Charoen Pokphand Foods

Thailand’s first cold storage AS/RS is establishing a high-quality cold chain system

In June 2014, Charoen Pokphand Foods Public Company Limited (CP Foods) – headquartered in Bangkok, and the core company of Thailand’s largest conglomerate, CP Group – built a new distribution center in the Bang Nam Prieo district, located in the east of Bangkok. This distribution center handles all of the company’s products and improves storage quality and inventory management – as well as labor-saving– through the combination of the country’s first cold storage AS/RS, Sorting Transfer Vehicles (STV), and Digital Assort System (DAS).

Challenge

CP Foods has established a value chain from the upstream to the downstream of the food industry, from livestock feed to stock breeding, fisheries, processed foods, and retail. In recent years, CP Foods’sales have made up approximately 30% of CP Groups’ entire sales volume of approximately 40 billion dollars (4 trillion 800 billion yen) and CP Foods has been expanding its business in seventeen countries and regions, including Russia and other Asian countries.

Previously, CP Foods stored and managed its products at four different factories in Thailand. As recent demands increased, CP Foods leased commercial warehouses due to limited storage space at its factories. This resulted in issues, such as a decline in the quality of inventory management and a rise in distribution costs.

In order to address these challenges and to optimize the entire supply chain of the company, CP Foods established a new distribution center. By consolidating distribution functions, distribution operations are now streamlined, and the center can handle high-frequency and small-lot deliveries for retailers. In addition to supplying products to mass retailers, the center also delivers to small-scale food stores. These include CP Foods’ own CP Fresh Mart, which it opened in 2006, as well as many new Seven Eleven convenience store locations that are managed by CP ALL.

Solution

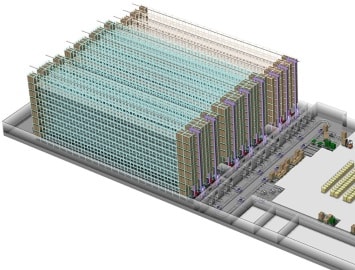

The new distribution center achieved high-density storage by introducing a 21 m high AS/RS. In addition to storage capacity increasing five-fold, inventory management, first-in-first-out and product freshness are consistent throughout the facility. The AS/RS is partitioned into two areas, the frozen area (−25℃ / 13° F) and the chilled area. The AS/RS has eight cranes and 10,700 pallet locations in total and is connected with the loop-type (10 units) and dual-type STV.

Upon retrieval from the AS/RS, case shipping items are transported by the loop-type STV to the picking station and picked by case. Small order items are transported by the dual-type STV, picked by case, and then fed into the Put-to-Light system "DAS" for piece picking. The new distribution center significantly improves work efficiency and labor-saving. As CP Foods’ largest distribution center, it now ships up to 12,000 cases per day. The center has enhanced its distribution capabilities while building a higher-quality cold chain system.

Transferring products to and from the ASRS, dual type-STVs, and shipping area, are automated via the loop type-STVs.

Picking stations. Products are picked by case and stacked on a pallet for shipping, according to orders.

The AS/RS in the frozen area, with five double-deep-type S/R machines. The AS/RS in the chilled room has three single-deep-type S/R machines.

Customer's Voice

Danai Galassi, Supply Chain & Logistic Management Senior Vice President

We chose Daifuku out of many material handling companies due to their comprehensive support structure. Moreover, they have business operations in the same areas as us, and they understand the conditions of the food industry in Asia, allowing us to trust in them as our partner. The AS/RS improved storage efficiency and temperature control, and saved floor space and energy

Contact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact UsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact Us