Non-Contact Power Supply Transport System Technology

In 1993, Daifuku developed the world's first monorail system that utilized a non-contact power supply*, which has garnered attention as the next-generation transport system to create a clean environment. The system supplies electric power to moving objects without coming into contact with them. The first system was delivered to the Iwate Plant of Kanto Auto Works, Ltd. in 1993 (photo). Since then, Daifuku's non-contact power supply transport systems have been expanding from the automobile industry to other industries, including semiconductors, food, and pharmaceuticals.

- *The noncontact power supply system was named HID, an acronym from High Efficiency Inductive Power Distribution Technology.

A Brief History of Development

The elementary technology of HID was invented in 1990 by a group of researchers at the University of Auckland, New Zealand, led by Professor John Boys. Daifuku conducted research and development jointly with the university and successfully put HID technology into practical use. Our HID technology solved drawbacks of the conventional contact power supply technology using trolley lines and collectors, including collector wear, wear debris, and sparks generated by line separation. Daifuku signed a technical license agreement with the University of Auckland and has the exclusive rights to the use and sale of HID in the material handling market. At present, the HID technology is patented in many countries.

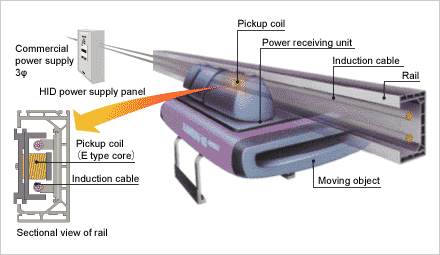

Configuration and the Roles of Components of HID system

The HID system consists of the following four components.

- HID Power Supply Panel

- The power supply panel converts the commercial power supply to a frequency suited to noncontact power supply and feeds electric power to the induction cable.

- Induction Cable

- The induction cable is a special electric line installed along the rail of a moving object. A magnetic field is generated around the cable in order to efficiently transmit electric power to a moving object.

- Pickup Coil

- The pickup coil is installed on the side of the moving object opposite the induction cable and receives electric power from the magnetic field around the induction cable.

- Power Receiving Unit

- The power receiving stabilizes electric power that the pickup coil receives and feeds quality electric power to inverters and servo drivers.

Features of the HID System

Features

The features of the HID system are that the induction cable and the pickup coil are non-contact and that the induction cable is covered by insulating material. It has the following benefits.

(1) High reliability and durability

Collectors for non-contact power supply require a refined 3D mechanism in order to achieve stable contact. The HID has a simple structure and its noncontact configuration allows stable electric power supply for an extended period of time.

(2) Maintenance-free

Conventional collectors may be increasingly worn out depending on the surrounding environment. Since the HID is non-contact, its collectors and trolley lines never become worn, and thus significantly reducing maintenance costs.

(3) Applicable to clean environments

The system never generates dust that contact collectors often produce. It is therefore indispensable for environments where no dust is allowed, such as clean rooms.

(4) Applicable to environments where oil mist and/or water vapor occurs

Contact power supply may not always be used in places where dust, oil mist, and/or water vapor occur. HID systems can be used in such places without problems.

(5) Safe power supply system

The power supply cable is entirely insulated and has no exposed parts, so there is no risk of electric shock. Electric power is supplied to the moving object by electromagnetic coupling and electric sparks will not be generated, making this is a very safe power supply system.

Conclusion

The HID system is widely used in the automobile, semiconductor, and flat panel display manufacturing industries. In short, what many users want from their facilities is high availability. Specifically, this means that maintenance is unnecessary or minimal, only a short time is needed to change the facility’s layout, errors and breakdowns do not occur, and recovery from problems is very quick. We anticipate that our HID system will be used extensively in many industries as important support technology to meet these requirements.

Related links

Wireless Power Supply SolutionsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact UsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact Us