WareNavi - Warehouse Management System

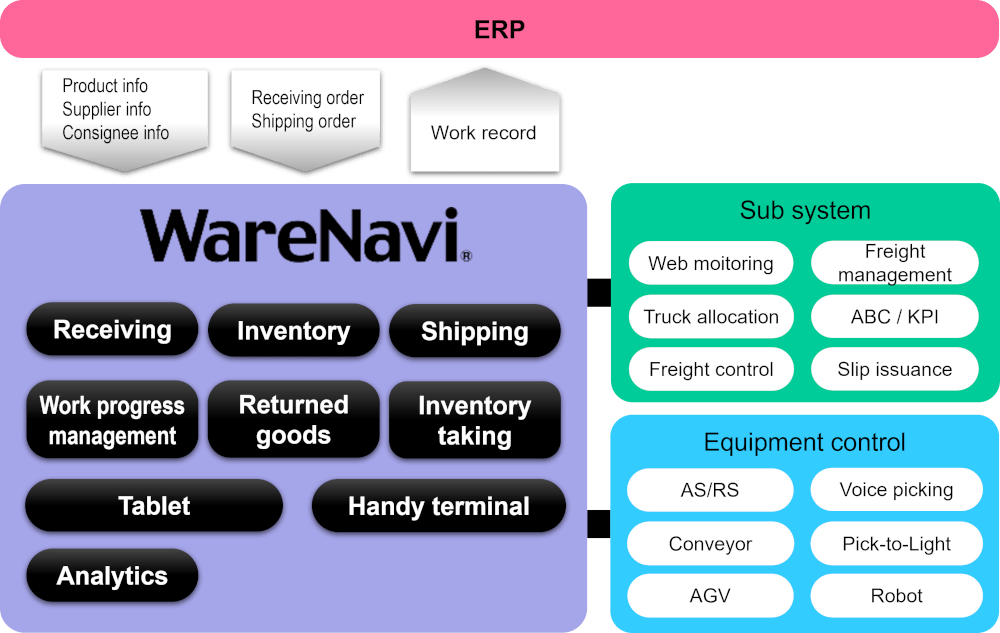

Daifuku's WareNavi is a sophisticated warehouse management system (WMS), a type of software, developed from the insights gained through over 6,000 material handling projects. It seamlessly integrates material handling system operations, task support, progress tracking, inventory oversight, and performance analytics. WareNavi enhances efficiency across distribution center operations such as receiving, storage, replenishment, picking, sorting, and shipping, offering comprehensive control and support.

Features

1. Comprehensive package

Based on a wealth of experience creating material handling systems, Daifuku’s WMS is designed to support all key processes within a distribution center, including receiving and shipping controls, inventory management, and progress management.

Capable of meeting diverse logistical needs, WareNavi can interface with an array of automated material handling equipment and warehouse operations, including AS/RSs, conveyors, sorting systems, and robots, as well as fixed racking, forklift and manually operated warehouse operations, inspection systems, and order picking systems.

2. Monitoring & analysis

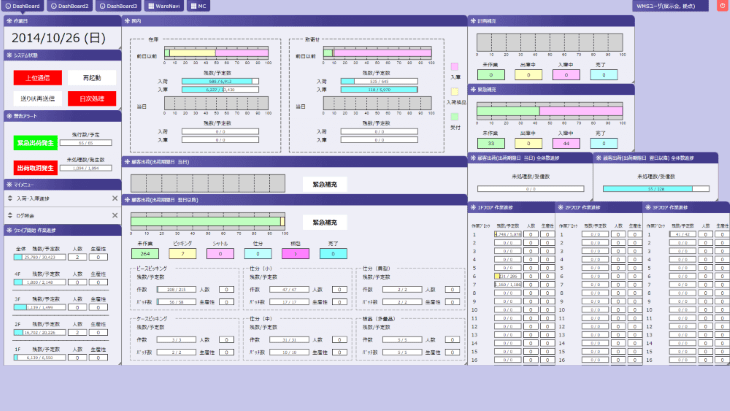

The customizable digital dashboard provides an at-a-glance view of the facility’s operation status allowing for early action in case of delays or other problems. This ensures that distribution center operations continue at maximum efficiency.

-

- Work progress monitor

- Visualizes work progress by area and operation.

- Productivity monitor

- Highlights productivity for each area and worker.

- System alerts

- Monitors and reports errors.

-

Digital dashboard

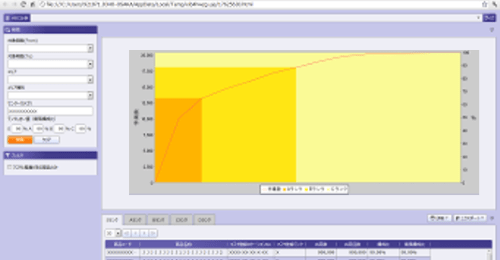

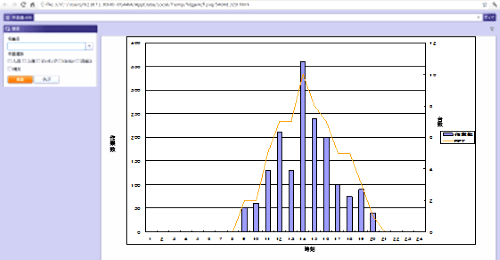

3. Business intelligence

WareNavi provides a range of analytics to improve operations, including ABC, workload, and other analyze. Exportable to CSV or Excel, gathered data assists with daily performance management, adjustments to racking layout, and worker allocation planning.

-

ABC analysis

Reviews product placement based on shipping frequency.

-

Workload analysis

Aggregates the number of operations by time period.

-

Work performance analysis

Aggregates productivity by operator or type of work.

-

Inventory turnover

Calculates inventory turnover by product.

4. Customizable parameters

Even after the system is up and running, operational parameters within the system can be manually adjusted according to on-site needs. The system can quickly adapt to changing circumstance, such as wanting to add more fixed racking or changing receiving inspection methods.

Adjustable parameters

- Facility controls

- Shipping controls

- Area, zone, and rack controls

- Label and report form controls

- Product controls

- Storage controls

- Receiving controls

- Shipping controls

5. Customizable user permissions

Menu permissions in WareNavi can be customized for each user. This ensures that only authorized menus are shown, preventing accidental access to menus that fall outside of an operator’s work scope. The program also supports login verification requirements, including IC cards, color barcodes, and biometric authentication.

Contact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact UsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact Us