Health & Safety – One Cornerstone of a Successful Business

Attitudes to workplace heath and safety have evolved greatly over time, and thankfully, both are now well cemented as one cornerstone of a successful business in the modern world. Approaches to health and safety can vary from company to company and country to country. However, simply saying "safety" alone doesn't mean much unless backed up by meaningful action.

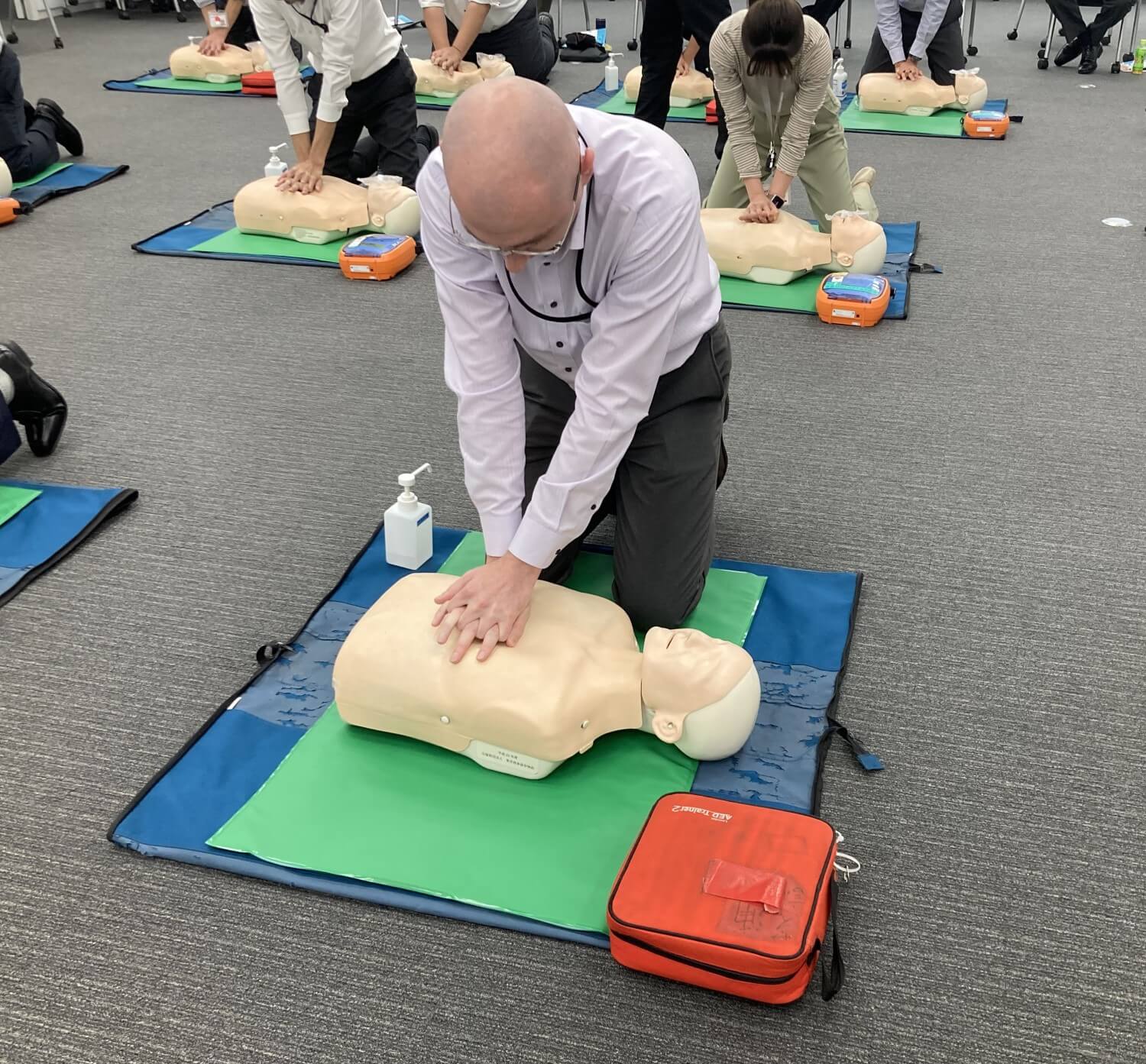

On October 12th, personnel in Daifuku's Tokyo Head Office took part in a training session on emergency first aid. With the topic of heath and safety fresh in everyone's mind, we took the opportunity to talk with the leader of that initiative, Madoka Shoubu, to find out more about safety at Daifuku, related initiatives, and the direction of safety at the Company moving forward.

Intiatives

Interviewer: This emergency first aid course we took part in today is a great initiative. How often do we hold it?

Shoubu: Here at the Tokyo Head Office, we hold this emergency first aid course every year. Under the guidance of the local fire department, we place particular focus on CPR (cardiopulmonary resuscitation) and how to use an AED (automated external defibrillator). Employees looking for a first aid refresh are always welcome, but we're also really encouraging people who haven't taken part yet to join - the goal is to increase the number of people who can help those at the scene of an emergency wherever they may be.

Interviewer: It was a very informative and practical session. I left knowing how to do CPR and use an AED, something I had little knowledge of before. From a health and safety point, what other initiatives are we engaged in as a company?

Shoubu: We have a variety of other efforts and initiatives. For example, we hold periodic disaster drills under the premise of an earthquake directly hitting the Tokyo metropolitan area and also fire evacuation drills.

In addition, the Safety Promotion Department holds heat stroke seminars across our sites here in Japan in collaboration with beverage manufacturers. We also provide thorough traffic safety education, particularly through e-learning, for drivers of company-owned vehicles and commuters who drive their own cars. We're working toward the goal of zero traffic accidents.

Across each of our sites here in Japan we conduct health and safety patrols to facilitate intercommunication on good safety practices that are improving the workplace. One of our most recent examples of this was when there was an accident that took place here at the Tokyo Head Office. It was determined that clear signage would help prevent further accidents of the same kind, and it appears to be working. That same signage was eventually deployed across other sites.

Approach to safety

Interviewer: Have you noticed any changes in Daifuku's approach to health and safety over the years?

Shoubu: While we already had the PDCA cycle of planning, implementing, checking, and improving health and safety, the publishing of ISO 45001 (International Standard for Occupational Health and Safety Management Systems) in 2018 brought a shift in how we look at and assess safety.

The purpose of ISO 45001 is to prevent work-related injuries and illnesses and provide a safe and healthy work environment for all workers involved in an organization's business activities, and it defines the steps that can help a company keep on top of it.

Interviewer: With ISO often recognized as promoting the best practices within many industries, it's importance can't be overstated. What changes did ISO bring specifically within Daifuku Japan from a safety point?

Shoubu: Well, we used to focus on "employee safety," but after the introduction of ISO 45001, that focus widened beyond our direct employees. This saw the focus expand to basically include anyone that has some connection to our business. That includes employees from our partner companies, customers visiting our offices, and even couriers delivering things to our various sites.

Also, the ISO brought some clearer distinctions on how to define hazards. In Japan, until fairly recently the approach to risk assessments focused on the "hazardous situations" and "hazardous events," rather than the "hazard" (source). But even then, both points were lumped together rather than considered distinct elements.

- Hazards (source or situation with a potential to cause injury and ill health)

- Hazardous situations (those where people are present around the hazard)

- Hazardous events (incidents)

Global implementation

Interviewer: It's clear that there are many efforts going on from a health and safety point here in Japan, but can you shed any light on initiatives or systems we have at Group companies outside Japan? At the same time, do we have any initiatives that we run globally?

Shoubu: First, we're actively working on getting all our sites around the world ISO 45001 certified - and many of them now are. In terms of initiatives, some are locally led and targeting local focus areas, and some are linked directly with what we're doing here in Japan.

In terms of locally driven initiatives, one we're seeing now is across our Group companies in North America, where there's focus on ergonomics training with effort toward preventing musculoskeletal disorders.

In terms of global efforts, VR-based risk simulation training that we use at our Anzen Taikan Dojo, which is Daifuku Japan's safety training center, is also being developed and deployed at Group companies in China, Korea, and in the US.

VR based safety training

Safety session with Daifuku Indonesia members

In addition, recently we implemented significant changes to how we do workplace accident reports globally. Before, when looking at accident reports, we found that it was difficult to understand how an accident actually occurred. So, now, we have extra report columns that allow illustrations and pictures, and we also incorporated a why-why analysis to help us identify the root cause of the accident and take measures to address it.

Furthermore, we established our own global safety newsletter as another avenue to share information on the safety activities around the Group and highlight the importance of safety.

Success

Interviewer: Of all the initiatives that we're engaged in, is there any success that stands out in particular?

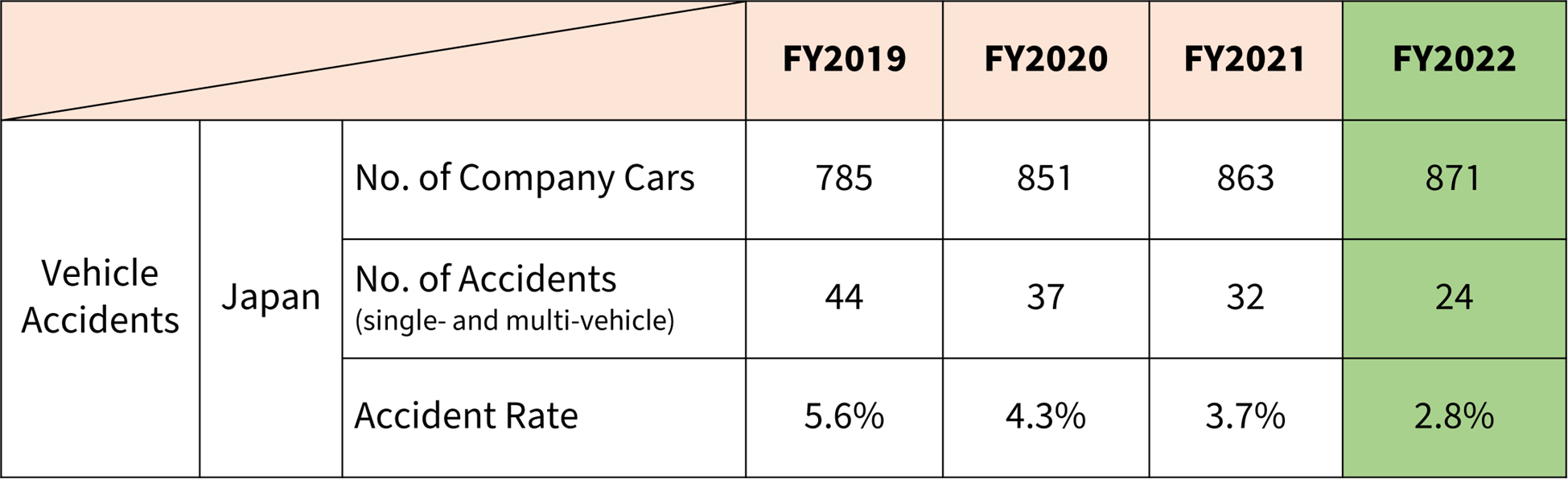

Shoubu: One of the notable successes we have seen is on the driving front. The rate of traffic accidents involving company-owned vehicles has been decreasing as a result of several years of efforts in both hardware and in-house traffic safety education.

Please enlarge the screen to view

Looking to the future

Interviewer: What kind of health and safety efforts or changes are we looking at moving forward?

Shoubu: Given that the number of occupational and traffic accidents is higher among newer employees, we need to take steps to further enhance safety education for them and devise training programs to increase their sensitivity to danger.

Parallel with that, Japan is a "super-aged" society with more than 21% of the population aged 65 or older, and this trend will continue. It'll be essential for the company to implement measures that better support older employees. Currently, our Safety Management Dept. is considering the introduction of fall injury prevention training.

More generally, we have started using an e-learning tool that allows us to conduct short educational programs and tests online to improve occupational health and safety knowledge amongst employees. However, as we're still in the early stages with this, it's something that we want to expand on more.

As many of our employees at the Osaka HQ and Tokyo Head Office are involved in a lot of desk-based computer work, while we already hold some we already conduct workplace exercise sessions, it's something we need to look to expand.

Health and safety is always paramount

Interviewer: Lastly, in your opinion, why is health and safety important to keep in mind?

Shoubu: Good health and safety benefits everyone, not just the company - it's the right thing to do. Through its actions and words, I think that as a company, Daifuku understands this.

Daifuku's safety slogan is "Safety is at the foundation of corporate sustainability and supersedes everything." Our materiality also includes "protect employee safety and health" and "create a workplace environment that motivates employees." A safe workplace delivers peace of mind to personnel. That thinking is in line with the Sustainable Development Goals (SDGs), which call for "health and welfare for all people" and "decent work and economic growth."

Let's continue in our efforts to eradicate occupational accidents and create safe, secure, and comfortable workplaces!

Learn more - health and safety at Daifuku

Learn more about Daifuku's health and safety through the Occupational Health and Safety page on the sustainability section of the Daifuku website.

Madoka Shoubu

Safety Promotion Department, Daifuku Co., Ltd.

Joining Daifuku in 1989, Shoubu worked for Daifuku's bowling business (the Group

moved away from its bowling business in 2017), where she was in charge of website management and the

production of bowling safety booklets. In 2017, Shoubu transferred to Daifuku Co., Ltd.'s Safety and Health

Management Division, where she is engaged in ISO 45001 and safety and health activities at the Tokyo Head

Office and Fujisawa Office.