Logis-Tech Tokyo 2024: Daifuku’s Latest Technologies and Future Automation Solutions

Logis-Tech Tokyo 2024—one of Asia’s largest logistics and distribution exhibitions—was held at Tokyo Big Sight from September 10 to 13. During the four days of the show, Daifuku exhibited at its booth under the theme “Automation of Tomorrow” using CG imagery powered by the latest 3D technology, as well as displaying actual systems; with a focus on AGVs. In addition to offering a detailed look at the Daifuku booth, this article introduces Daifuku’s latest technologies and upcoming automation solutions for logistics centers, semiconductor fabs, automotive factories, and airports.

Using 3D imagery to propose completely automated logistics centers and flexible AGV-based automotive production lines

At the Daifuku booth, a 10-minute presentation, featuring the combination of a live speaker and a 3D video showcasing Daifuku’s vision for future automation solutions displayed on a 22-meter-wide, 3.6-meter-tall screen equipped with the latest 3D LED system.

This video offered a look at the fully automated solutions Daifuku hopes to put into practice in the manufacturing and distribution field by 2030. From receiving to shipping, the proposed solutions ensure fully automated logistics centers, with product data reliably linked to orders in real-time and transfer robots seamlessly connecting every step. Picking robots and AGVs would also be used to fully automate piece picking.

In the cleanroom field, Daifuku also illustrated the scale of “giga-fabs,” large-scale semiconductor manufacturing plants, as well as transport systems for back-end processes where automation is progressing. Daifuku’s proposed material handling systems use AI to optimize transport vehicle routes, improving the efficiency of semiconductor manufacturing.

Depalletized cases are seamlessly transferred with robots.

Vehicles travel along overhead rails in a massive semiconductor fab.

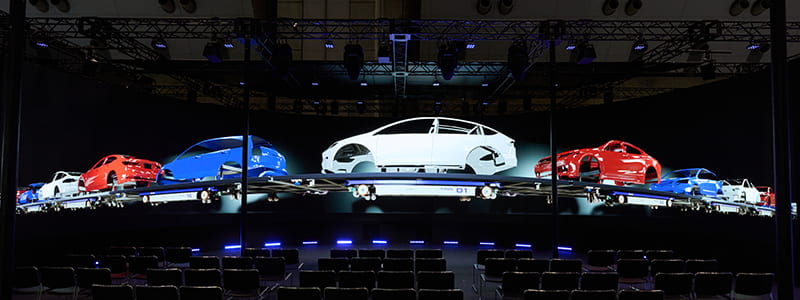

In the automotive manufacturing field, Daifuku’s system would utilize AGVs to accommodate production lines for electric vehicles (EVs) and other novel forms of mobility. The solution could also be easily adapted to handle additional specialized production lines, or the expansion or contraction of production lines due to changes in production volume. Automation could also be extended to parts logistics—from receiving to supplying and returning.

In the airport field, Daifuku also presented how its systems could handle checked baggage using RFID tags linked to flight data, ensuring reliable security and accuracy. Storing baggage temporarily in shuttle-based automatic storage and retrieval systems (AS/RSs) could also optimize the timing of when bags are loaded onto flights before departure. In addition to loading baggage onto flight containers, this automation solution could also be used for providing passengers with services such as real-time flight and baggage location information, creating a truly smart airport.

An AGV tows carts loaded with vehicle bodies.

Facial recognition allows for automated check-in at baggage check kiosks.

The exhibition area of the booth focused on AGVs and featured newly launched products that attracted significant interest.

SOTR Series Sorting Transfer Robots

One of the featured products was the SOTR-S piece sortation system (pictured). Each robot in this system receives real-time information from controllers and moves at high speeds (180 meters per minute) guided by matrix codes. Trays on the robot tilt on both sides to sort products into different chutes, enabling construction of a compact, highly efficient sorting system. The system also supports two-tier operation with lifters to minimize traffic jams. Other products on display included the SOTR-M for case and container transport, and the SOTR-L for pallet transport and sortation.

Cleanway CLW-08K Semiconductor Back-end Process Transport System

The Cleanway series of systems already has a strong track record in front-end processes of semiconductor manufacturing, and Daifuku is creating new models designed to meet the growing automation needs in back-end processes. In these processes, different materials need to be transported according to each step of production. For this exhibit, as part of the various systems developed to meet the requirements of customers, Daifuku showcased the new CLW-08K model designed for transporting specialized material containers.

TRVS AGV for Automotive Production Lines

Capable of towing a cart with a vehicle body on it, the TRVS AGV can pull loads of up to 6.5 tons, or more than 10 tons when multiple units are connected, helping to meet the more demanding requirements of heavier EVs. The TRVS can also travel in any direction—forward, backward, sideways, diagonally, around corners, and in circles—and is flexible enough to be utilized in production lines for EVs, hybrids, and gasoline-powered vehicles.

MIT AGV-based Baggage Inspection Platform

The MIT automates the transportation of checked baggage to additional inspection points. The introduction of this system eliminates the strenuous manual labor of removing and returning baggage from and to the conveyor. Currently, over 500 MIT systems are in operation across 10 U.S. airports. Daifuku plans to continue to develop automated systems for airports using similar technology.

Toward our vision for 2030

In May 2024, Daifuku announced its long-term vision Driving Innovative Impact 2030. To realize this vision, Daifuku is dedicated to advancing the research and development of next-generation technologies, introducing solutions and products like those shown in its Logis-Tech Tokyo 2024 Automation of Tomorrow presentation, and creating new value for society.