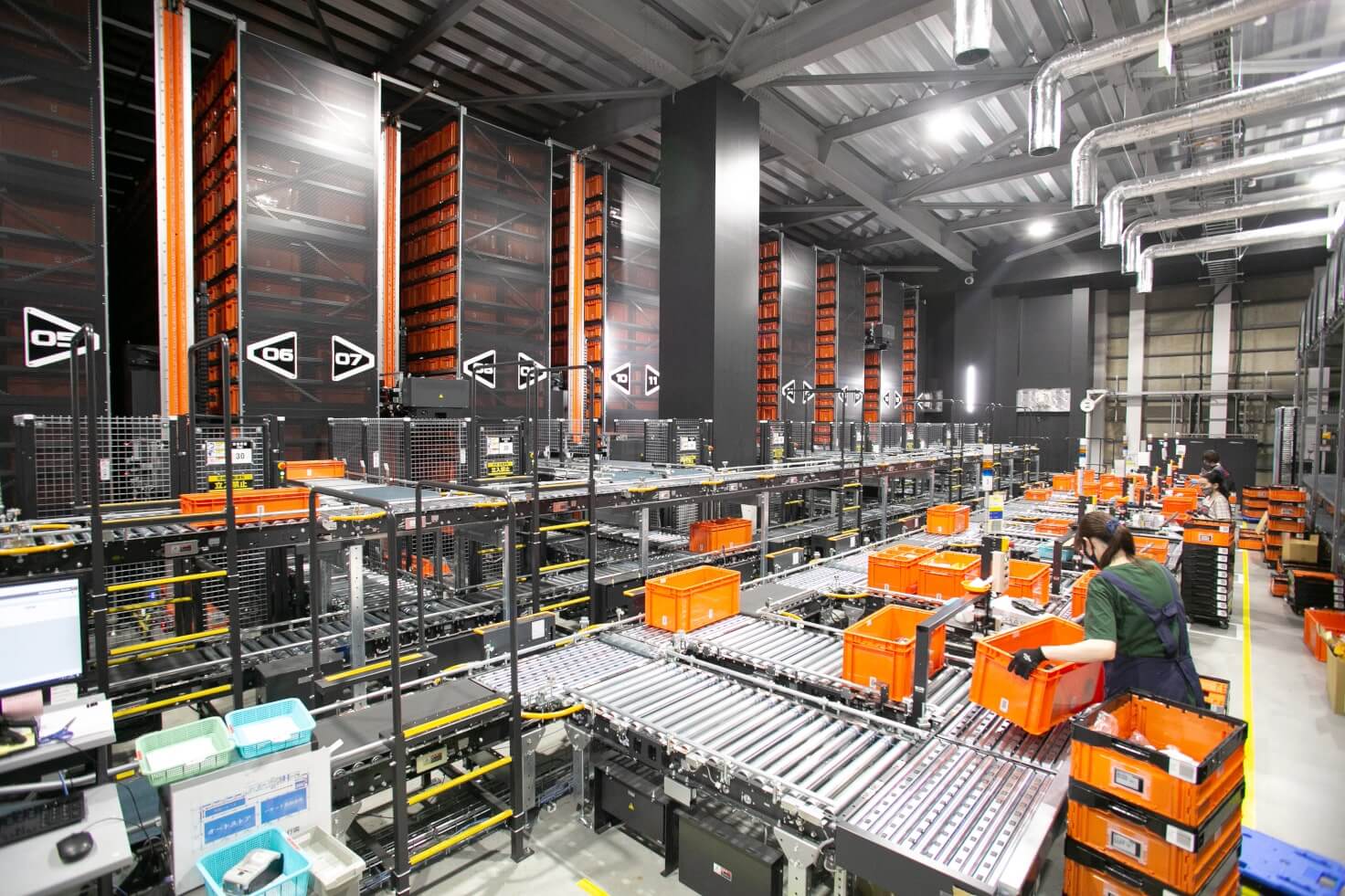

Goods arriving from tool manufacturers are inspected and small items are sorted using the put-to-light Digital Assort System, and then stored in the mini load AS/RS or conventional racks. Small items are batch picked regardless of logistics channel. The picked products are then sorted by order line and stored in the multi-shuttle system Shuttle Rack M. They are then merged by order at order consolidation stations, stored back into the Shuttle Rack M temporarily, and then retrieved by logistics channel. Products to be delivered by a courier company are then packed, while the rest of the orders are shipped in collapsible containers, together with the larger items.

A particularly significant innovation was the picking operation. Trusco Nakayama has 10 different logistics channels, including its own delivery service, third-party transport services, user direct delivery from manufacturers, inter-site transport, and returns.

In the past, when orders for the same product were placed for different logistics channels, the picking operators had to pick by each channel. Consequently, they had to walk the same route many times a day.

Batch picking of products regardless of final transport types

Sorting batch-picked items by order lines

Shuttle Rack M stores both totes with items sorted by order line and totes with items consolidated by order

At six order preparation stations, the items sorted by order line are combined according to destination

The company has also automated its location management, which was previously done manually. The size of the product, stock quantity, shipping frequency, shelf space and bucket volume are registered into the database in advance. When the goods arrive, the data is cross-checked and the system automatically indicates the most suitable storage location. This allows for high-density storage as well as inventory management based on shipment frequency, which contributes to improved workability.

Result

A major challenge is how to manage the products and workers in this large facility and how to improve operational efficiency. The use of a material handling system and the improvement of operational processes has led to the solution of a number of issues.

Our preliminary estimates were for a 16% increase in productivity. Since we started to operate the system, we have seen even greater benefits than that in practice - it fits our business perfectly. This batch picking system is now being rolled out to our distribution centers across the country.

Hideki Naoyoshi

Director and General Manager, Logistics Division

Contact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact UsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact Us