InstaGuard: AI's Role in Transforming Workplace Safety in South Korea

In today's world, with increasing awareness of human rights, companies have a crucial responsibility to respect workers' rights and ensure safe and healthy working environments. Accidents at worksites can have serious consequences: life-changing injuries for the affected individuals and severe damage to a company's reputation and ability to conduct business.

In South Korea, the enforcement of the Serious Accidents Punishment Act has tightened safety regulations, demanding even more advanced measures. To address these challenges, Daifuku Korea has developed InstaGuard, a cutting-edge solution that uses AI for monitoring and equipment control to prevent workplace accidents. This innovative system is quickly gaining recognition across the country.

Understanding the Serious Accidents Punishment Act

The introduction of the Serious Accidents Punishment Act has brought significant changes to South Korea, particularly in holding management and safety officers accountable when accidents occur. Previously, the country’s labor safety laws imposed fines and business suspensions, but this new law raises the stakes with heavier criminal liabilities, including the risk of imprisonment for executives and site managers. Companies can face not only compensation and prevention costs but also invisible losses like a damaged corporate image and loss of trust from stakeholders. This has led to a heightened responsibility for companies to do their utmost to prevent accidents, ensuring the safety and well-being of their workers. While automation has boosted production efficiency, it has also increased the risk of workers being inadvertently involved in accidents when maintenance personnel enter automated equipment areas. Therefore, it is crucial for companies to implement advanced safety measures to protect their employees and create a safer work environment.

Meet InstaGuard: Your Safety Solution

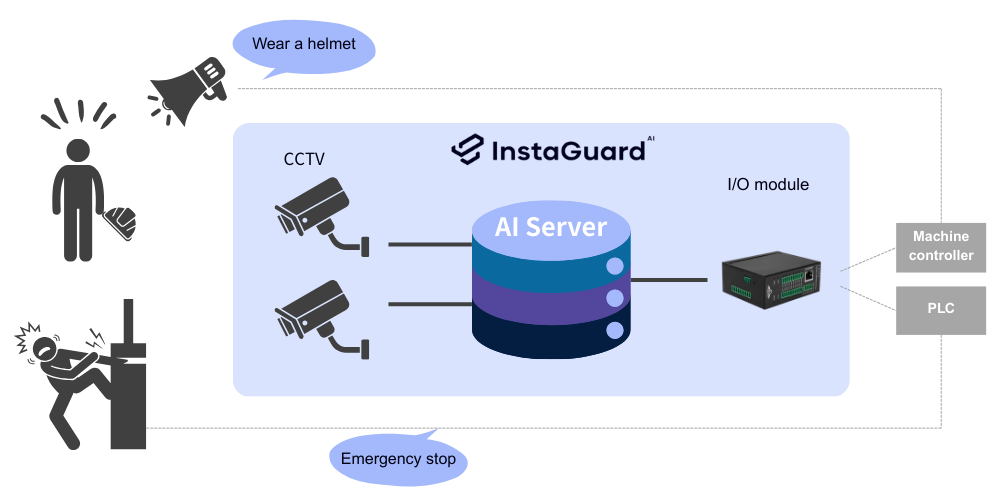

Daifuku Korea's InstaGuard uses AI and cameras to monitor sites in real-time, quickly detecting dangerous situations and controlling equipment to significantly reduce workplace accidents. This system combines live camera footage with AI analysis to monitor hazardous areas and detect worker movements and protective gear usage in real-time. Standard models can detect human entry, movement, falls, helmet usage, and fires, making it immediately beneficial for a huge number of sites. Further, the system can be adapted according to specific site requirements.

InstaGuard is available in both fixed and mobile types, allowing for constant monitoring of hazardous areas in production lines and warehouses, as well as temporary spot monitoring in construction and maintenance sites. It features a flexible interface with various control devices, enabling it to work with PLCs and robot control devices to automatically stop machinery or sound alarms. This makes it relatively easy to implement as an additional safety measure within your facility.

Please enlarge the screen to view

Real-World Applications

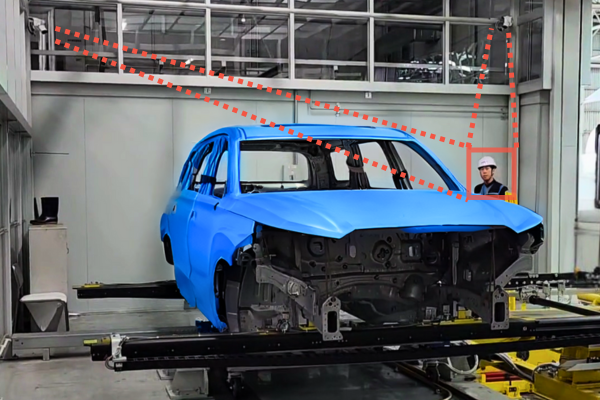

A leading South Korean automobile manufacturer has significantly improved safety on its production lines by adopting InstaGuard. The system prevents contact between workers and overhead conveyor equipment, automatically stopping machinery when operators enter hazardous zones for maintenance or inspection. Typically, access to these areas requires the deactivation of infrared sensors—a process known as light curtain muting—but InstaGuard continues to function without interruption, ensuring ongoing protection.

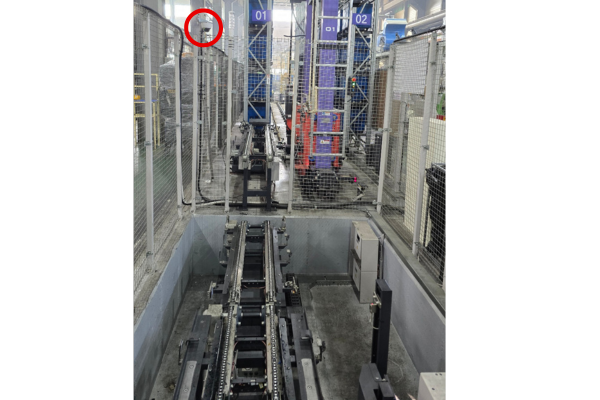

It also detects when personnel enter a pit area equipped with a lift-type infeed conveyor for an automated storage system during operation, immediately triggering alarms to prevent potential accidents.

At Daifuku Korea construction sites, the mobile version of InstaGuard plays a critical role in monitoring areas around pits before permanent safety fences are installed. By issuing alerts when there is a risk of falls, the system has dramatically reduced onsite hazards. Lightweight and easy to deploy, the mobile unit can be quickly repositioned as work progresses, offering flexible and reliable safety coverage throughout the construction phase.

-

Automobile Factory - Enhancing safety by covering blind spots

-

Machinery Manufacturer - Boosting safety at automated warehouse entry and exit points

-

Construction Sites - Improving safety in dynamic environments

The Value of InstaGuard

As highlighted, safety is a key focus for executives in South Korea. InstaGuard provides significant reassurance by ensuring worker safety and protecting corporate image and business continuity. For site managers, the system's 24-hour monitoring of areas that human eyes cannot cover helps reduce oversight costs and improve management standards. For workers, the system quickly issues alarms and stops equipment when danger approaches, allowing them to focus on their tasks with peace of mind.

To maximize these benefits, it is essential first to identify the potential workplace accident risks and associated damages at your site. Then, consider setting up hazardous areas and linking control devices to implement comprehensive hazard prediction systems like InstaGuard, significantly increasing the chances of preventing accidents. Why not take this opportunity to review your workplace safety?

Speak with the Experts

For more details on InstaGuard and how to implement it, reach out to Daifuku Korea. We'll help you with everything from analyzing your site to building the best interface and setting up the system. Our team has the expertise to support your safety management every step of the way. (Please note, as of April 2025, this service is only available within South Korea.)

References:

Choi Jong-seo

Technical Development Manager, Production Division, Daifuku Korea

With over 20 years of experience in designing and controlling automation systems in the automotive and intralogistics sectors, Choi Jong-seo has been dedicated to advancing automation technology. He believes that safety is the foundation of successful automation. This belief has guided his work, especially in addressing the challenge of creating sensors that can accurately detect human presence. Motivated by this need, Choi came up with the InstaGuard System—a groundbreaking solution aimed at significantly reducing workplace safety incidents in industrial settings. Through this project, he hopes to make industrial environments not only more automated but also much safer for everyone.