Message from the CEO

Under our management philosophy, Automation that Inspires, we will contribute to the realization of a sustainable society through our business activities.

Message from the Sustainability Officer

We will contribute to the realization of a sustainable society by creating the economic and social value we must aim for based on our long-term vision.

Daifuku’s Value Creation

We are enhancing the competitive advantage of our customers while contributing to the advancement of society.

View details

Contributing to the Environment and Society with Our Products

We are accelerating our initiatives focused on the future and contribute to solving environmental and social issues through our products.

View details

Daifuku’s Sustainability

Under our long-term vision Driving Innovative Impact 2030, we strive to create both social and economic value.

View detailsESG Initiatives

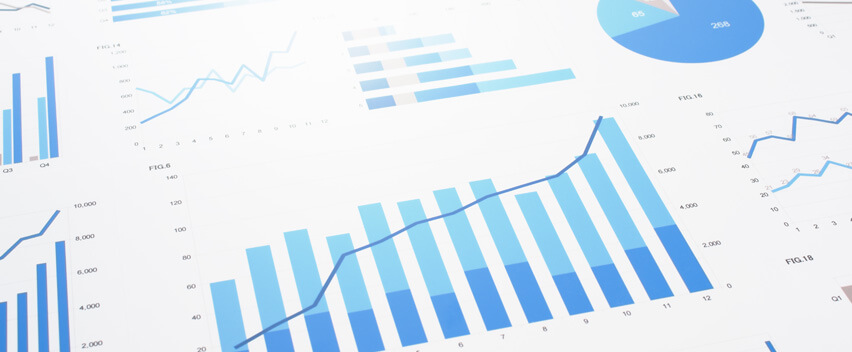

ESG Data

Comprehensive overview of environmental, social, and governance data for the Daifuku Group.

Evaluation from Outside the Company

Explains the evaluation and ratings of various activities and initiatives of the Daifuku Group by independent third party organizations.

Sustainability Report

The sustainability information on this website is also available in PDF format.