Asian Bearindo

Smart Automation for Growing Demand

Asian Bearindo is one of Indonesia’s leading bearing distributors, supplying major car manufacturers and industrial clients nationwide. To keep pace with rising order volumes and SKU diversification, the company built a new distribution center in Surabaya and partnered with Daifuku to introduce an automated storage system.

The challenge was clear: efficiently managing bulk inventory alongside picking stock. Previously, operators walked long distances, searched through pallets and bins, and manually picked heavy items—a process that was slow, physically demanding, and prone to errors. At the same time, Asian Bearindo needed a reliable way to maintain accurate inventory to support its growing business.

Solution to the Challenges

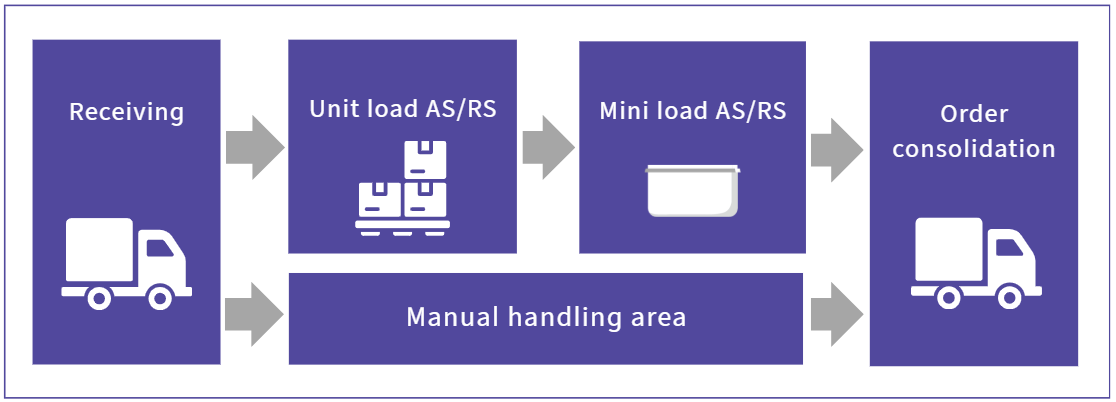

Daifuku implemented an integrated AS/RS solution to optimize material flow and order fulfillment throughout the facility. Incoming goods are first directed either to the Unit Load AS/RS or to a manual storage area. The Unit load AS/RS, consisting of two aisles and accommodating 5,600 pallets, handles bulk inventory. From there, items are case-picked from pallets at the case-picking station and transferred into the Mini Load AS/RS. This Mini Load system, with two aisles and capacity for 36,000 bins, serves as a buffer for the goods-to-person (GTP) picking stations, ensuring smooth and efficient picking operations.

The system incorporates a Mini Load STV loop and GTP picking stations, which act as key interfaces for high-speed material handling and order processing. Items picked at the GTP stations, along with those handled manually, are sent to the consolidation area, where orders are combined, checked, packed, and prepared for dispatch. All these processes are coordinated by a centralized warehouse management system, which ensures accuracy, efficiency, and seamless material flow across the entire facility.

Long-Term Business Impact

Automation has significantly improved both ergonomics and operational efficiency at Asian Bearindo’s distribution center. Manual searching and walking for picking have been minimized, allowing operators to handle heavy items safely and with far less physical strain. Replenishment, picking, and order consolidation processes are now streamlined and highly accurate, with automated and manual areas working together seamlessly.

The AS/RS solution not only enhances reliability but also supports high service levels while accommodating a growing number of SKUs. In addition to these operational benefits, the system has delivered notable improvements in ergonomics by reducing repetitive manual handling, improved inventory and picking accuracy through better stock visibility and system-controlled operations, and ensured product cleanliness by minimizing dust exposure with enclosed automated storage.

Powerful Unit Load AS/RS system engineered for 5,600-pallet storage—boosting productivity and space utilization.

Inventory totes are automatically delivered to the picking operator’s workstation for streamlined and efficient operations.

Customer's Voice

Since implementing the AS/RS, we can process more orders with fewer errors and faster turnaround times, achieving clear gains in productivity and storage efficiency. The system has been reliable and met our expectations from design through implementation, and our team adapted quickly thanks to the training provided.

Discover More

Curious about what the Daifuku AS/RS can do for your operations? Explore the Mini Load and Unit Load AS/RS solutions to see how they can enhance efficiency and space utilization. Want to see how we’re supporting customers across Indonesia? Visit our Daifuku Indonesia page for local case studies, insights, and more.

Contact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact UsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact Us