Daifuku Eco-Products

- Daifuku Eco-Products

Certification Program - Manufacturing & Distribution

- Cleanroom

- Automotive

- Car wash machines

and related products - Electronic products

In fiscal 2022, The Daifuku Eco-Products Certification Program was revised. In fiscal 2024, we began sustainability performance assessments in order to make evaluations from a broader perspective, including contributions to customers and society in addition to consideration for the environment.

Contributing to the Environment and Society with Our Products

Daifuku Eco-Products Certification Program

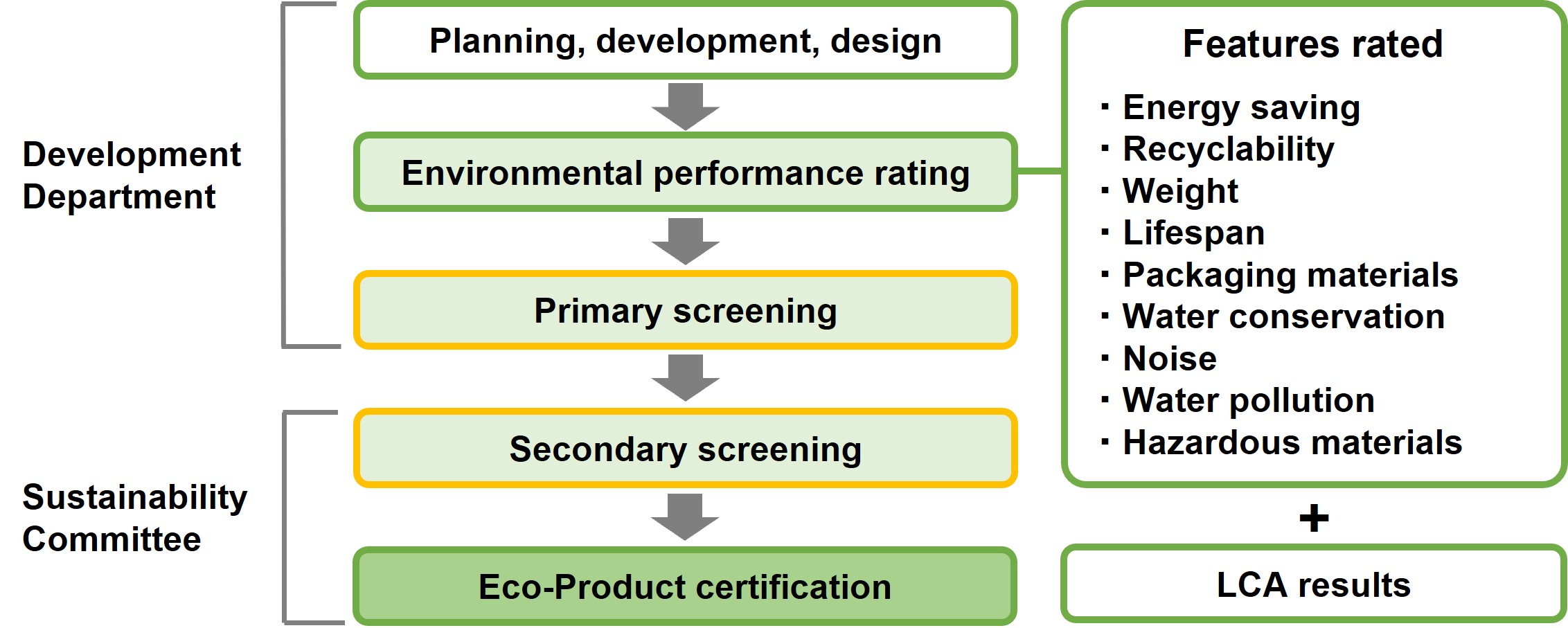

In 2012, Daifuku began its Daifuku Eco-Products Certification Program, which certifies products based on an environmental impact assessment rating and a certification system using the Group's own standards. Under the program, all products across the Group are measured under the same standards, with measurements coming from the results of a Life Cycle Assessment (LCA) and performance assessments on a number of areas, including energy saving, recyclability, weight, lifespan, packaging materials, water conservation, noise, water pollution, and hazardous materials. As of May 2023, 83 products have met the standards and been certified as Daifuku Eco-Products.

Certification process

To obtain a valid and trustworthy rating from multiple perspectives, the screenings are done at a certification meeting organized by officers from different business units.

Certified Daifuku Eco-Products (Year)

Manufacturing & Distribution

- Sorting Transfer Robot-L (2022)

- Case sorting system - Cross-belt Sorter (2020)

- Mini load AS/RS post and beam type wide truss rack (2019)

- Mini load AS/RS - H-P10 (2019)

- Mini load AS/RS - Shuttle Rack (SRS-M Double Deep) (2018)

- High-speed transport vehicle - Sorting Transfer Vehicle (STV-HS100A) (2017)

- High-throughput picking station - Quick Pick Station (2017)

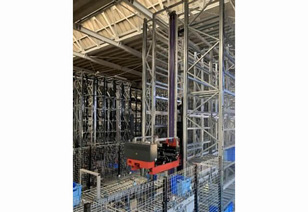

- Stacker crane - R-series S/R machine (2016)

- AS/RS - Seismic damper unit for rack (2016)

- Stacker crane - Rack Master (R-L10) (2015)

- Bolt-up Rack (DC100) (2015)

- Mini load AS/RS - Shuttle Rack (SRS-M) (2013, 2014)

- AS/RS for long objects (2014)

- Transport system - Motor Roller Conveyor (2013)

Cleanroom

- Power supply unit for the wireless power supply system HID “HID4-BA” (2022)

- Cleanroom transport system - Clean Space Carrier (CSC/D8050MⅡ) (2021)

- 10G FPD cassette transporting system (2018)

- Green HID Inductive Wire 500 m (2017)

- Cleanroom equipment - Mechanical Centering System (2016)

- Cleanroom transport system - Clean Space Carrier (CSC/D6000MⅡ) (2015)

- Cleanroom transport system - Cleanway (CLW-08v2) (2014)

- Cleanroom transport/storage system - MMHS (Matrix Material Handling System) (2013)

- Cleanroom transport system - Clean Space Carrier (CSC/D-5500M) (2013)

- Cleanroom storage system - Clean Stocker (CLS/D-6000HS, D-8050, D-8050L) (2012)

Automotive

- Heavy-duty, low-profile Slat Conveyor (2022)

- Distributed HID power supply system - D-HID (2021)

- Drive-through truck station - TRTS (2020)

- Standard controller for the Flexible Drive System - FDC (2019)

- Tablet control panel for automotive production lines (2018)

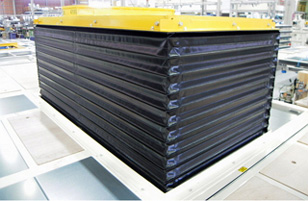

- Skillet conveyor with lifting device - Scissor lift (2017)

- Chainless conveyor system - Flexible Drive System (FDS-FL15) (2016)

- Temporary storage and sortation system - SPDR (2015)

- Pallet-type conveyor system - Flexible Drive System (FDS-FLP, load bar turn) (2014)

- Power assisting system - ECO POWER ASSIST (2013)

- Automobile paint line system - E-DIP (2012)

Car wash machines and related products

- One-way drive-through car wash machine - Treus (TE7000) (2021)

- One-way drive-through car wash machine - Twinfect Riscia (TFR200) (2020)

- Space-saving gate-type car wash machine - Zechs (2018)

- Tunnel-type car wash machine - Magic Thru (MT2260) (2017)

- Large-vehicle car wash machine - Camion Custom (CN8100) (2017)

- Gate-type car wash machine - GSPECT (2012)

Electronic products (Contec Co., Ltd)

- Embedded computer (EPC-C5000) (2022)

- Box computer (BX-M210-J2311) (2022)

- Industrial edge AI computer (DX-U1220-3E0212) (2022)

- Box computer (BX-T3000) (2021)

- Raspberry Pi expansion board (CPI-DIO-0808L) (2021)

- Battery-driven BLE-LTE converter supporting IP67 (CPSB-BTM1-S011) (2021)

- Box computer (BX-U200) (2020)

- Box computer (BX-M1500) (2020)

- Lamination signal measuring unit (CPS-PAV-AE01-JP) (2020)

- Insulated analog input unit (AI-1608VIN-USB) (2019)

- Panel computer (PT-970W10WA) (2019)

- Box computer (BX-T1000) (2018)

- High-speed GPIB communication micro converter (GPIB-FL2-USB) (2018)

- Factory automation computer (VPC-700) (2018)

- M2M Controller CONPROSYS nano (CPSN-MCB271-S1-041) (2017)

- RS-232C communication unit (COM-4CN-USB) (2017)

- Ruggedized switching hub (SH-8008F) (2016)

- Solar power generation data measurement and display device - SolarView Battery (SV-BPX-MC310) (2016)

- Stack-type controller - EtherCAT (CPS-ECS341-1-011) (2016)

- Compact box type computer (BX-320) (2015)

- M2M Controller (CPS-MC341-ADSC1-111) (2015)

- Solar power measurement display system - SolarView Compact (SV-CPT-MC310) (2014)

Manufacturing & Distribution

Sorting Transfer Robot-L

- Energy Saving

- CO2 Reduction

- Lightweight

The Sorting Transfer Robot-L is an automated pallet transport vehicle. Compared to our original Sorting Transfer Vehicles (STV), which are used for cargo handling in automated warehouses, the Sorting Transfer Robot-L eliminates the need for conveyors and rails, enabling a significant simplification of the equipment. As a result, it is 63% lighter, operates efficiently according to the quantity of cargo to be transported and the conditions of the cargo handling equipment, and uses 11% less power.

Case sorting system - Cross-belt Sorter

- Energy Saving

- CO2 Reduction

This cross-belt sorter is a looped high-capacity case-sorting system comprising vehicles equipped with a belt conveyor. The power supply to the belt conveyor uses the rotation of the vehicle ’s wheels, and electrical power is supplied efficiently from an electricity-generating motor. Power consumption is also lower than that of previous models.

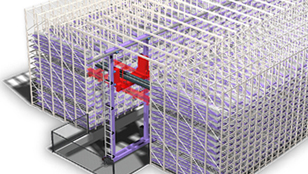

Mini load AS/RS post and beam type wide truss rack

- Lightweight

- CO2 Reduction

The mini load AS/RS post and beam type wide truss rack is suitable for holding containers. Compared to arm-type racks, the number of trusses has been reduced to about one fifth, greatly improving workability. Also, reducing the number of parts by about 70% and making them more lightweight has contributed to a reduction in environmental impact during production.

Mini load AS/RS - H-P10

- Energy Saving

- CO2 Reduction

The H-P10 model is a high-performance mini load AS/RS for multi-tenant storage. Using special transfer devices enables loads to be stored and retrieved simultaneously, thereby decreasing overall transfer time. Further, changing the frame structure from two masts to one has greatly reduced weight. Additionally, power consumption has been reduced by 27% compared to conventional models.

Mini load AS/RS - Shuttle Rack (SRS-M Double Deep)

- Energy Saving

- CO2 Reduction

- Lightweight

Double-deep configurations have been added to this high-throughput AS/RS (certified in fiscal 2014) that has a shuttling vehicle positioned on each rack level. Loads can be stored double deep onto a shelf for improved storage efficiency. Compared to automated storage systems with a double-deep configuration that use stacker cranes, this system can reduce power consumption by approximately 85% per cycle.

High-speed transport vehicle - Sorting Transfer Vehicle (STV-HS100A)

- Energy Saving

- CO2 Reduction

When combined with an automated warehouse system, the Sorting Transfer Vehicle forms an integrated transport system with high capability. A refined frame structure with fewer control boxes results in 9% lower weight, and the use of high-efficiency motors realizes a 10% reduction in electricity consumption and a 10% reduction in CO2 emissions and energy consumption compared to earlier models.

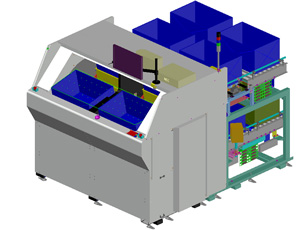

High-throughput picking station - Quick Pick Station

- Energy Saving

- CO2 Reduction

- Lightweight

Designed mainly for continuous operation at delivery centers of the parcel delivery and mail order industry, this goods-to-person picking system ensures high-throughput of high-frequency items. While processing power is about twice as high as earlier models, the number of parts has been reduced by 59% and the weight by 31%. This results in a 9% reduction in electricity consumption, and a 21% reduction in CO2 emissions and energy consumption compared to earlier models.

Stacker crane - R-series S/R machine

- Energy Saving

- CO2 Reduction

The R-series S/R machine is a stacker crane that stores and retrieves pallets into and from racks. The technologies implemented on the R-L10 model S/R machine, which was certified as an eco-product last year, has now been spread to all R-series models. Its refined frame structure and use of premium efficiency motors contribute to a 6% reduction in electricity consumption, and a 5% reduction in CO2 emissions and energy consumption compared to conventional models.

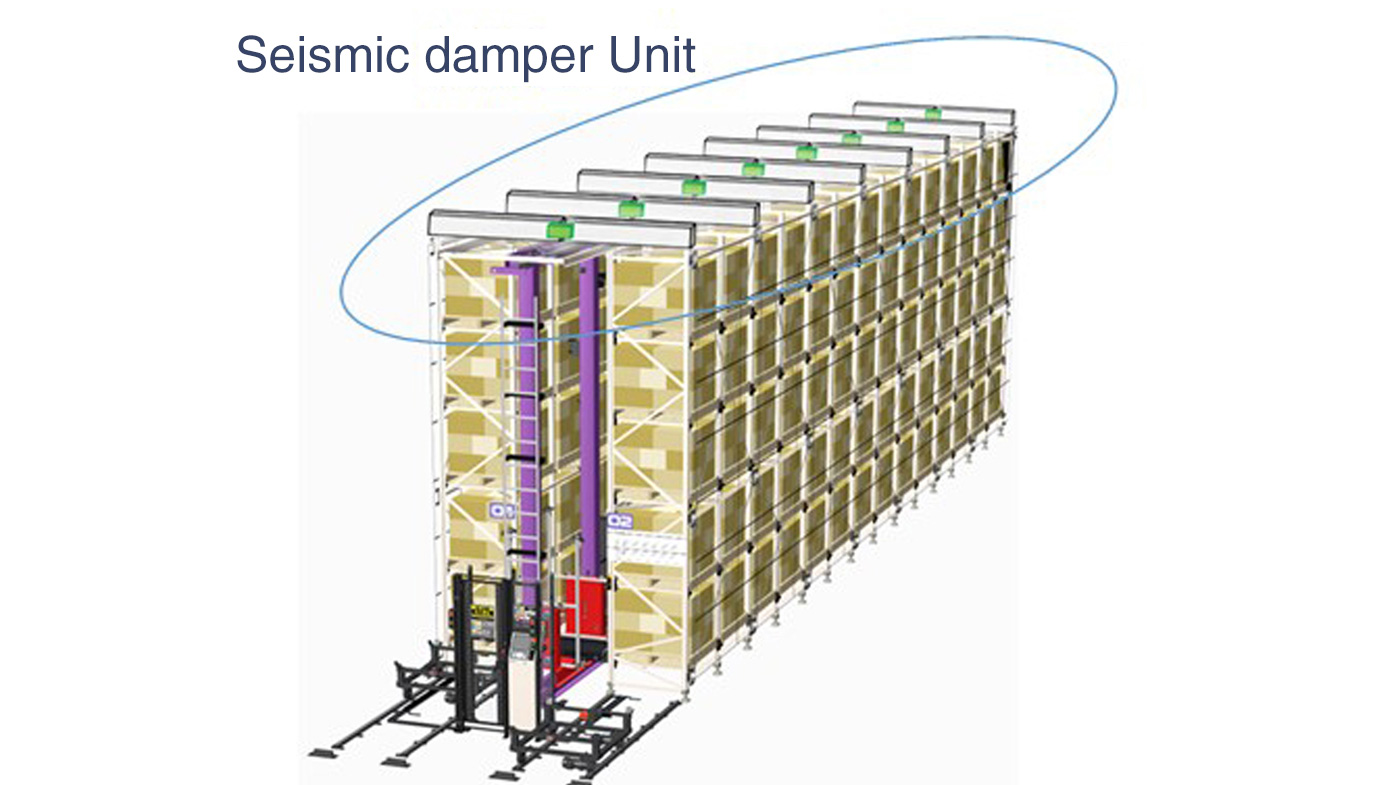

AS/RS - Seismic damper unit for rack

- Lightweight

- CO2 Reduction

The seismic damping rack is one of our anti-seismic products. In the event of an earthquake, the seismic damper units installed at the top of the racking structure absorb the seismic vibrations, which prevents the stored items from falling off the racking. Changed from the conventional arrangement, the dampers are now at the center of the S/R machine aisle. This modification has led to a decrease in the required number of dampers, and an increase in rigidity that has also brought a about decrease in size of the beams of the damper unit. These factors add up to a 20 % decrease in weight, and a 19 % decrease in CO2 emission and energy consumption.

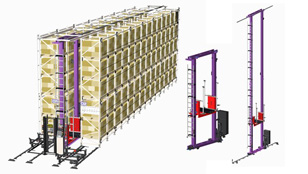

Stacker crane - Rack Master (Model: R-L10)

- Energy Saving

- Lightweight

The S/R Machine (R-L10) is a stacker crane that stores and retrieves pallets, up to 1 ton, into racks up to 15 meters. By making the frame lightweight and adopting premium efficiency motors , energy consumption was reduced 8% compared to standard models. The frame structure was also redesigned and the amount of wiring was reduced, leading to a 10% decrease in the number of parts.

Bolt-up Rack (Model: DC100)

- Lightweight

- CO2 Reduction

The Bolt-up Rack, which uses rivets and bolts to hold parts together, is used mainly as storage racks for automated warehouses. By remodeling the columns, the rack can now be installed in high-rise automated warehouses, which were traditionally welded structures, decreasing weight by 10%. In addition, by not welding, energy used during fabrication was reduced by 30%. In addition, shipping can now be done with the brackets removed, decreasing the number of trucks used and emission of CO2 by about 60%.

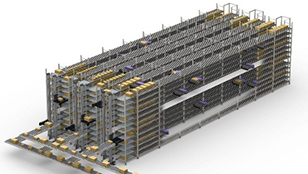

Mini load AS/RS - Shuttle Rack (Model: SRS-M)

- Resource Saving

- Lightweight

The Shuttle Rack is a mini load AS/RS that operates with a vehicle on each rack level. The system stores and retrieves containers and cardboard boxes at high speeds and is used for picking or sorting for shipping. Thanks to a major redesign, the shuttles are now 36% lighter than before. This helps to reduce electricity consumption.

AS/RS for long objects

- Energy Saving

- Lightweight

An AS/RS for storing long objects such as steel beams and timber. Using a customized lightweight pallet, the materials are transferred and stored lengthwise to realize a more lightweight system. The crane incorporates a push-pull method for transferring materials to minimize the moments created during transfers and reducing crane weight by 15%. In addition, by using resin that is applied onto the rack's beams to support the pallets at points, the system weight was reduced by 60% compared to traditional systems. Through these efforts, not only was energy consumption reduced, the environmental impact from manufacturing the system was also decreased.

Transport system - Motor Roller Conveyor

- Energy Saving

- Lightweight

- Low Noise

The Motor Roller Conveyor is ideal for conveying containers and cardboard boxes. Energy consumption is reduced by about 20% by placing rollers that contain highly efficient brushless motors at intervals and activating the motors at the necessary locations when needed. The system is also lightweight, as the number of parts has been decreased. In addition, the system does not use an air supply and essentially produces no noise, improving the work environment.

Cleanroom

Power supply unit for the wireless power supply system HID “HID4-BA”

- Energy Saving

- CO2 Reduction

- Lightweight

The power supply unit for the wireless power supply system HID (High Efficiency Inductive Power Distribution Technology) is an inverter that produces a high-frequency electrical current. The number of components has been reduced from the previous model through improvements to current controllability, and revisions were made to the magnetic materials to achieve a 12% reduction in weight as well as 5% reductions in power consumption and CO2 emissions.

Cleanroom transport system - Clean Space Carrier (Model: CSC/D8050MⅡ)

- Energy Saving

- CO2 Reduction

- Lightweight

This overhead monorail system is designed for LED panel cleanrooms. By revising the number of parts and simplifying their shapes, the system has been made 11% lighter and uses 42% fewer parts. This enables a 12% improvement in both CO2 emissions and waste according to the LCA (Life Cycle Assessment) impact evaluation. In addition, its lighter weight means 15% better linear acceleration and 12% better curve speed, improving its transportation abilities.

10G FPD cassette transporting system

- Energy Saving

- CO2 Reduction

- Lightweight

This system transports glass cassettes in 10G flat panel display (FPD) production lines. The structure of the conventional model was overhauled, and the number of parts was reduced by 10% while maintaining performance, the weight was reduced by 17%, power consumption was reduced by 28% and CO2 emissions were reduced by 27%. In addition, by changing the rail construction, the turnaround time was reduced as was the environmental impact during installation.

Green HID Inductive Wire 500 m

- Energy Saving

- Recyclable

This product expands the power supply range of the non-contact power supply system HID used in transport systems for semiconductor manufacturing cleanrooms. Improving the distribution board enabled a greater power supply capacity of 1.5 times by setting the inductive wire to 500 m, which is longer than the conventional model. Fewer panels are needed, and power consumption is reduced accordingly.

Cleanroom equipment - Mechanical Centering System

- Energy Saving

- Lightweight

The Mechanical Centering System serves to correct the position of the transfer cassette that has been lowered by a crane in front of the glass processing equipment. It is designed for use in flat-panel display production plants with automated warehousing. The positioning unit is driven mechanically by a compressed spring system that eliminates the need for motors or compressors. As a result, power consumption is reduced by 93%, parts count by 22% and weight by 41%.

Cleanroom transport system - Clean Space Carrier (Model: CSC/D6000MⅡ)

- Energy Saving

- Lightweight

The Clean Space Carrier is an overhead monorail system used in cleanrooms for the production of flat-panel displays. Compared to standard systems, the carrier speed was increased from 120 m/min to 180 m/min, a 50% increase. Acceleration was also increased 30% from 0.06G to 0.08G and deceleration was increased 150% from 0.06G to 0.15G. These improvements led to a decrease in the number of carriers needed in a system. In addition, the carrier increased energy efficiency by using energy produced during deceleration. These efforts led to a 16% decrease in energy consumption and 43% decrease in waste.

Cleanroom transport system - Cleanway (Model: CLW-08v2)

- Energy Saving

The Cleanway is a cleanroom transport system for semiconductor factories. In addition to decreasing weight compared to conventional models, the motor control was upgraded, increasing travel speeds from 200 m/min to 300 m/min. By increasing the capabilities of the system, the number of carriers is reduced, decreasing energy consumption and waste by 5%.

Cleanroom transport/storage system - MMHS (Matrix Material Handling System)

- Energy Saving

- Lightweight

The MMHS combines transporting and storing functions and makes effective uses of ceiling space in a cleanroom. This decreases power consumption compared to conventional systems that separate the transport and storage functions. Transfer points can be moved flexibly, which cuts the number of parts replaced during layout changes, making the system highly reusable.

Cleanroom transport system - Clean Space Carrier (Model: CSC/D-5500M)

- Energy Saving

- Lightweight

Overhead monorail system used in cleanrooms for the production of flat-panel displays. The Clean Space Carrier, which transports flat-panel displays, moves 50% faster than conventional systems by optimizing the rotational speed of motors with improved speed drive controls, increasing the transport capacity. This enables a reduction in the number of carriers, which in turn decreases the amount of energy used. In addition, the efficiency of the HID non-contact power supply system was improved, leading to a total of 16% reduced power consumption.

Cleanroom storage system - Clean Stocker (Model: CLS/D-6000HS, D-8050, D-8050L)

- Energy Saving

- Recyclable

- Lightweight

A large number of the Clean Stocker storage systems have been used for cleanrooms, a dust-free environment where flat-panel displays are manufactured. We enhanced energy conservation by upgrading the HID non-contact power supply system, with the aim of significantly reducing overall power consumption, while adding a regenerative charging capability. As stacker cranes require a tiny but constant trickle of power in standby mode, the upgraded Clean Stockers use the regenerated power to further save energy.

Automotive

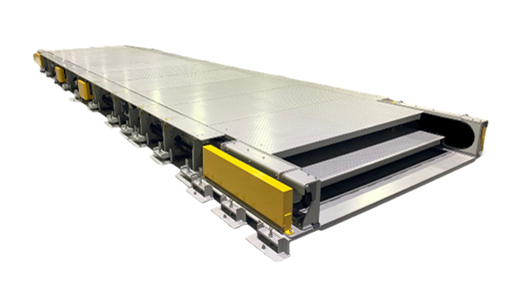

Heavy-duty, low-profile Slat Conveyor

- Energy Saving

- CO2 Reduction

- Lightweight

This is a conveyor system for completed vehicle inspection lines in automobile plants. Installed on the floor, the system can be adapted with relative ease to changes in the number of processes. The load capacity has been improved compared to the previous product, and it is also capable of transporting electric automobiles such as BEVs and PHEVs. In addition, by simplifying the slat plate structure from that of the previous product, the number of parts has been reduced by 3%, the product weight by 6%, CO2 emissions by 7%, and power consumption by 8%.

Distributed HID power supply system - D-HID

- Energy Saving

- CO2 Reduction

- Lightweight

D-HID is a small, low-capacity HID power supply system for point power supplying. Power supply efficiency is improved through a distributed installation at the points that require power, helping to save energy. Compared to previous HID power supply systems, it reduces power consumption and CO2 emissions by 30%, the number of parts by 6%, and product weight by 57%. In addition, it can flexibly respond to the addition or relocation of supply points.

Drive-through truck station - TRTS

- CO2 Reduction

This drive-through truck station system automatically loads and unloads trucks. Trucks can be loaded/unloaded without the use of a forklift, thus reducing the workload for the driver. It reduces the wait time for trucks significantly—from the normal 40 minutes down to 10 minutes. This system also improves the operating rate by optimizing the number of trucks and drivers required.

Standard controller for the Flexible Drive System - FDC

- Energy Saving

- Lightweight

- Long Life

Daifuku updated the controllers used on the Flexible Drive System. In addition to its original functions, a review of the model’s structure resulted in the optimizing of the drive system, reduced wiring, and reduced size and weight. Power consumption was also reduced by 11%, parts count by 47% and product weight by 43%. In addition, use of non-contact parts to extend its service life is increasing.

Tablet control panel for automotive production lines

- Energy Saving

- Lightweight

A tablet computer-type control panel for automobile production line transport systems has been added to the product lineup. The tablets, which allow both monitoring and operational control, are only 1/6 the size and 1/3 the weight of fixed control panels and use 70% less energy.

Skillet conveyor with lifting device - Scissor lift

- Energy Saving

- Lightweight

This trolley lift system uses a newly developed drive unit. The weight of the lift mechanism is 45% lower than with earlier models, and power consumption is reduced accordingly. Simple construction means that 43% fewer parts are needed, thereby contributing to the conservation of resources.

Chainless conveyor system - Flexible Drive System (Model: FDS-FL15)

- Energy Saving

- Lightweight

With the previous lineup of floor type flexible drive systems, the smallest model was rated for 500 kg. We have now added a 150 kg transport model suitable for lightweight objects such as bumpers and doors. By reducing the capacity of the friction drive motor, power consumption when transporting objects with 150 kg or less has been reduced by about 40% compared to conventional systems. In addition, the structure of rails and trolleys has been drastically redesigned for a weight reduction by 45%, which also helps to conserve resources.

Temporary storage and sortation system - SPDR

- Energy Saving

- Lightweight

The SPDR (pronounced “spider”) stores and sorts a variety of cases used in parts logistics. As it does not use racks like conventional AS/RS, it can effectively be applied in limited spaces, contributing to resource saving. In addition to freely handling stacked cases, the system efficiently picks stacked cases and was made lightweight, making it an energy efficient system. By using a transmission belt to move, the system operates quietly, improving the work environment, and is easy to maintain.

Pallet-type conveyor system - Flexible Drive System (Model: FDS-FLP, load bar turn)

- Energy Saving

- Lightweight

A load bar turn was incorporated into the Flexible Drive System (FDS), allowing the carriers to switch directions efficiently. The FDS is used to convey vehicle bodies on assembly lines and can be ridden by workers as they work on the vehicle. The carrier was split into three sections and are joined with a load bar that has an articulating mechanism. The carrier is able to separate and turn, looking like an open fan, eliminating the need for a turn table. This greatly reduced the required energy, weight and the number of parts. In addition, the carriers can be completely separated to be shipped, increasing transportation efficiency.

Power assisting system - ECO POWER ASSIST

- Energy Saving

The ECO POWER ASSIST system reuses the energy generated from the deceleration of motors and then temporarily stored in condensers, which are storage-effective and befitted for rapid charge/discharges. By incorporating this system into lifts and shuttle-type vehicles, the system cuts energy consumption by up to 28%.

Automobile paint line system - E-DIP

- Energy Saving

- Recyclable

Unlike conventional chain conveyor systems, the E-DIP carrier flexibly adjusts the vehicle body angle while immersing and removing it from the dipping tank. In doing so, the E-DIP improves the coating quality, reduces liquid lost from the tank, and helps prevent liquid waste due to inadvertent mixing with other liquids. The E-DIP also enables smaller tanks, which shortens conveyor lines, and actively uses reusable materials.

Car wash machines and related products

One-way drive-through car wash machine - Treus (Model: TE7000)

- Energy Saving

- Long Life

- Water Saving

The Treus is a drive-through car wash machine for self-service stations. Its standout features are the use of a touch screen control panel with color, and the attachment of remote cameras. The machine has an online connection to a call center, which can provide remote monitoring and support by using the attached cameras. Environmentally, reducing the car wash course by one pass saves time and cuts water usage by 10% and electricity usage by 3%.

One-way drive-through car wash machine - Twinfect Riscia (Model: TFR200)

- Energy Saving

- Long Life

The Twinfect Riscia is a drive-through car wash system for self-service stations. In addition to the quick-wash and high-performance drying functions of the previous model, this model has a large 15 LCD touch-screen control panel. Moreover, it enables cashless payment options, such as traffic e-money, QR code, and credit card. Visual clarity and ease-of-use have also been improved. In terms of eco-friendliness, energy consumption can be reduced by changing the run speed, but without lowering the performance of the drying process in water-repellant car washing.

Space-saving gate-type car wash machine - Zechs

- Energy Saving

- Long Life

- Water Saving

The Zechs adds a sixth brush, front side brush, which targets the rear and rear sides of the vehicle, reducing the distance the brushes needs to move. By reducing materials compared to conventional models and eliminating the need for a transport track, we achieved a CO2 emissions reduction of 15% and an energy consumption reduction of 14%.

Tunnel-type car wash machine - Magic Thru (Model: MT2260)

- Energy Saving

- Long Life

- Water Saving

Our world-leading expertise in roller conveyor technology refined over the years ensures the industry’s highest throughput combined with outstanding washing and drying performance. In terms of environmental friendliness, we ensure significantly better corrosion and weather resistance by using highly corrosion-resistant galvanized steel sheets. The system consumes less power and water, and supports the use of environmentally safe liquids.

Large-vehicle car wash machine - Camion Custom (Model: CN8100)

- Energy Saving

- Long Life

- Water Saving

The Camion Custom system features vehicle height sensors and optimized brush control to achieve an industry-leading washing time of only four minutes for a 10-ton truck. Improved operation convenience and quicker washing significantly reduce the load of the driver. The system consumes less power and water, and supports the use of environmentally safe liquids.

Gate-type car wash machine - GSPECT

- Energy Saving

- Lightweight

- Water Saving

The GSPECT, an environmentally friendly gate-type car wash machine, uses only 41 liters of water per vehicle at regular operating speeds while maintaining the same cleaning capabilities. Also, by redesigning the entire machine, the size of the machine was reduced as well as the rail length, which was shortened by 0.5 meters compared to normal machines to 7.8 meters.

Electronic products (Contec Co., Ltd)

Embedded computer (Model: EPC-C5000)

- Energy Saving

- Resource Saving

This industrial embedded computer features high performance in a compact design. In addition to a wide range of interfaces including VGA, HDMI, DisplayPort, USB 3.2, LAN, and serial ports, it is equipped with a PCI-Express (x16) 1 slot and can be fitted with a graphics board. By reviewing the expansion structure and packaging format as well as adopting a new-generation CPU, the number of parts has been reduced by 38%, and it uses 38% less packaging and 13% less electricity.

Box computer (Model: BX-M210-J2311)

- Energy Saving

- Lightweight

This industrial box computer offers numerous features in a small volume. In addition to standard functions, it is equipped with 32/32 isolated inputs/outputs and an easily convertible RS232/422/485 interface. By optimizing the layout of board-mounted components and adopting a new-generation CPU, functions that previously required a large space for mounting expansion cards have been consolidated. In addition, the case has been optimized through schematic cable routing, and by controlling heat dissipation, we were able to omit the fan and achieve a wide temperature range that enables operation in harsh environments. As a result, this model is 61% lighter, 72% smaller in volume, and consumes 52% less electricity than previous products.

Industrial edge AI computer (Model: DX-U1220-3E0212)

- Energy Saving

- Lightweight

This is an industrial computer suitable for AI inference processing with the NVIDIA® Jetson Xavier™ NX module. It offers flexible installation and durability against the environmental conditions in which it will be used. It also comes with high-capacity NVMe storage as a standard feature, allowing for worry-free use in practical applications. Regarding the software environment, the JetPack SDK for each version of the product is available on the website, and applications can be run with the version used in the developer kit. The product has been designed to be more sophisticated and compact, and it is 12.7% lighter and uses 8.6% less electricity than previous products.

Box computer (Model: BX-T3000)

- Energy Saving

- Lightweight

- Resource Saving

This industrial box computer offers both a slim design and a wide range of operating temperatures (-20°C to 60°C). It also offers a wide range of interfaces, including DisplayPort, USB 3.2, and LAN, and there are models that support wireless LAN and Bluetooth® as well. The ease of connecting it with digital devices makes it the perfect IoT gateway terminal. By using a case which doubles as a heatsink, revising the packaging format, and using a new generation CPU, the computer uses 78% less packaging, 26% less electricity, and is 35% lighter.

Raspberry Pi expansion board (Model: CPI-DIO-0808L)

- Energy Saving

- Resource Saving

This expansion board is designed to increase the digital input/output interfaces for Raspberry Pi on single-board computers. With eight photocoupler isolated inputs (supporting current sink/source output) and isolated outputs (current sink type), up to eight expansion boards can be connected simultaneously to a single Raspberry Pi device. By using a DC/DC converter, the board cuts electricity consumption by 24% compared to competing products. It also uses 80% less packing by weight.

Battery-driven BLE-LTE converter supporting IP67 (Model: CPSB-BTM1-S011)

- Energy Saving

- Lightweight

This BLE-LTE converter collects a range of sensor data, including gas pressure, water pressure, temperature, humidity, door closure status, and more via Bluetooth®, and sends this data to a cloud server via LTE. Graphing this data will visualize the status of factory facilities and infrastructure such as gas and waterworks. By improving the electrical circuits and software specifications, electricity consumption has been cut by 86% compared to competing products. The number of on-board batteries has also been reduced, dropping weight by 16%.

Box computer (Model: BX-U200)

- Energy Saving

- Lightweight

- Resource Saving

This small, lightweight industrial box computer reduces the number of peripheral connection ports to the minimum required. Mounted IC parts have been integrated into one and metal parts and packaging have been made one-piece, achieving a 43% reduction in energy consumption, a 53% reduction in weight, and a 56% reduction in packaging materials.

Box computer (Model: BX-M1500)

- Energy Saving

- Lightweight

This industrial box computer uses a high-performance CPU that operates without a fan. It uses a TDP35W CPU and the use of heat-sink technology eliminates rotating parts. The fan has thus been eliminated—also eliminating the need to eventually replace it—and the case size has been reduced, thereby lowering power consumption by 42% and weight by 31% compared with the previous model.

Lamination signal measuring unit (Model: CPS-PAV-AE01-JP)

- Energy Saving

- Resource Saving

This gauging unit uses a light sensor to detect the illumination status of the lamination signal lamp and sends the data via a low-energy consumption wireless signal. Aggregating the data allows the operating status of equipment to be visualized. The use of a low-energy consumption wireless signal and reduced start-up time saves on power use, reducing energy consumption by 83% compared to that of competing products. Additionally, the packaging material has been changed to be 2.5% lighter, thereby contributing to resource conservation.

Insulated analog input unit (Model: AI-1608VIN-USB)

- Energy Saving

- Resource Saving

This is a USB 2.0 compatible unit with expanded capabilities for analog signal input from PC USB ports. Along with increasing the number of I/O points compared to conventional units, adjustments made to the parts and circuit configuration reduced power consumption by 21%. In addition, a 14% reduction of packing material weight contributes to resource conservation.

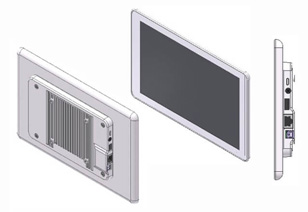

Panel computer (Model: PT-970W10WA)

- Energy Saving

- Lightweight

An LCD integrated panel computer equipped with a 10.1-inch (WXGA 1280×800) touch panel display. By carefully selecting the installed interface and limiting it to the minimum required features such as 1000 BASE-T, USB 2.0 and audio, power consumption was reduced by 46%, weight by 81%, and the number of parts by 59%.

Box computer (Model: BX-T1000)

- Energy Saving

- Lightweight

This compact box computer uses the 7th generation Intel® Core™ processor series for high processing capacity. The parts and circuit configuration have been overhauled for thorough energy savings, and the casing was redesigned from the ground up for a power consumption reduction of 27% and a design that is 26% lighter.

High-speed GPIB communication micro converter (Model: GPIB-FL2-USB)

- Energy Saving

- Lightweight

This micro converter has a 2KB transmission/reception buffer memory that reduces the CPU load and converts a USB port on a computer to a GPIB communication port conforming to IEEE 488.2. Optimized circuit design and component materials result in a 13% lower power consumption and 13% fewer parts compared to earlier models.

Factory automation computer (Model: VPC-700)

- Energy Saving

- Lightweight

This compact, high-performance factory automation computer uses the 6th Generation Intel® Core™ processor series. The CPU capacity has been boosted 1.8 times, and the product specifications and structure were redesigned for a power consumption reduction of 7% and a design that is 23% lighter compared to earlier models.

M2M Controller CONPROSYS nano (Model: CPSN-MCB271-S1-041)

- Energy Saving

- Lightweight

- Resource Saving

The affordably priced terminal enhances system design flexibility by freely allowing configuration of the necessary signal input and output functions. This makes it easy to build a network-based remote monitoring system using a wide range of computers as a host. Simple construction and optimized functionality result in 52% lower weight, 35% lower power consumption, and 64% less packing material as compared to earlier models.

RS-232C communication unit (Model: COM-4CN-USB)

- Energy Saving

- Lightweight

- Resource Saving

Rated for operation over a wide temperature range (-20℃ to +60℃), this USB connection unit makes it possible to add four serial ports to a computer. Optimized circuit design and more compact enclosure result in 47% lower volume, 38% lower weight, 55% lower power consumption, and 68% less packing material compared to earlier models.

Ruggedized switching hub (Model: SH-8008F)

- Energy Saving

- Lightweight

- Resource Saving

This highly compact switching hub supports operation over a wide temperature range from -20℃ to +60℃ and is mountable in a 35 mm DIN rail. Thanks to circuit optimization, the unit consumes 45% less power than the predecessor product, and the improved heat dissipation design enables more compact dimensions (32% reduction). Redesigned packaging results in a reduction of 52% by volume and 24% by weight and thereby contributes to the conservation of resources.

Solar power generation data measurement and display device - SolarView Battery (Model: SV-BPX-MC310)

- Energy Saving

- Lightweight

- Resource Saving

This compact power-saving device is designed for measurement and information display in systems that combine solar cells and lithium ion batteries. Unlike conventional systems that are configured with a general-purpose computer, the new product utilizes a dedicated all-in-one measurement controller, realizing an amazing 91% reduction in power usage, 81% weight reduction, and 96% reduction in packaging material.

Stack-type controller - EtherCAT (Model: CPS-ECS341-1-011)

- Energy Saving

- Lightweight

This Slave Module realizes high-speed real-time operation in accordance with EtherCAT, a global standard for real-time communications. It provides a dedicated high-speed expansion bus that supports real-time control of a wide range of I/O combinations (including digital and analog I/O). The circuitry has been optimized for EtherCAT functionality, resulting in 41% lower power consumption than with conventional systems, along with a 30% weight reduction.

Compact box type computer (Model: BX-320)

- Energy Saving

- Lightweight

- Resource Saving

The BX-320 is a small, high-performance industrial PC, which can fit on the palm of a hand, with an Intel Quad Core Atom processor that can be installed on a 35 mm DIN rail. For cooling efficiency, the heat sink and other features were structured with the optimal design, decreasing weight by 14%. In addition, energy consumption was decreased by 2%, despite having a high-speed CPU, with total decrease of 11% if increased power consumption by the CPU is not included. Packaging was also redesigned, cutting packaging volume by 69% and weight by 33%.

M2M Controller (Model: CPS-MC341-ADSC1-111)

- Energy Saving

- Lightweight

The M2M Controller is a compact device for remote monitoring and controls that combines a variety of I/O functions, including digital and analog input/output. By combining the I/O functions, which conventionally required multiple I/O devices for one system, electric consumption was decreased by 34% and weight was reduced by 37%.

Solar power measurement display system - SolarView Compact (Model: SV-CPT-MC310)

- Energy Saving

- Lightweight

- Resource Saving

The SolarView Compact measures solar power generation and displays and saves data on a small console. By switching from a Windows-based computer to a specialized measuring device based on a microcomputer, energy consumption was cut by 99% and weight was reduced by 91%.