Leveraging the Power of Warehouse Management Systems (WMS): A Game-Changer for Modern Businesses

If you've ever met me, you will know that one of the first things I encourage all businesses to do is implement a robust Warehouse Management System (WMS).

Why? In today's fast-paced logistics landscape, optimising warehouse operations has become crucial for enhancing overall efficiency, managing inventory and, importantly, increasing revenue and competitive edge.

Having emerged as indispensable tools, WMS has revolutionised how businesses handle inventory, streamline processes, and maximise productivity. These intelligent systems should be the starting point for any warehouse operation – especially when considering automation.

Below I'll outline why implementing a WMS is essential for operational success and the benefits of automation alignment.

1. Enhanced Inventory Visibility and Accuracy

One of the primary advantages of a WMS is the ability to receive real-time visibility into inventory levels and location.

- Provide real-time data and insights into warehouse operations by monitoring inventory levels, order statuses, and overall performance, allowing your business to make informed decisions and respond quickly to changing demands.

- Accurately track stock levels and improve visibility to identify slow-moving items and optimise reorder schedules.

- Automated solutions work seamlessly with a WMS providing real-time inventory levels when items are received, picked, or shipped.

- Businesses can access critical metrics like inventory turnover, order cycle times and order accuracy. Armed with this information, businesses can identify areas for improvement, make informed choices and implement data-backed strategies for future growth.

2. Improved Order Fulfilment Efficiency

Efficient order fulfilment and the ability to track and trace products are essential for customer satisfaction and loyalty. The implementation of a WMS will:

- Streamline order processing, picking, and packing to ensure the right items are shipped to the correct destinations, minimising mistakes and improving fulfilment times.

- A WMS uses advanced algorithms to create optimised pick paths leading to faster, more accurate order processing.

3. Maximise Operational Times

Automated warehouses equipped with WMS can process orders at a faster pace compared to manual systems.

- A WMS streamlines order processing, picking, and packing, leveraging the full capabilities of automation equipment.

- Automated warehouses supported by a WMS can increase operational timeframes with the ability to run a 24/7 schedule.

4. Labour Optimisation

Automation integrated with WMS can reduce the reliance on manual labour for repetitive and physically demanding tasks.

- Automation is proven to reduce human error in tasks such as order picking and inventory management.

- Decreases safety risks through automation.

- Enables businesses to retrain and reskill key staff, focussing on value-added tasks such as quality control, process improvement and exception handling.

- Increases staff productivity with the ability to allocate teams based on demand.

5. Space Utilisation

Integrating a WMS optimises the placement of products within the warehouse, with the ability to organise products based on their characteristics and demand, ensuring efficient use of available space.

- Correct utilisation of warehouse space is essential for minimising operational costs.

- The combination of a WMS and an automated storage solution reduces the need for excess space, leveraging the existing warehouse footprint, and delaying the need for facility expansion.

6. Flexibility

- As business requirements change and grow, an automated warehouse with a robust WMS can quickly adapt to handle increased order volumes and diverse product ranges without significant operational disruptions.

- Data to manage operations and inventory is essential. Having real-time and historical data allows your business to plan for the future accurately.

- A WMS generates a wealth of data on warehouse performance and operations. By analysing this data, businesses can identify bottlenecks, inefficiencies, and opportunities for improvement, leading to continuous optimisation of your warehouse operations.

7. Seamless Integration

WMS solutions are designed to integrate seamlessly with other enterprise systems, such as Enterprise Resource Planning (ERP) and Transportation Management Systems (TMS).

- Eliminate data silos across your business.

- Enhance communication across departments through a unified platform.

- Accurately manage various aspects across your supply chain.

Conclusion

Warehouse Management Systems are no longer a luxury but a necessity for businesses aiming to thrive in today's ever-changing market. By embracing the power of a WMS, you can enhance inventory visibility, streamline operations, and optimise resource allocation to improve overall profitability and sustainable competitive advantage.

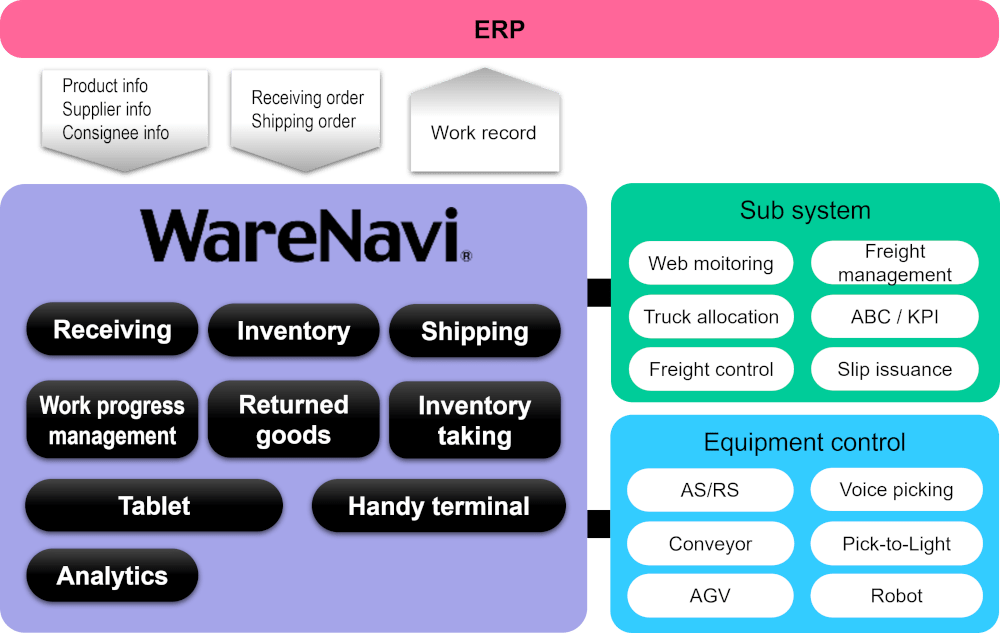

WareNavi

-

Learn about Daifuku's WMS system, WareNavi, or check out our range of automated Intralogistics solutions that the software can accompany.

WareNavi supports material handling system management, task support, progress management, inventory management, and performance aggregation and analysis, and delivers increased efficiency, and controls and supports all distribution center operations, including receiving, storage, replenishment, picking, sorting, and shipping. -

Michael Jee

Executive General Manager, Sales and Marketing – Daifuku Oceania

Michael is a natural born leader in every sense. His approachable nature is matched by his unrivalled enthusiasm, cultivating a world-class culture and results. His inherent ability to recognise, develop and enhance the skills and capabilities of those around him is commonly attributed as the key to his continued success. Having solidified some of the most enviable projects within Intralogistics, Michael's most recent success saw him deliver the largest material handling solution in the Southern Hemisphere, with Amazon's 200,000 sqm AR facility. Michael has been in the industry for 25 years, joining Daifuku Oceania in 2022, having previously worked for Daifuku Europe for six years from 1999.