The Mini Load AS/RS in a Mobile-First World

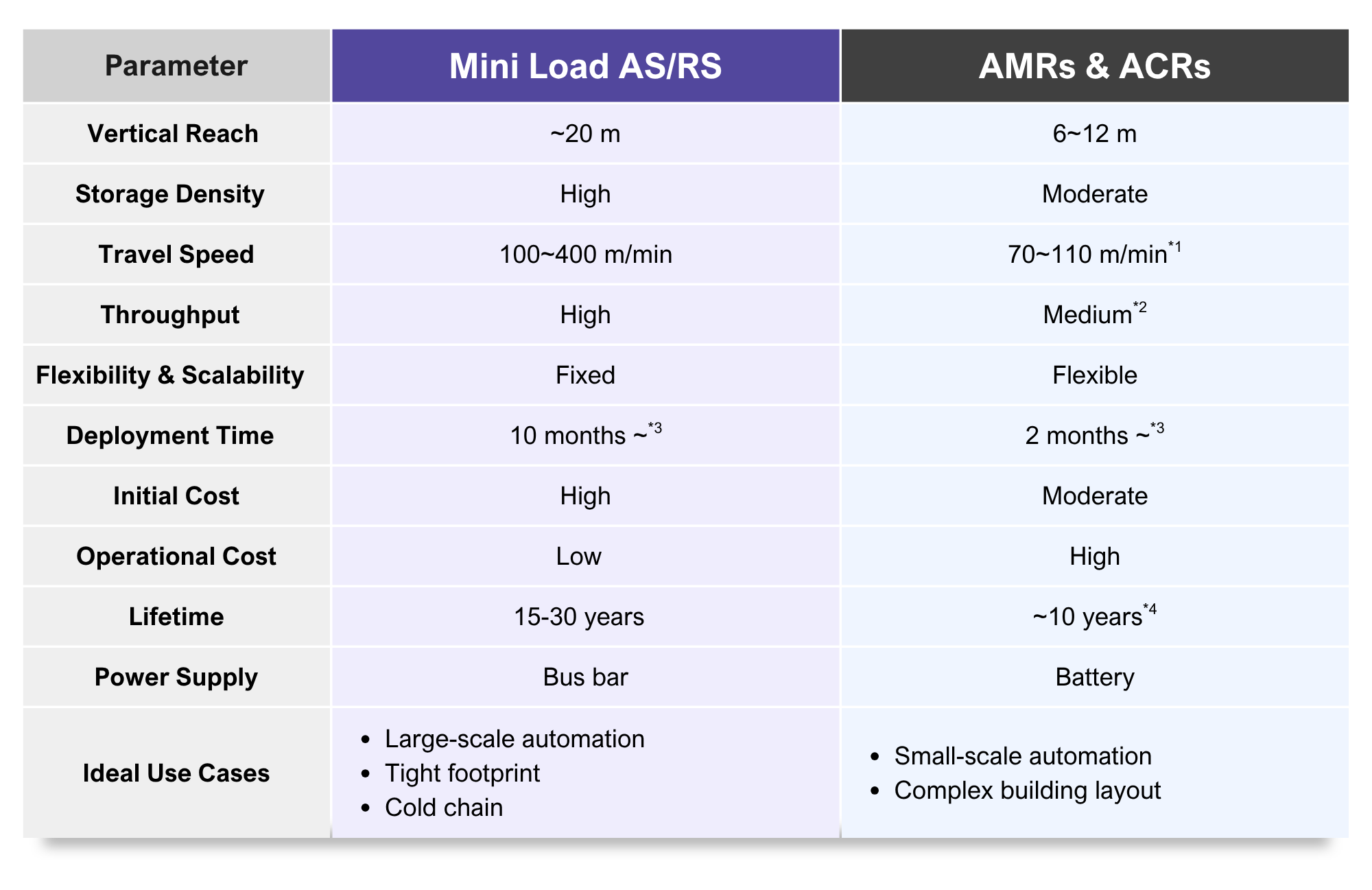

You’ve probably heard the modern warehouse battle cry: “No conveyors, no fixed equipment, everything mobile!” Autonomous mobile robots (AMRs) and Autonomous case robots (ACRs) are having their moment, and for good reason—they’re flexible, scalable, and relatively low-cost as an entry point into automation. But in all the excitement, dismissing the Mini Load AS/RS as yesterday’s technology, something to be replaced by swarms of robots buzzing around the warehouse floor, is a bit hasty. The Mini Load AS/RS still addresses challenges that AMRs and ACRs can’t. Often faster, more reliable, and easier to operate over the long term, it’s worth reconsidering before crossing it off your list.

When Height and Density Matter

One key advantage of a Mini Load AS/RS is its vertical reach. While ACRs typically reach 8-12 meters, a Mini Load stacker crane can reach up to 20 meters—nearly double the vertical storage capacity. This is especially valuable when floor space is limited or costly.

Rather than expanding your building or relocating, building upward allows you to store more items within the same footprint. Vertical and floor space are inseparable, and a Mini Load AS/RS makes vertical storage efficient.

With double-deep storage, Mini Load AS/RSs can store more items in less space while maintaining fast retrieval. While some ACRs support double-deep configurations, they tend to be slower when accessing rear items. In contrast, Mini Load systems consistently and quickly reach deep storage locations.

When Speed and Throughput Matter

Throughput depends on speed. With mobile robots, you need a fleet. But a warehouse full of robots isn’t exactly “open space” anymore. It quickly becomes crowded, making traffic management a real challenge. Ironically, keeping pace with fixed cranes can create congested aisles and complex traffic.

In contrast, a Mini Load operates on a rail within a controlled aisle, achieving high cycle rates without the chaos. For operations that demand speed, like feeding production lines or clearing finished goods, fulfilling orders, or replenishing picking rows, this advantage really adds up.

Testing the Waters

AMRs and ACRs are exciting because they’re easy to deploy. For companies new to automation, starting with mobile robots is a low-risk, fast way to get started. But as operations scale and space becomes constrained, upgrading to a fixed system like a Mini Load AS/RS often makes sense. In this way, mobile systems can serve as a steppingstone toward a longer-term automation strategy: high storage density, vertical utilization, speed, and long-term reliability.

Power Plays: Batteries vs. the Bus Bar

Mobile robots rely on lithium-ion batteries, requiring charging infrastructure, battery swaps, replacements, and eventually new packs as the old ones wear out. It’s a behind-the-scenes headache that grows during peak operations (*1). A Mini Load system? Just power it on. No charging cycles, no battery logistics, no mid-shift power concerns. Just a continuous flow of electricity from the bus bar.

Applications Where the Mini Load AS/RS Shines

Manufacturing

Beyond automotive, electronics, and pharmaceuticals, Mini Load AS/RSs play a vital role in a wide range of factories, managing parts storage, WIPs and QC buffers, tools and jigs, and finished goods before picking or palletizing.

At Komatsu, the Mini Load AS/RS helps deliver raw materials to multiple factories within a production site

At Connectwell Industries, the Mini Load AS/RS handles raw materials, WIP, and finished goods.

At Panasonic Energy, the Mini Load AS/RS buffers finished products for the packing line.

Distribution

In distribution sectors, the Mini Load AS/RS serves as a buffer for order picking and aisle replenishment. In cold storage facilities, they help keep workers out of freezing environments, optimize costly space and outperform battery-powered vehicles, which are less efficient in the cold. Apparel and FMCG operations also benefit, storing dense bins or cases for rapid retrieval and continuous flow.

Automotive: Spare parts storage at the service parts center

Machinery: Product storage at a distribution center

Stationery and Office Supplies:Picking Replenishment Buffer

Cold Chain: Piece picking buffer of frozen food.

Apparel and footwear: B2B and B2C order fulfillment buffer.

Hospital: Stores sterilized surgical tool containers

Choosing the Right Mix: Mini Load AS/RSs and Mobile Robots

That’s not to say robots are pointless. They’re flexible, quick to deploy, ideal for dynamic layouts, and allow companies to start small with minimal risk. But they’re not a one-size-fits-all solution. The notion that fixed systems are obsolete is more hype than reality.

In practice, the smartest facilities often deploy a hybrid approach: robots in places where flexibility matters most, and a Mini Load AS/RS where density, vertical space, and speed are critical. A balanced, well-informed automation strategy blends strengths of both. And in that mix, the Mini load continues to play a vital and thoroughly modern role.

The warehouse of the future isn’t about chasing the latest tech trend, it’s about choosing solutions that best support long-term workflows. The right tools need to be in the right places. And for many operations, the Mini Load AS/RS remains one of the most reliable and efficient options available, especially when reliability, density, throughput, and energy efficiency are essential.

Please enlarge the screen to view

- *1: Daifuku's research on volume zones of key ACR suppliers.

- *2: Dependent on fleet size and traffic management.

- *3: Vary by system size.

- *4: Based on Daifuku’s market survey; not yet fully validated as ACR technology is under 10 years old.

Summing It Up

Next time someone says Mini Load systems are outdated, it’s worth asking: are they really? The technology may not be flashy, but it solves real problems that fleets of mobile robots still struggle with: vertical reach, storage density, throughput, and power reliability.

Add in its proven track record in industries where precision and speed are non-negotiable, and the case for keeping the Mini Load AS/RS on the table becomes clear. AMRs and ACRs may be in the spotlight for good reasons, but this does not mean that Mini Load systems have left the stage—they haven’t. Ignoring it means overlooking a proven, efficient solution that still powers critical operations in warehouses around the world.

Andrey Kras

Intralogistics Division, Daifuku

Born and raised in Russia, Andrey was educated in Japan and earned a PhD from Waseda University in 2008. After several years as a business consultant, he joined Daifuku in January 2012 as a sales manager. His responsibilities include warehousing and intralogistics consulting as well as marketing.