How Daifuku’s STV is Solving High-Throughput Pallet Handling Challenges

The focus of the Indian government on local manufacturing has fuelled a remarkable rise in demand for warehousing and logistics solutions. According to a recent Savills India report (1*), an impressive 13.5 million square feet of space was leased in Q4 FY24 to meet logistics demands. Tier I cities saw a 25% increase and tier II and III saw a 20% increase in industrial and warehouse spaces.

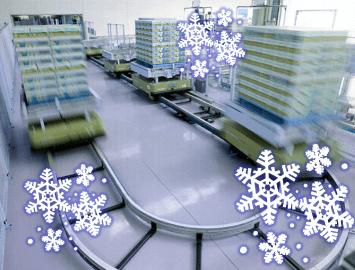

Daifuku Intralogistics India is working to develop and implement advanced warehouse automation solutions capable of meeting the unique demands of various industries. Among such innovations is Daifuku’s Sorting Transfer Vehicle (STV). With features that cater to speed and flexibility, scalability, space efficiency, and operator ergonomics, Daifuku’s STV stands out as a cutting-edge rail-guided vehicle, ideal for high-demand logistics operations.

Understanding the Role of High-Throughput Pallet Transport and Sorting in Modern Warehousing

The primary function of conveying and sorting systems in warehousing and logistics operations is to move and sort materials swiftly and efficiently onsite. In high-throughput environments, conveying and sorting functions are tightly connected, especially when handling pallets across different zones and processes. Efficiency in both movement and sorting is critical to mainlining operational flow.

Industries such as manufacturing, food and beverage, and pharmaceuticals operate under tight timelines, with short inventory turnaround and high demand for rapid order fulfilment. In such high-pressure environments, delays in movement and sorting can cause bottlenecks, negatively impacting productivity, customer satisfaction, and ultimately the bottom line.

When it comes to dealing with high volumes and high throughput in warehouses and distribution centers, rail-guided transport systems like the STV are a natural choice. Many intralogistics companies in India strive to meet the growing demand for speed, reliability, and flexibility, and Daifuku’s Sorting Transfer Vehicle is a tried and tested solution that addresses these needs head-on. Our STVs can reach a maximum travel speed of 200 m/min and are capable of transferring loads at 30 m/min.

How Daifuku’s STV Solves High-Throughput Challenges

In high-throughput environments, challenges such as bottlenecks and limited flexibility can stymie productivity. The STV addresses these common issues in multiple ways:

- 1. Speed and Flexibility for Reduced Bottlenecks

- The high-speed operation of Daifuku’s STV allows materials and goods to be transferred quickly, reducing delays and minimizing bottlenecks. Not only that, but the system’s controller optimizes vehicle allocation to reduce redundant movements, which improves overall efficiency, maintaining the flow of goods and preventing operational slowdowns.

- 2. Increasing Order Accuracy and Reducing Errors

- High throughput environments demand high levels of accuracy. Mistakes in sorting, transferring, or storage can lead to costly delays and inventory discrepancies. Daifuku’s STV, with its precise control and routing capabilities, ensures that goods are transported accurately, reducing human error and enhancing inventory reliability.

- 3. High Redundancy that Keeps Your Operations Running

- When using conveyors to transport and sort pallets between areas, a single point of failure—like a broke motor or conveyor section—can bring your entire operation to a halt. In contrast, the STV has redundancy built into its design. When two or more STVs are in operation, even if one requires maintenance or repair, the remaining STVs will keep running smoothly, ensuring minimal downtime and maximum reliability.

- 4. Scalability for Growing Warehousing Needs

- As businesses expand, their warehousing and logistics needs grow in complexity. The STV offers a level of flexibility that enables facilities to adapt to new demands by increasing the number of STVs or reconfiguring rail routes to handle higher volumes. For many companies, this aspect is a game-changer in addressing the needs of industries experiencing rapid growth.

Daifuku’s Competitive Edge in the Indian Market

Daifuku has distinguished itself with its advanced technology, reliability, and track record of delivering customized solutions for diverse industry needs. Within the Indian market, we have delivered over 450 STVs to customers across industries. As warehouses and distribution centres across India continue to expand and evolve, Daifuku’s STV is emerging as a preferred choice due to its versatility, cost-effectiveness, and ease of integration.

- Supplying raw materials from the warehouse to the production line

- Transferring finished goods to an automated storage and retrieval system (AS/RS)

- Sorting products for shipping

- Supporting case picking operations for order fulfilment

Further, Daifuku offers a cold resistant STV model capable of operating in environments as cold as -30°C, making them ideal for cold-warehouses handling food, pharmaceuticals and other temperature sensitive goods.

-

Supplying raw materials and packaging materials from the warehouse to the production line

-

Sorting for shipping

-

Handling pallet sorting operations in a cold warehouse down to -30 degrees

Summing It Up

As the demand for high throughput pallet conveying and sorting continues to rise, Daifuku’s Sorting Transfer Vehicle stands out as a high-performance solution that addresses the unique challenges of India’s growing warehousing and logistics landscape. Its combination of speed, flexibility, and efficiency makes it ideal for businesses seeking to optimize their operations, improve accuracy, and scale their logistics capabilities effectively.

Material Handling Made Simple

See the STV in operation at some of India's most iconic brands through our YouTube channel, including Everest Spices and Birla Opus. Curious how the STV could revolutionize your operations in India? Connect with our Daifuku Intralogistics India team and take the first step toward smarter, more efficent operations. For other countries, visit our Contact Us page.

Urvashi Giradkar

Senior Marketing Executive, Daifuku Intralogistics India

Urvashi Giradkar joined Daifuku in 2023 and is a Senior Marketing Executive at Daifuku Intralogistics India. An Electronics and Telecommunication Engineer, Urvashi is an integral part of the Daifuku family, contributing to its growth and success.