Sengkang General Hospital

The Future of Healthcare Intralogistics

Sengkang General Hospital (SKH) is one of Singapore’s key public hospitals, delivering comprehensive acute and specialist care. A critical function supporting its surgical departments is the Central Sterile Supply Unit (CSSU), which manages the preparation, safekeeping, and circulation of surgical instruments throughout the facility.

As part of its commitment to delivering the highest standard of patient care through the latest technologies, the hospital sought to strengthen its internal logistics framework to sustain high safety standards while improving operational efficiency in the handling of sterile instruments.

Challenges

Before automation was introduced, CSSU operations depended largely on manual processes. This approach led to several operational constraints:

- Time-consuming searches for the correct surgical boxes, particularly while maintaining FIFO compliance

- Significant physical strain on staff due to repetitive manual handling and retrieval tasks

- Operational pressure to ensure surgical instruments reach operating rooms without delays

- Limited storage space and insufficient visibility into stock status

These issues underscored the need for a solution that could streamline workflows, enhance accuracy, and improve the working environment, without affecting the hospital operations.

Solution

To address these challenges, SKH installed an automated material handling system operated through the WareNavi inventory management system along with equipment monitoring and control software. The system functions as the central storage for sterilized surgical containers and is integrated with the hospital’s tracking platform to ensure inventory visibility and coordinated delivery to operating rooms.

System Configuration

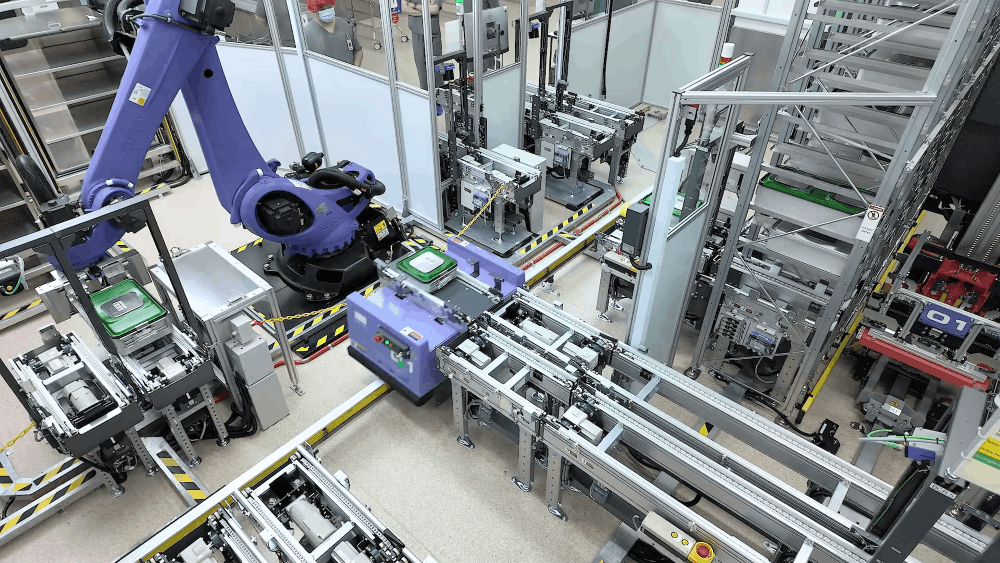

The automated material handling system comprises three independent aisles of mini-load AS/RS integrated with a mini-load shuttle Sorting Transfer Vehicle (STV), a robotic picking system.

In addition to the mini-load AS/RS, the system includes two vertical carousels dedicated to storing surgical tools with non-standard dimensions that cannot be accommodated in the primary storage. Each item is assigned to a designated bin linked to a specific carousel shelf, with all location data synchronized with the warehouse management system. This structure supports accurate inventory control and dependable access to specialized instruments, an important yet often overlooked element in surgical readiness.

Process Flow

Surgical instruments are managed through a standardized and closely monitored sequence:

- Cleaning and verification: Instruments are processed and checked following sterilization before being cleared for storage.

- Identification and tracking: Each container is assigned a barcode that records key information, including container reference and sterilization condition.

- Automated warehousing: The mini-load ASRS stores up to 2,790 sterile instrument boxes.

- Stock rotation control: A FIFO logic is applied to ensure appropriate use of sterile items in the correct order.

Integrated Control

All logistics activities are supported by the integration of the tracking system and WareNavi, which coordinate storage and retrieval while ensuring instruments are available when required. This coordinated control ensures that surgical teams receive the required instruments in line with operating schedules.

Automated Surgical Box Storage

Vertical Carousel for Odd-Sized Items

Results

The introduction of the ASRS has delivered clear operational benefits, contributing to a more efficient and people‑focused CSSU environment. Key improvements include:

- Significantly reduced retrieval times following the automated FIFO management

- Accurate inventory control and timely access enabled by WMS integration

- Reduced physical workload for staff by eliminating manual search and retrieval

- Efficient storage of both standard and odd-sized instruments through the combined use of Mini-Load AS/RS and vertical carousels

- Reliable tool availability supported by system integration between load tracking and the warehouse control system

By shifting physically demanding and repetitive tasks to the ASRS, Sengkang General Hospital allows staff to focus on what matters most—supporting clinical teams and caring for patients. Automation handles the heavy work behind the scenes, allowing people to focus on people. The result is a CSSU operation that is efficient, dependable, and clearly centered on human value and high-quality surgical care.

Discover More

Curious about what the Daifuku AS/RS can do for your operations? Explore the Mini Load AS/RS solutions to see how they can enhance efficiency and space utilization. Want to see how we’re supporting customers in Singapore? Visit our Daifuku Singapore page for local case studies, insights, and more.

Contact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact UsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact Us