The Arnott's Group

The Arnott’s Group State-of-the-Art Distribution Facility

As one of Australia’s most iconic and beloved brands, The Arnott’s Group, has been creating delicious moments for generations with its signature biscuits and snacks for over 160 years.

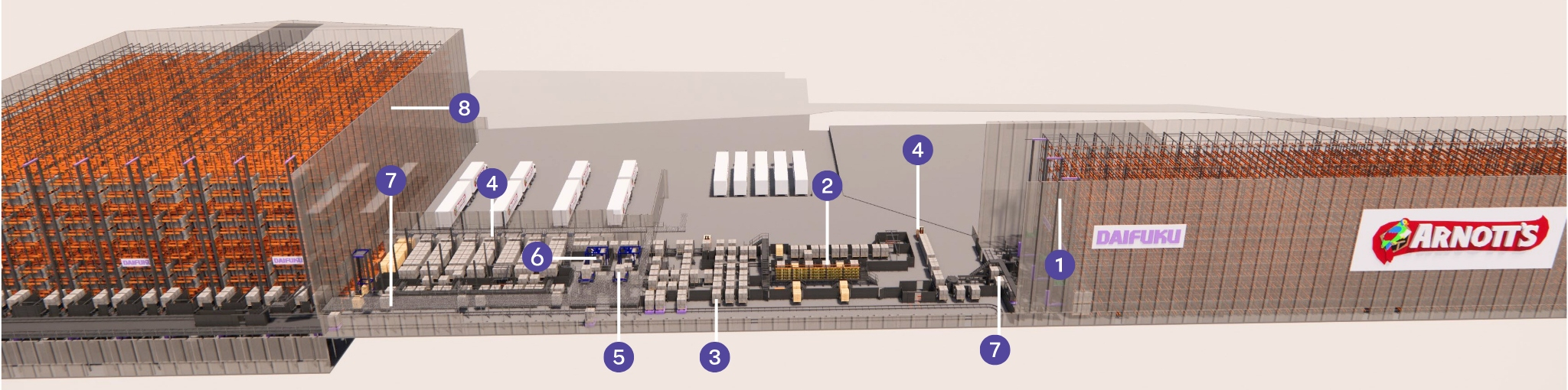

To further strengthen their logistics operations, The Arnott’s Group partnered with Daifuku to deliver a comprehensive automated material handling solution at their Huntingwood Distribution Facility. That system enables storage of up to 28,000 pallets, including approximately 5,840 in a temperature-controlled environment—2,160 of which are housed in the Supergloss AS/RS.

With 2,000 pallets distributed every 24 hours, the automated solution streamlines the entire process from manufacturing to delivery. Automation ensures products are inducted, stored, monitored, and dispatched with minimal human intervention. This one-touch philosophy enhances speed, accuracy, and visibility across operations, helping The Arnott’s Group maintain its world-class standards in food manufacturing and distribution.

System Overview

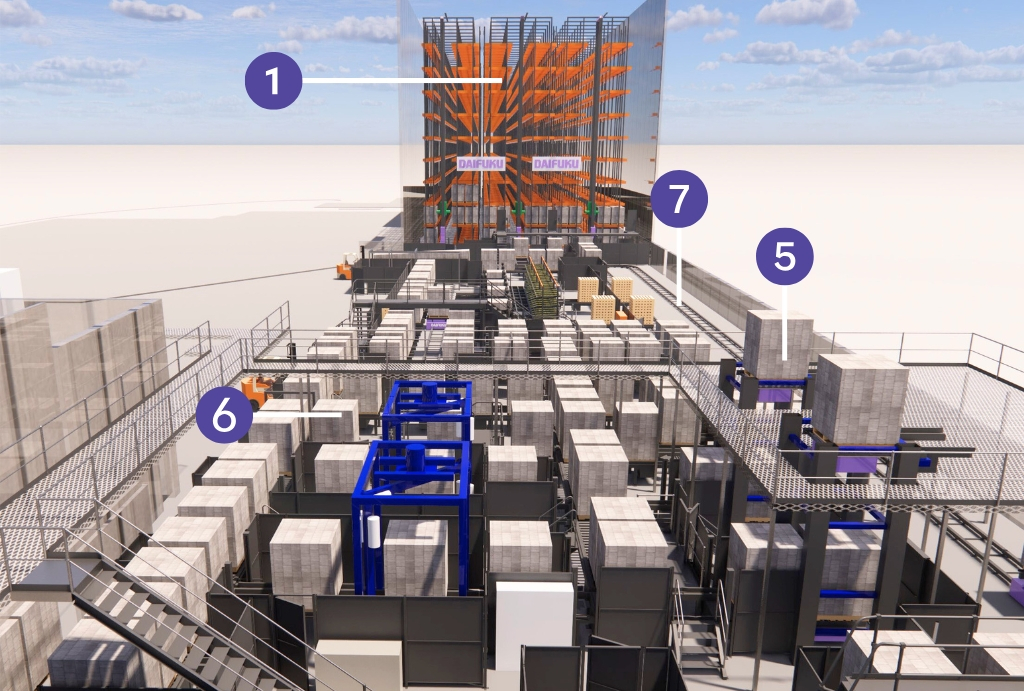

1. AS/RS Solution - 3 cranes (existing building)

The Arnott’s Group's chocolate products are stored in a 5,840-pallet Unit Load AS/RS with three cranes across two temperature-controlled chambers. Products first enter a warm chamber with one crane to achieve a Supergloss finish, then move to a cooler chamber with two cranes for further storage before distribution. Both chambers are fed by the STV.

2. Goods-to-Person Picking System (GTP)

The GTP system is where pallets are created from a mix of products. The system delivers the product to each picker in sequence based on the order and appropriate layering to ensure zero damage. Once the pick is complete, the pallet is sent to the dispatch lanes, or stored within the AS/RS system.

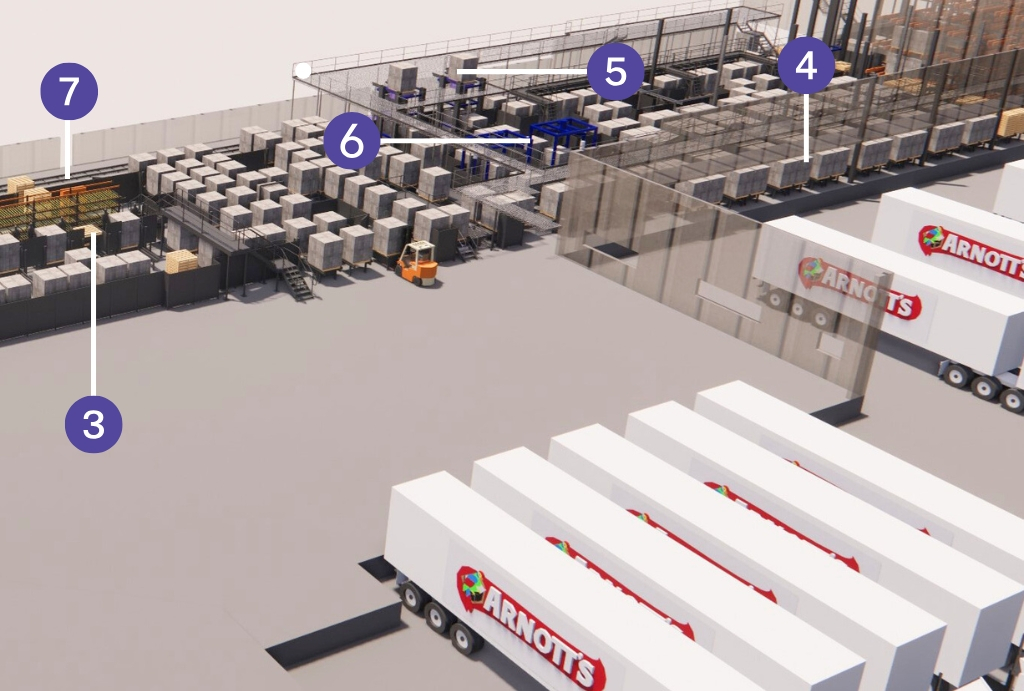

3. Order-Picking System

Completed customer pallets created in the GTP area are sent in sequence with full pallets for the same order ready for pickup and delivery.

4. Outbound Orders

In preparation for dispatch, pallets arrive at the outbound lanes in strict sequence in accordance with the product characteristics and weight to ensure no product damage during transportation.

5. Manufacturing Palletising Operations

Single SKU unwrapped pallets are transferred from the robot palletising area to the warehouse floor via elevators.

6. Wrappers

Pallets are identified, stretched wrapped and barcode labelled. After the size and product are validated they are automatically transported into one of the AS/RS high bays (1) or (8) by the STV (Sorting Transfer Vehicle) (7).

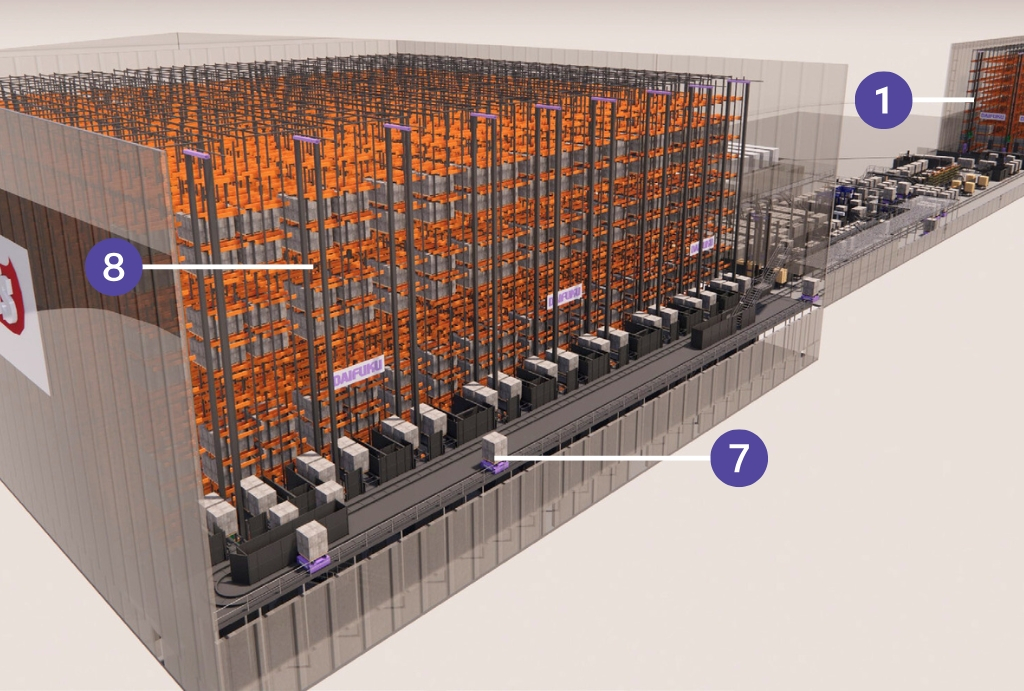

7. Sorting Transfer Vehicle (STV)

The backbone of the system, the STVs connect all aspects of the warehouse via a single rail loop capable of handling over 300 pallets per hour.

8. AS/RS (Automatic Storage & Retrieval System) - 9 cranes

The high bay system has a capacity of just under 23,000 pallets, with a throughput of 242 pallets per hour. The overall warehouse handling over 330 pallets per hour.

Technology in Operation

Outbound Orders

Sorting Transfer Vehicles

Goods-to-Person Picking System (GTP)

Customer's Voice

"Daifuku demonstrated the capability and expertise to deliver a full supply chain solution." Daniel Mesic, Warehouse & Logistics Manager, The Arnott's Group

Transform Your Operations

Discover how our Unit Load AS/RS and STVs can transform your operations, boosting efficiency and optimizing space utilization. And remember, automation doesn’t need to be large-scale to make a big impact. Explore our Unit Load AS/RS Model Systems to see how tailored solutions can meet your specific needs—because when it comes to automation, one size never fits all.

Contact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact UsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact Us