Building a Flexible Production Line with the TRVS; a 6.5-Ton-Load Capacity AGV

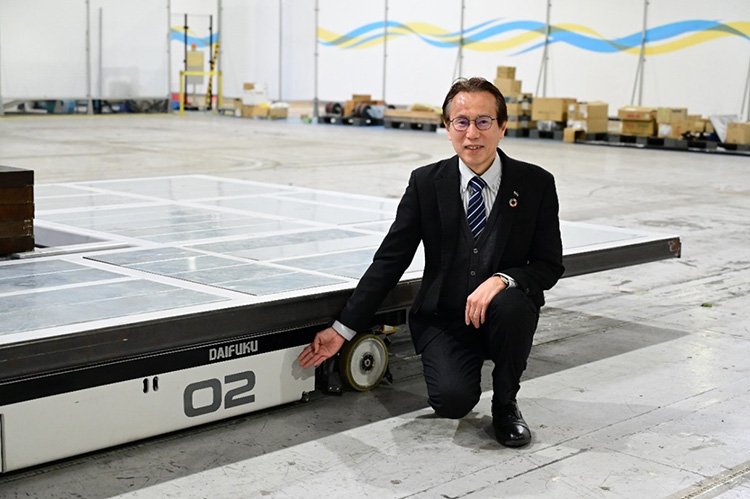

Daifuku is dedicated to supporting sustainable mobility in society by developing next-generation automation systems for vehicle manufacturing. The TRVS automated guided vehicle (AGV), capable of omnidirectional movement and a load capacity of up to 6.5 tons, is a new solution from Daifuku to enable more flexible vehicle production lines. We spoke with Nobuhiro Hayashi, head of the Automotive Division’s Technology Department, about the design and development goals of the TRVS.

What can you tell us about the TRVS?

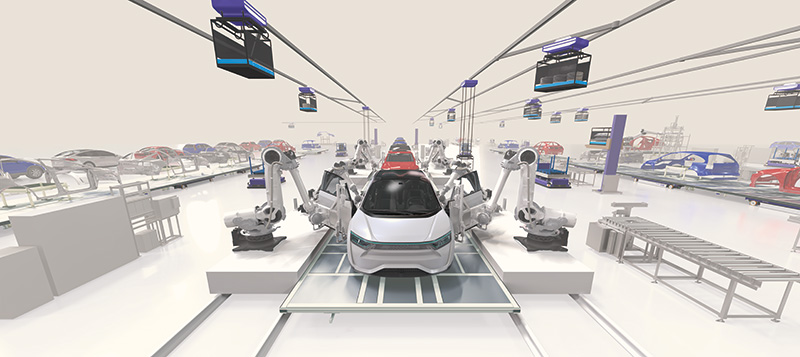

In vehicle production lines, the car body is placed on a large cart that moves slowly along the line. Assembly workers also ride on this cart. As many as 20 carts will be connected and move at fixed intervals. With conventional systems, these carts are powered by a conveyor system in the floor underneath. The TRVS replaces that setup. The TRVS can move in all directions; forward, backward, sideways, and diagonally, as well as make turns and even rotate on the spot, greatly improving line flexibility. In addition, while changing conveyer-based assembly line layouts requires stopping the line and closing the factory for an extended period to restructure, with the TRVS, routes can be updated in just a few days.

Why did you choose to make the TRVS omnidirectional?

With conventional systems, the production line follows a single, unbroken path. Today, it’s common to use the same line for both electric vehicles (EVs) and internal combustion engine (ICE) vehicles. For such a case, ICE models simply pass through the battery installation area and have their engines installed further down the line. But when producing even further variety, such as EVs, ICEs, and fuel cell vehicles (FCVs) on a single line, the process becomes increasingly complex, requiring transport to different, non-shared work areas, and making the production line longer overall. Because the TRVS can move in all directions, it is easier to create more efficient layouts. For example, the TRVS enables branching off to perform specific tasks before rejoining the main line, and it can also be used alongside traditional conveyor systems. This flexibility is one of the greatest advantages of the TRVS.

-

In conventional systems, car body carts are moved via conveyor.

-

AGVs provide a new method for moving the car body cart.

Supporting All Possibilities, Including the Shift to EVs

Is the system mainly intended for overseas markets, where EV adoption is advancing quickly?

There’s certainly potential overseas. But I want to emphasize that the TRVS isn’t just for EVs. EVs are just one of many types of vehicle. Even if types are not being mixed, when producing different models or configurations on the same line, the ability to branch and merge is invaluable. In short, the system is designed to support all kinds of production possibilities.

Were requests for more flexible production lines becoming more common?

Not exactly. Rather than responding to specific requests, we developed the TRVS based on Daifuku’s belief that such a system would become necessary as the automotive industry evolves. This system represents a major shift in production methods, so we don’t expect it to be adopted on every line right away. Nevertheless, automakers are facing tough challenges, and we believe that they will require a solution like the TRVS. In facilities with relatively low production volumes for EVs and FCVs, it may still make sense to modify existing lines for mixed-model production. But there is a point where it will become too difficult to adapt existing setups, and improving efficiency will require a complete change in production methods.

The TRVS uses a slim, elongated design measuring 3 m long, 44 cm wide, and 27.5 cm high.

The TRVS has a slim, ski-like design. How does it manage to move a cart and vehicle body weighing up to 6.5 tons?

The cart has a central wheel, and the TRVS slides under one side to tow the entire cart. If the cart were pulled directly, the wheels might slip, so we added internal springs to increase friction at the contact point. The 6.5-ton capacity was designed with heavier EVs in mind, but it’s more than enough to transport any standard passenger vehicle body all the way to the final line, where the car is nearly complete.

Are there plans to use the TRVS for applications beyond vehicle production lines?

Our initial focus is on automotive use. However, by coordinating two TRVS units, it is possible to move more than 10 tons, and theoretically a single system is capable of coordinating up to 100 units, so we’re also considering future applications for transporting other heavy items, such as steel materials. We believe there’s demand for flexibly moving large, heavy loads in a variety of industries.

Lastly, how is Daifuku approaching technology development in today’s rapidly changing automotive industry?

In the Automotive business, we’re focused on achieving the goals outlined in the Daifuku Group’s long-term vision, Driving Innovative Impact 2030. This means developing transport and automation systems tailored to next-generation vehicle manufacturing. The TRVS is a core part of this effort.

Over the years, we’ve worked closely with automakers—not only by delivering systems but also by performing regular service and modifications. Through this, we’ve analyzed customer needs and used that data to offer high-value-added services. We believe that the strong relationships we’ve built by improving customer satisfaction allow us to identify latent or unarticulated needs and challenges. As the global mobility market continues to rapidly evolve, we will continue creating new value by delivering automation systems that adapt to an ever expanding range of customer needs.