Apakah Masih Ada Tempat untuk Konveyor Sederhana di Gudang Modern?

Industri penanganan material sedang mengalami masuknya teknologi baru dan menarik yang sering kali menjanjikan untuk merevolusi gudang modern. Sebagai profesional pergudangan, terserah pada kita untuk menentukan teknologi mana yang dapat memenuhi tujuan bisnis kita.

Industri ini telah mengalami berbagai perkembangan teknologi selama beberapa dekade, ada yang menjadi populer dan ada pula yang memudar. Dalam beberapa tahun terakhir, Autonomous Mobile Robots (AMR’s) dan AGV’s telah memasuki pasar. Teknologi ini dapat memperluas penerapan sistem otomatis dan mungkin tumpang tindih dengan penerapan teknologi tradisional. Tumpang tindih ini mungkin membuat kita bertanya, bagaimana teknologi konvensional seperti konveyor masih memberikan nilai dalam gudang modern.

Artikel ini akan mengeksplorasi bagaimana AMR dibandingkan dengan konveyor, otomatisasi gudang yang lebih tradisional.

Menilai kelayakan konveyor dalam otomatisasi gudang: apakah ini masih merupakan solusi yang layak?

Sepanjang sejarah, manusia secara konsisten menemukan cara-cara inovatif untuk mengangkut barang dari satu lokasi ke lokasi lain. Konveyor telah digunakan dalam beberapa bentuk selama lebih dari 230 tahun.

Segalanya mulai meningkat selama revolusi industri ketika Henry Ford terkenal menggunakan konveyor untuk meningkatkan produktivitas di jalur perakitannya. Saat ini konveyor modern telah berkembang menjadi tulang punggung rantai pasokan intralogistik modern. Evolusi sistem konveyor menjadi bukti kecerdikan dan keinginan serta kebutuhan kita untuk memindahkan barang dalam jumlah besar ke seluruh masyarakat. Konveyor modern dapat memindahkan material sekecil sebutir beras ke tanah dan batu dalam jumlah besar di industri pertambangan.

Keuntungan

Dalam intralogistik, konveyor dapat menangani berbagai jenis paket termasuk polibag, karton, tas jinjing, sampah, dll. Konveyor telah berevolusi dari sekadar mengangkut material menjadi menyediakan penyortiran untuk mendukung proses bisnis. Salah satu keuntungan utama konveyor adalah beragamnya modul yang telah dikembangkan, dan banyaknya penelitian dan pengembangan yang telah dilakukan selama 100 tahun terakhir. Bahkan saat ini, konveyor masih dapat diandalkan, cepat, dan mapan dalam industri penanganan material.

Oleh karena itu, kemampuan sistem konveyor untuk menghubungkan berbagai bagian dan area gudang modern secara andal tidak ada bandingannya. Sistem ini dapat menyediakan lebih banyak throughput dan paket perutean yang lebih andal untuk lebih banyak operasi dibandingkan teknologi lainnya.

Kekurangan

Meskipun konveyor bukannya tanpa batasan, beberapa kelemahan terbesar dari solusi berbasis konveyor adalah ruang dan fleksibilitas. Konveyor dan semua struktur pendukung yang diperlukan untuk menjaganya tetap di tempatnya dapat menghabiskan ruang dengan cepat. Terlebih lagi dengan memakan ruang, konveyor dibaut pada tempatnya dan tata letaknya menjadi tetap. Aliran atau proses baru mungkin memerlukan upaya yang signifikan, yang dapat menjadi tantangan dalam lingkungan penanganan material yang dinamis.

Mari kita melihat lebih dekat AMR untuk melihat bagaimana mereka memberikan perspektif baru terhadap industri ini.

Memperluas jangkauan transportasi dan penyortiran otomatis dengan robot bergerak otonom (AMR)

Robot bergerak otonom, umumnya dikenal sebagai AMR, adalah robot canggih yang dapat menavigasi lingkungannya dan menangani tugas tanpa memerlukan campur tangan manusia.

Keuntungan

Berbeda dengan Automated Guided Vehicle (AGV) tradisional, AMR tidak memerlukan jalur yang telah ditentukan sebelumnya. Sebaliknya, mereka menggunakan kombinasi sensor real-time, teknologi pemetaan seperti Simultaneous Localization and Mapping (SLAM), dan Artificial Intelligence (AI) untuk bergerak di sekitar fasilitas dengan cara yang lebih dinamis dan fleksibel. Dengan menggunakan teknologi canggih ini, AMR memperluas kemungkinan penerapan otomatisasi dan membawa manfaat signifikan bagi berbagai industri.

Salah satu keuntungan terbesar sistem AMR dibandingkan solusi konveyor tradisional adalah fleksibilitas. AMR tidak memerlukan trek atau peralatan tetap dalam jumlah besar. AMR dapat bergerak bebas melalui ruang terbuka yang luas, memungkinkan pelanggan memindahkan produk ke seluruh gedung dengan lebih sedikit batasan ruang. AMR juga dapat berinteraksi di luar angkasa dengan manusia. Tidak perlu pagar pengaman atau jalur perjalanan tetap.

Manfaat utama lainnya dari sistem AMR adalah skalabilitas. Dengan sistem AMR Anda dapat memulai dengan satu robot dan menambahkan robot tambahan untuk meningkatkan produktivitas. Hal ini memungkinkan pelanggan untuk masuk ke sistem dengan biaya masuk yang lebih rendah, menjadikannya pilihan ideal bagi usaha kecil dan menengah yang ingin mengotomatisasi operasi mereka tanpa mengeluarkan banyak uang.

Kekurangan

Seperti halnya teknologi apa pun, ada keterbatasan pada AMR dan cara penerapannya. Salah satu kelemahannya adalah kecepatan instan. Meskipun Anda dapat menskalakan sistem dengan beberapa robot, ada batasan berapa banyak volume yang dapat diambil atau dikirim ke titik tertentu. Kekhawatiran lainnya adalah betapa barunya beberapa fitur di beberapa sistem ini. Meskipun AMR telah menunjukkan dalam beberapa tahun terakhir bahwa mereka adalah solusi yang terbukti dan dapat diandalkan, dalam banyak kasus kita tidak selalu memiliki contoh studi kasus spesifik untuk solusi tertentu. Seringkali pelanggan merasa bahwa mereka benar-benar memasuki perkembangan teknologi mutakhir dengan pengalaman pengujian berulang.

AMR memang memiliki biaya berkelanjutan di luar harga pembelian awal. Lucas Systems memperkirakan bahwa biaya tahunan untuk pemeliharaan AMR adalah 20% dari biaya modal. Baterai perlu diganti sekitar lima tahun sekali, dan ini merupakan biaya yang signifikan tergantung pada ukuran armada. Ada biaya lain yang perlu dipertimbangkan seperti pembaruan perangkat lunak, konfigurasi ulang sistem, dan pelatihan.

Menemukan keseimbangan yang tepat: teknologi tradisional vs. modern di pergudangan

Kesimpulannya, ketika membandingkan sistem konveyor tradisional dengan robot bergerak otonom (AMR), penting untuk mempertimbangkan kebutuhan dan tujuan spesifik operasi gudang Anda. Meskipun konveyor tradisional menawarkan keandalan dan efisiensi untuk aplikasi tertentu, AMR memberikan fleksibilitas dan kemampuan beradaptasi terhadap lingkungan gudang yang dinamis. Pada akhirnya, pendekatan hybrid yang menggabungkan kekuatan kedua teknologi dapat menawarkan solusi paling komprehensif untuk mengoptimalkan produktivitas dan efisiensi dalam operasional gudang.

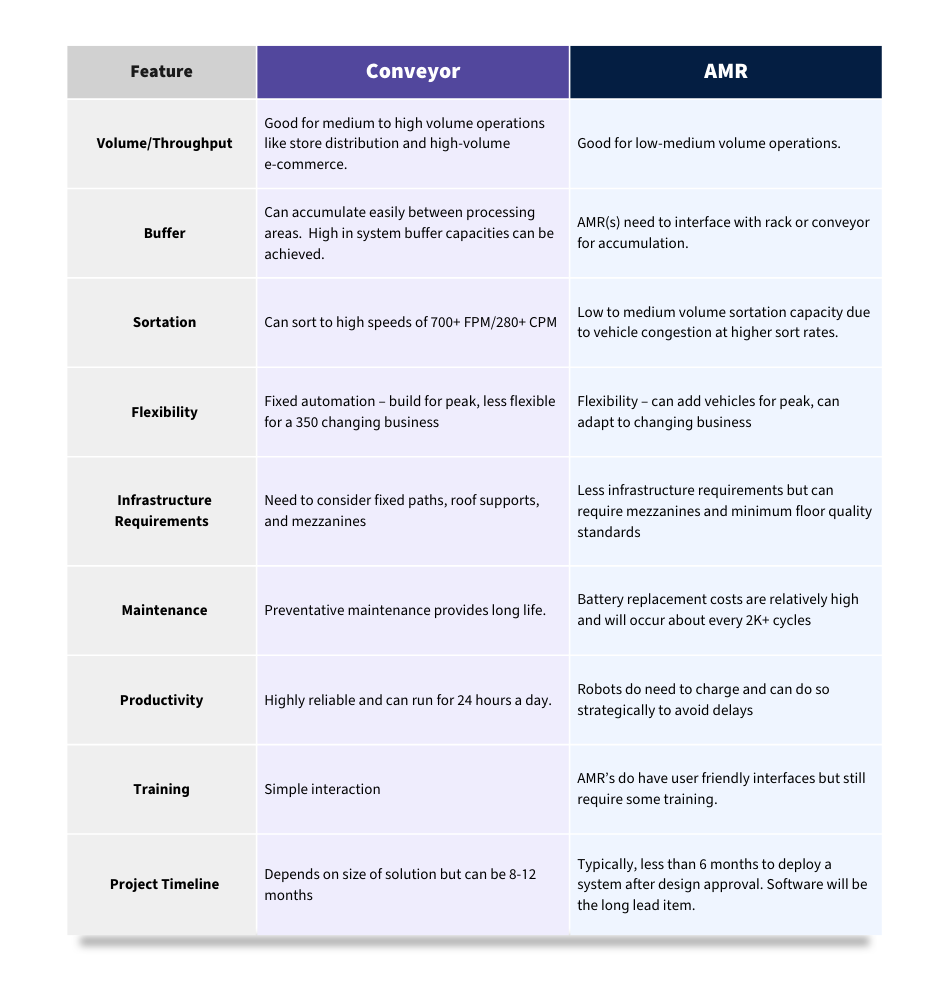

Harap perbesar layar untuk melihat

Dengan mengintegrasikan kemajuan ini, Anda dapat tetap mendapatkan informasi terkini dan meningkatkan operasi gudang Anda sekaligus menjaga bisnis Anda berjalan lancar. Menemukan solusi penanganan material yang tepat dapat meningkatkan efisiensi operasi gudang Anda secara signifikan.

Di Daifuku Intralogistics America, kami menawarkan berbagai macam produk dan teknologi yang dapat dikombinasikan untuk menciptakan sistem canggih yang disesuaikan dengan kebutuhan bisnis Anda. Kami berkomitmen untuk membantu Anda mencapai solusi pergudangan generasi berikutnya yang dapat mendorong pertumbuhan dan keberhasilan bisnis Anda.

Batu Giovanni

Wakil Presiden Senior, Daifuku Intralogistics America

Giovanni Stone telah bekerja di Daifuku Intralogistics America selama lebih dari 15 tahun, dan selama ini, ia telah mendapatkan reputasi sebagai pemecah masalah dan pemimpin yang luar biasa. Ia berkomitmen pada keunggulan dan secara konsisten membantu timnya tampil sebaik mungkin.

Sebagai tokoh kunci dalam perusahaan, Giovanni menyelaraskan strategi penjualan dan produk Daifuku dengan aset intinya: sumber daya manusia, proses, dan teknologi. Dia teliti dalam pendekatannya dan menggunakan wawasannya untuk memastikan bahwa perusahaan tidak hanya memenuhi tetapi juga melampaui targetnya. Dia berfokus pada memaksimalkan nilai pemangku kepentingan dan mendorong pertumbuhan yang menguntungkan.

Sebagai Wakil Presiden Senior, Giovanni terus membangun rekam jejaknya yang mengesankan dalam pelaksanaan otomatisasi tingkat lanjut. Dia memberikan perspektif baru pada posisi penjualan Daifuku, mengidentifikasi peluang pasar, menciptakan nilai bisnis yang nyata, dan mengatur ekspansi yang lancar.

Pandangan visioner Giovanni menguntungkan klien Daifuku secara langsung. Dia serba bisa, berkolaborasi lintas fungsi, dan memiliki jaringan profesional yang luas, yang semuanya meningkatkan pengalaman mereka. Dia adalah katalisator perubahan positif dan fokus pada pengambilan keputusan, keunggulan organisasi, dan menumbuhkan budaya pemenang untuk memastikan bahwa Daifuku tetap menjadi yang terdepan dalam inovasi.