Intralogistics Innovation Center

The Daifuku Intralogistics Innovation Center, based in Chicago, Illinois, features the advanced technology solutions of Daifuku, the world’s leading provider of material handling systems. In addition, the facility is wheelchair accessible, part of our effort towards the realization of a universal design.

| Building area | 5,580 sq. m (60,065 sq. ft) |

|---|---|

| Operation hours | 8:00-17:00 (Reservations required) |

| Closed | Saturdays, Sundays & Holidays |

Facility Outline

Training

Our multimedia training center offers a dedicated classroom setting paired with immediate access to hands-on experience with our advanced material handling technologies. The facility supports a variety of learning programs, including our Advanced Technology Training designed specifically for Integrator Partners, as well as ongoing internal education and professional development courses.

Conference Room

The Board Room is an executive-style meeting space designed to accommodate up to 30 participants. It features a full-service kitchenette and offers a clear view of the cutting-edge material handling technologies showcased within the Daifuku Intralogistics Innovation Center.

Unit-Load AS/RS

Daifuku’s Automated Storage and Retrieval System (ASRS) has been developed to meet the unique challenges and evolving demands of a wide range of industries.

This advanced solution delivers exceptional versatility and efficiency, offering both single and multi deep storage options that can accommodate up to eight products deep, with a maximum system height of 40 meters (approximately 130 feet). Its robust design allows seamless operation in even the harshest environments, including freezer applications down to -30 °C (-22 °F).

The storage and retrieval machines are highly adaptable, supporting a broad range of load types — from pallets and long or irregular objects to rolls, automotive bodies, and more — with load capacities of up to 6,600 pounds. For higher throughput applications, Daifuku can configure the system with enhanced features such as dual cranes in a single aisle, ensuring maximum efficiency and performance.

At Daifuku, every ASRS project is tailored to the specific needs of the client. Our team of experienced engineers takes the time to understand each operation, product mix, and facility layout, ensuring that every system we design delivers the best possible solution for its intended application.

Mini Load AS/RS (Shuttle Rack M)

The Shuttle Rack is an advanced, high performance storage solution designed for maximum efficiency and versatility.

It supports both single and double deep storage configurations and can reach a height of up to 18 meters (59 feet), making it ideal for high bay warehouse environments. Engineered for reliability in a range of temperatures, the Shuttle Rack operates seamlessly in freezer environments as low as -30 °C (-22 °F).

It can handle load units weighing up to 88 pounds and accommodates a variety of load types, including cases, totes, and trays, within the same aisle. To further optimize throughput, the system supports a triple load lifter, allowing multiple units to be handled simultaneously.

Coming soon, the Shuttle Rack MX will introduce an additional dimension of travel, offering even greater storage and retrieval capabilities for the evolving demands of modern intralogistics.

Sliding Shoe Sorter (AS35)

The AS35 is the world’s highest throughput sorter, spanning up to 1,000 feet on a single drive, running at 750 FPM, and handling over 400 cases per minute.

It features a maintenance-friendly, PLC-controlled system with patented, calibration-free technology, sealed-for-life chain, and positive divert confirmation.

Capable of sorting totes, trays, cartons, mailers, and polys with top-tier precision, the AS35 meets the demands of the most complex operations.

Conveyor, Sortation and Structures

The Daifuku Intralogistics Innovation Center features a fully integrated, closed loop conveyor and sortation system, allowing visitors to experience these technologies in action. This advanced setup not only showcases the efficiency and precision of our equipment, but also serves as a test site where we can run proof of concept trials using actual client products, supporting both custom solution design and ongoing internal research and development.

In addition, the Innovation Center highlights a range of custom metal fabrication capabilities, including mezzanines, conveyor support structures, and safety railings. Our expertise also covers the design and manufacture of catwalks, safety ladders, stairways, stair towers, and other custom built structural elements, tailored to meet the unique operational and safety needs of each facility.

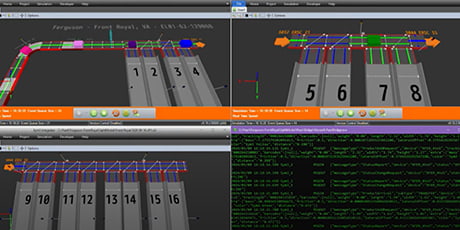

Simulation/Emulation

At Daifuku Intralogistics, we ensure the success of every solution through a multi-stage system validation process—powered by cutting-edge simulations and digital twin emulations.

We begin with discrete event simulations—used during the initial concept phase to validate ideas and explore possibilities. These models replicate high-precision equipment behavior to reveal system dynamics early on.

Next, we leverage digital twin emulations—for both our Warehouse Execution System (WES) software and equipment controls.

These emulations let our engineers test, tune, and commission systems in a virtual environment—mirroring real-world performance under high-volume and scenario-specific conditions.

From macro-level flows to micro-level details, our models enhance system quality and reliability—ensuring every deployment runs smoothly from day one.

Robotics

At Daifuku Intralogistics America, our latest generation of the Robotic Delayering and Singulation System (RDS) delivers a trusted, well-established solution for one of the most labor intensive warehouse tasks: efficiently removing products from pallets and seamlessly conveying them downstream as single, properly oriented cases.

Through advanced automated sensing and sequencing, the RDS processes pallets with varying layer heights and removes slip sheets when present. What sets this newest generation apart is its industry leading compact footprint — a revolutionary enhancement that optimizes space utilization without compromising functionality. The result? Greater layout flexibility and expanded floor space configuration options for your warehouse.

Innovative, efficient, and space conscious, the new RDS redefines automation in material handling.

Narrow Belt Live Roller Accumulation

The Narrow Belt Live Roller (NBLR) conveyor is a comprehensive system that improves your productivity and profitability. It is a product that Daifuku developed to match the market demand.

The system works by creating gaps between items, preventing them from slamming into each other when they stop—an issue that can cause carton rotation, side-by-side alignment, and ultimately, jams. This way, you can transport delicate things safely and efficiently.

The NBLR is a smart conveyor system that makes factories run faster and smoother. It works well with cardboard boxes and totes. The system is smart because it has some clever design features that keep the products in singulated flow to minimize product jams.

Interactive Kiosks

Interactive kiosks enable visitors to explore and learn more about the range of product applications featured in the Daifuku Intralogistics Innovation Center. Through these kiosks, guests can view detailed videos, rendered engineering drawings, and specification sheets for each technology on display, gaining a deeper understanding of their capabilities and benefits.

Directions

Please click here for the map.

Approximately 3 minutes north of the I-55 Weber Road Exit

Daifuku Intralogistics America Corporation

1325 Rodeo Dr, Bolingbrook, IL 60490