Contributing to the Environment and Society with Our Products

Based on our long-term vision, Driving Innovative Impact 2030, the Daifuku Group will accelerate our initiatives focused on the future and contribute to solving environmental and social issues through our products.

Sustainability Performance Assessments of Products

In fiscal 2024, we began conducting sustainability performance assessments to evaluate the environmental and social value of our products and systems. From fiscal 2012 to fiscal 2022, we conducted environmental performance assessments of our products under the Daifuku Eco-Products Certification Program; however, going forward, we will evaluate our products from a broader perspective that includes consideration for the environment as well as contributions to customers and society.

We will continue to conduct environmental impact assessments for all our products using an LCA (Life Cycle Assessment) method. By fully grasping the environmental impact of our products throughout their entire life cycle, we will strive to further enhance environmentally conscious product design.

Main points of evaluation

| Environmental value |

|

|---|---|

|

|

| Social value |

|

|

|

|

|

|

|

|

Efforts for Energy and Resource Conservation in Products

Our Group’s products contribute extensively to factory automation in general industry, semiconductors, and automobiles, as well as to labor saving in logistics centers and more efficient airport operations. We consider the minimization of energy consumption during operations and of the resources used in our products to be an important initiative, and we are working on utilizing creative ideas and applying various technologies from the design stage.

Examples of initiatives for energy conservation

Utilization of regenerative power

- In automatic warehouses and transport systems, utilize regenerative converters to harness the regenerative energy produced during deceleration and descent and feed it into the power supply of other machines, equipment, and devices

- Regenerate the deceleration energy of the motors in Automated Guided Vehicles (AGVs) and recharge the batteries for effective use

Installation of energy-saving functions

- Equip AGVs, conveyors, and sorters with a function that turns off the power during standby

- Support the optimization of machine operation and the energy-saving activities of customers through the visualization of energy consumption using monitors

- Equip transport systems with a function to equalize power demand

- Reduce the amount of energy consumed during car washes by installing an ECO mode

Use of motors and inverters

- Install power generation motors on sorting vehicles to improve the efficiency of power supply

- Use high-efficiency motors in transport systems or install them as standard

- Reduce energy consumption by using inverters in car washes

AI-based optimization

- Optimize the routes and sequences of transport systems using AI technology (enables the same amount of transport to be carried out with fewer AGVs)

Weight reduction

- Implement lightweight designs through strength analyses

- Consolidate the ICs (integrated circuits) on circuit boards to make electronic products lighter and more compact

Other

- Reduce energy consumption by adopting new generation CPUs in electronic products

- Install thermostats in car washes to minimize the use of heaters in cold regions

- Utilize simulations to reduce the number of test runs on actual equipment, resulting in reduced energy consumption

Examples of initiatives for resource conservation

Reduction of materials

- Implement lightweight designs through strength analyses

- Reduce the number of parts by consolidating ICs (integrated circuits) and using innovative sheet metal structures

- Switch from product description CD-ROMs and paper media to web downloads

Extended service life

- Research materials to improve the durability of traveling wheels

- Utilize resin or corrosion-resistant materials to enhance rust resistance

- Create designs that eliminate rotating bodies such as fans and hard disk drives

- Avoid using condensers or use extended-life condensers

Virtual engineering

- Reduce the number of parts by utilizing 3D models

- Reduce the number of parts used in prototypes by utilizing virtual engineering such as capability simulations, virtual emulations, and welding analyses

Environmentally friendly materials

- Utilize recycled and biomass resins

- Utilize environmentally friendly liquid detergent in car washes

- Utilize RoHS2-compliant parts

- Utilize cardboard as a packing material

Product Overview

Manufacturing and distribution systems

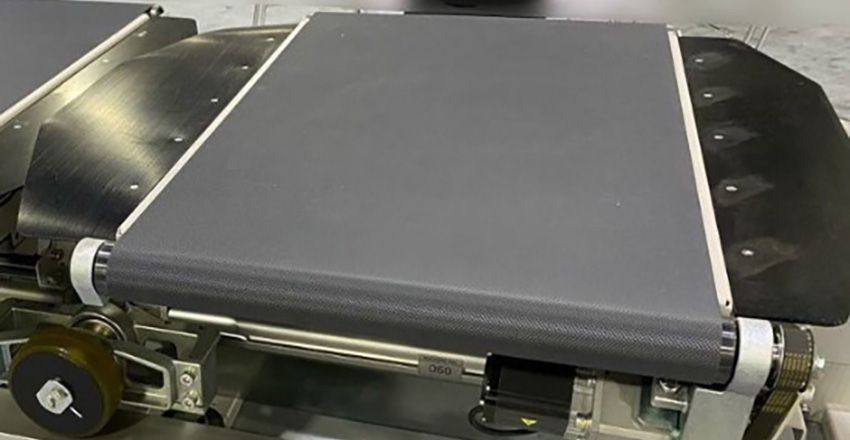

Cross-Belt Sorter

The Cross-Belt Sorter is a system that sorts items at high speed by rotating the belts on each of the connected carts as they travel along the rails. It is mainly used in e-commerce logistics, where a large volume of items of various sizes and shapes must be sorted in a short period of time, and it contributes to improving work efficiency and alleviating labor shortages. Since each cart operates independently, a malfunction in one does not require shutting down the entire system, allowing operations at logistics sites to continue with minimal disruption. By supplying power from a power generation motor mounted on the carts, we have reduced their weight, lowered energy consumption, and lowered costs.

- Environmental value

-

- Compared to the non-contact power supply HID* model, this model reduces energy consumption by 3.5% and CO2 emissions by 8.1%

- Social value

-

- Compared to the non-contact power supply HID* model, this model features lower costs

- A quiet design contributes to an improved working environment

- *HID is an abbreviation for High Efficiency Inductive Power Distribution Technology

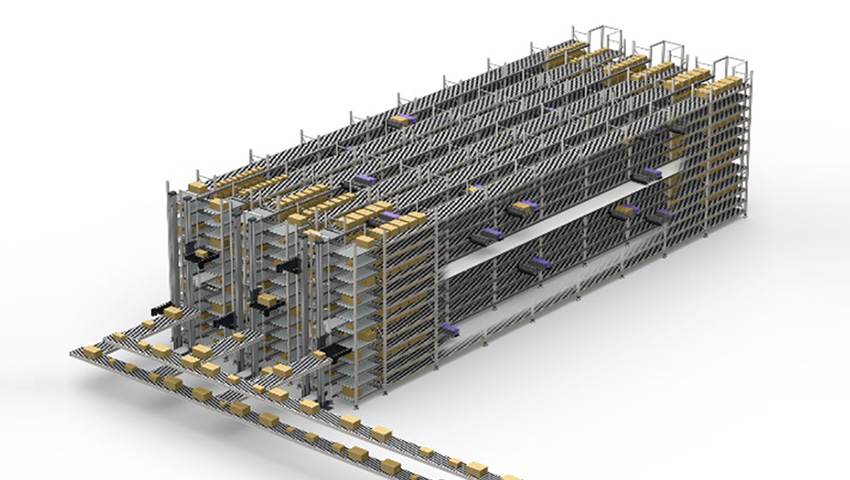

Shuttle Rack (SRS-M Double-Deep)

The Shuttle Rack M is a high-capacity automated warehouse system that uses carts on each level of the rack to provide both temporary storage and sorting functions. As it can store and sort large quantities of goods within limited spaces, it is mainly used in e-commerce logistics, which handles a wide variety of products in small lots. It is also used in retail, manufacturing, transportation, and agriculture, contributing to efficient sorting, storage, and picking operations. The carts are now capable of storing two items depth-wise on the shelf, allowing for more efficient and higher-density storage.

- Environmental value

-

- Both energy consumption and CO2 emissions have been reduced by over 50% in comparison to a similar product*

- Social value

-

- This model has three times the transport capacity compared to a similar product*

- The space-saving design makes effective use of the space in logistics sites

- * Mini Load AS/RS (R-F3)

Cleanroom production line systems

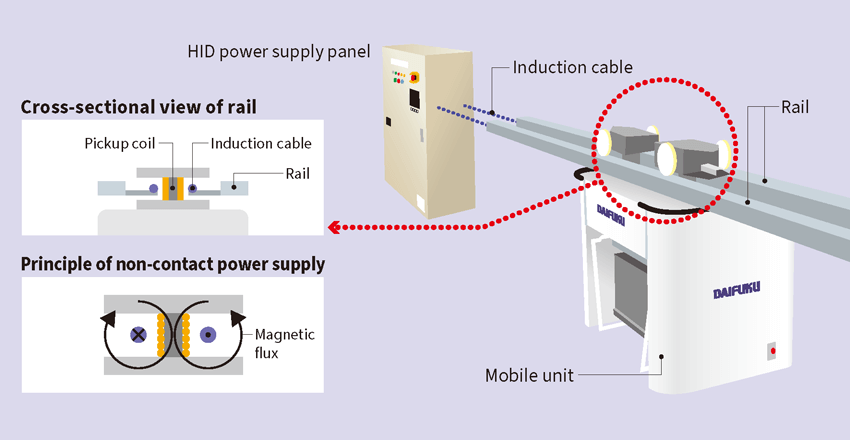

Wireless power supply system HID power supply unit HID4-BA

The wireless power supply system HID power supply unit HID4-BA is a power supply system that provides non-contact electric power. Unlike power supplied through cables, it does not generate dust from friction and is therefore used in many semiconductor manufacturing lines and liquid crystal manufacturing facilities where a high level of cleanliness is required. Automated transport enables the production of high-quality products at a low cost and in a shorter timeframe. Additionally, the non-contact design prevents wear and tear, allowing for stable, long-term power supply and a significant reduction of maintenance costs.

Please enlarge the screen to view

A high-frequency current is passed through induction cables on the rails, generating magnetic flux around them. This flux is captured by a pickup coil, creating induced electromotive force through electromagnetic induction.

- Environmental value

-

- Reduces the number of parts and the amount of resources used

- Reduces power loss by changing the high-frequency transformer

- Social value

-

- Installation work is made easier by a 12% weight reduction

- Reduction of parts improves maintainability

CLS-51 RM

The CLS-51 RM, a type of Clean Stocker, is a device that is used to temporarily store carriers* during semiconductor production. Utilizing the storage and transport technology that Daifuku has cultivated over the years, this device allows for the accurate and efficient management of carriers in limited spaces. We made a variety of improvements to this product, including reducing the number of masts (columns) from two to one in the rack master section. Reducing the number of parts has resulted in a lighter-weight product and led to reduced energy consumption.

- *Containers for transporting and storing multiple semiconductor wafers and other items.

- Environmental value

-

- Energy consumption and CO2 emissions per transport have been reduced by over 40% compared to similar products*

- 35% reduction in overall weight due to significant reduction of number of parts

- Social value

-

- 30% improvement of transport capability compared to similar products*

- Improved ease of assembly due to reduction of number of parts and weight

- Improved serviceability by changing the drive unit to a simpler structure

- *CLS-50II RM

Automobile production assembly line systems

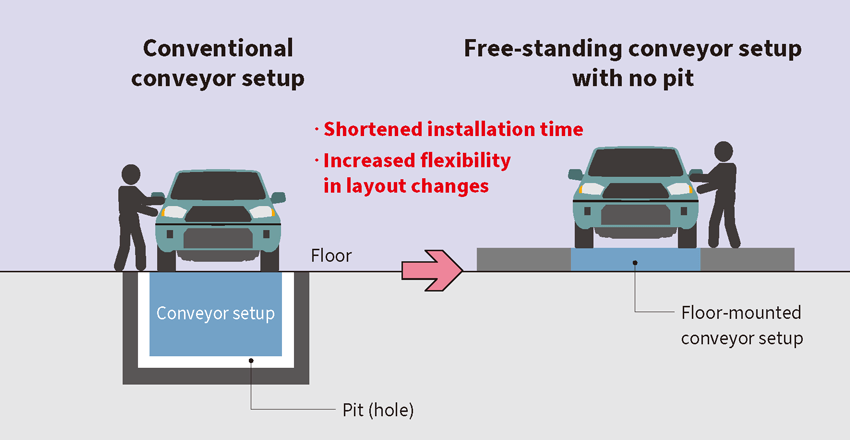

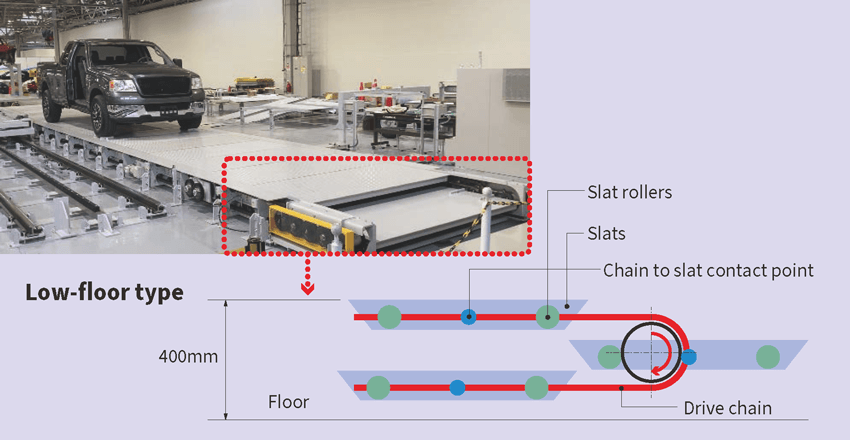

Heavy-duty, low-floor SLAT conveyor

The heavy-duty, low-profile SLAT conveyor is designed for use in the assembly and inspection lines of automobile factories. Unlike conventional models that require a deep pit for installation due to their large drive units, this product features a compact, divided drive unit that allows for a low-floor design. This innovation eliminates the need for pit construction, thereby reducing waste and CO2 emissions during installation. Additionally, by increasing the maximum load capacity and adjusting the combination of rail units, this conveyor system can adapt flexibly to changes in production lines. It is used as a production line to improve efficiency in factories that have significant production variability, such as those that handle both gasoline-powered cars and heavy electric vehicles (EVs).

Please enlarge the screen to view

Please enlarge the screen to view

- Environmental value

-

- An enhanced life span has been achieved by improving the bearings and chains of conventional products

- Reduction of product weight has resulted in an 8% energy consumption reduction

- Social value

-

- Efficiency of installation work has been improved by arranging standardized units

- Reducing the total number of parts by 3% has made assembly work more efficient

- There is no longer any need to enter a pit during maintenance, reducing the work burden and improving safety

Airport technologies

Baggage handling system

The baggage handling system efficiently transports and sorts passengers’ checked baggage at high speeds. It is designed for environments requiring rapid sorting of large volumes of baggage, such as in major airports. Unlike conventional belt conveyor systems, this system prevents damage to items by transporting each item individually on its own tray. By replacing the traditional wide belt with a combination of a narrow belts and rollers, we have successfully reduced the size of the motor. Additionally, by implementing an energy-efficient control system that activates the conveyor only when baggage trays pass through, we have significantly reduced energy consumption. The system reads the RFID chips attached to each tray, allowing for precise tracking of baggage in transit. This not only helps prevent lost baggage, but also reduces the labor and manpower needed to resolve baggage congestion.

- Environmental value

-

- Energy consumption is reduced by approximately 27% compared to conventional products that use belt conveyors

- The overall weight was reduced by 40% by reducing the amount of belts and conveyor frames used

- Social value

-

- World-class transport speed of 600m/min

- A decrease in the frequency of baggage congestion saves labor

- 13% quieter than conventional products, helping to improve the work environment

Car wash machines

Drive-through car wash machine Treus (CMTE7000)

The Treus is a key model of drive-through car wash machine, primarily used at self-service gas stations. By combining brushing and rinsing in a single operation, it reduces the number of back-and-forth movements required for foam car washes from 2.5 to 1.5, leading to shortened car wash times as well as savings on both water and electricity. Additionally, it features the industry’s first Car Wash Smart Support function, enabling real-time communication with the service center and remote monitoring and operation of the machine in case of issues. This innovation eliminates the need to wait for service staff, allowing for quicker problem resolution and reduced downtime, ultimately improving operational efficiency.

- Environmental value

-

- Improved car wash operations and ECO mode settings reduce water usage by 10% and electricity usage by 20%

- By changing the material of the coating agent and piping, the number of clogged pipes is decreased and the frequency of cleaning is reduced to one third

- The Car Wash Smart Support function decreases the number of visits to customers, resulting in reduced CO2 emissions

- Social value

-

- Allows for rapid recovery and improved usability through remote operation

Electronics

BX-T3000

The BX-T3000 is an industrial box computer featuring a power-efficient, high-performance CPU. It delivers excellent calculation and rendering capabilities while maintaining energy efficiency. This unit is commonly used in factory inspection equipment, medical devices, and digital signage terminals on buses and trains. Its compact and lightweight design allows for installation in an area roughly the size of an A5 sheet of paper. With a broad operating temperature range, it can function reliably in harsh outdoor conditions, making it suitable for a variety of environments. Additionally, its design eliminates the need for a cooling fan and features a sealed structure without exhaust ports, which prevents dust and foreign objects from entering and minimizes maintenance and inspection workloads.

- Environmental value

-

- Due to its smaller size, the main unit weighs 35% less than previous products

- 78% reduction of internal packaging materials compared to previous products

- The adoption of a new generation CPU has reduced power consumption by 26% compared to previous products

- Social value

-

- Despite its thin design, the unit combines a broad temperature range (-20°C to 60°C) with high performance, contributing to stable operation in a wide range of fields

Please refer to the following web page for details about products certified under the Daifuku Eco-Products Certification Program, which was in operation from fiscal 2012 through fiscal 2022.