Is There a Right Time to Retrofit?

Most warehouse managers would agree that upgrading ageing automation systems delivers major improvements in process efficiency, performance and reliability. However, the success of any retrofit upgrade project depends on the timing and scope of the investment. Last minute interventions are often costly and ineffective. To address this, Daifuku has developed a structured approach that employs concepts developed jointly with the customer to fully realize the full potential of automation upgrades. This approach also ensures the plant or distribution centre manager remains firmly in control and experiences minimal impact to existing operations.

Timing is Everything

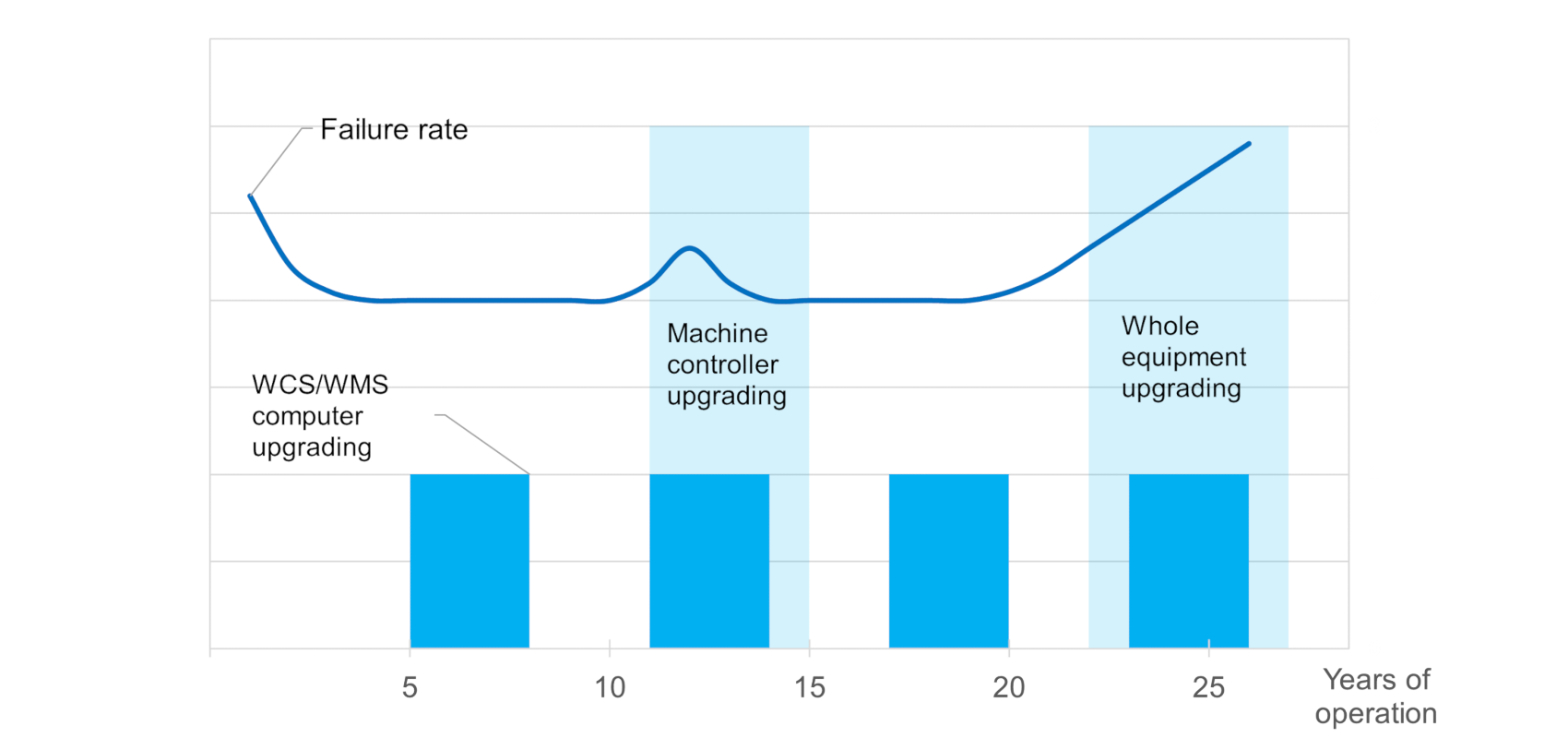

It is never too early to think about the long-term health and maintenance of an automation system. While we all know that the overall performance of a new warehouse system will improve once the technology has truly bedded down (something known as the 'bathtub curve phenomenon'), even the most modern system will inevitably experience entropy – an inevitable erosion of performance delivery and reliability.

New technologies, electronics, monitoring systems and plug-ins are being developed every week. Therefore, it is important to continually monitor technological progress and the commercial demands of the business from the outset, in order to adapt the performance of components and controls. The optimization potential of existing automation systems is enormous, especially with the challenges of sourcing discontinued components, rising energy costs, or difficult spare parts supply. Therefore, a precise analysis of actual needs should be undertaken from the outset to develop a tailored "modernization roadmap."

In practice, the industrial computer hardware used for WCS/WMS systems is normally renewed first, around seven years after initial system integration. After ten to fifteen years, when we can no longer supply spare electronic components for replacement, it is the time for renewal. In this process, key electrical systems and their peripheral components are replaced with the latest models.

Please enlarge the screen to view

Generally, we categorize this part of system maintenance into two distinct phases; 1. Ongoing maintenance & parts exchange and 2. Retrofit of the controller unit.

A sound, long-term upgrade programme takes these different cycles into account. Careful planning is therefore an essential criterion for modernization to minimize disruption to ongoing operations.

Retrofitting is usually done in a step-by-step process. Customers cannot usually stop their entire warehousing or distribution centre operation while upgrades are carried out, so we plan meticulously around the facility, scheduling specific upgrades to minimise disruption. This approach works well for customers, as they can plan budgets to accommodate any scheduled maintenance or upgrade work.

Joined-Up Upgrades

Upgrading any automation system is never done in isolation as changing one element can affect the entire logistics function. Rising energy prices and outdated components drive up warehouse costs, so modernization is understandably attractive to many logistics managers. Modern components and drives offer greater efficiency. For example, Daifuku's latest intelligent controller optimizes the movement of stacker cranes to achieve smooth and minimum movement, resulting in longer machine life.

The Bigger Picture – Process Optimization

We understand that in order to fully exploit the potential of any legacy automation system, the technology, processes and workflows must be critically examined as part of a complete picture. The best approaches to optimization arise from close cooperation with the customer in developing an individual maintenance and modernization programme. This partnership can often result in further tasks that go beyond purely technical issues – sometimes transforming the performance of a warehouse or factory from 'average' to 'world-class'.

Visit Daifuku's Retrofitting page to learn more about our approach to system modernization, related advice, and offerings.

Rainer Joost

Business Development Manager of Intralogistics, Daifuku Europe

Rainer Joost joined Daifuku in 2015 and is a business development manager for its Intralogistics business covering the European market. Rainer graduated with a degree in Business Administration and Engineering and has been in the material handling industry since 1996.

About Daifuku Europe

Established in 1986, Daifuku Europe provides sales, engineering, installation and after-sales services for material handling systems used in manufacturing and distribution in Europe. The company has offices located in the Germany, U.K., Denmark, and Sweden.