Treus Wide: Daifuku’s Latest Car Wash Machine Redefines Convenience and Quiet

When it comes to self-service car wash machines, customers hope for a quick and hassle-free experience, but narrow entrances and loud brushing noises can make the experience uncomfortable. To address these concerns, Daifuku has introduced the Treus Wide, a new drive-through car wash model designed for smoother entry and quieter operation. What sets the Treus Wide apart is its industry-first integrated pure water system, which significantly reduces drying time and helps achieve a clean, spotless finish. We spoke with Shinji Kanamaru, Manager of the Standard Design team in the Design Department of Daifuku’s Auto Wash Division, about the Treus Wide’s key features and the development process behind it.

The Treus Wide car wash

Can you tell us about the key features of the Treus Wide and how it was developed?

Certainly. The Treus Wide introduces four industry-first innovations. The first is a wider entrance, we expanded it by 20 centimeters to 260 centimeters while maintaining the machine’s original installation footprint.

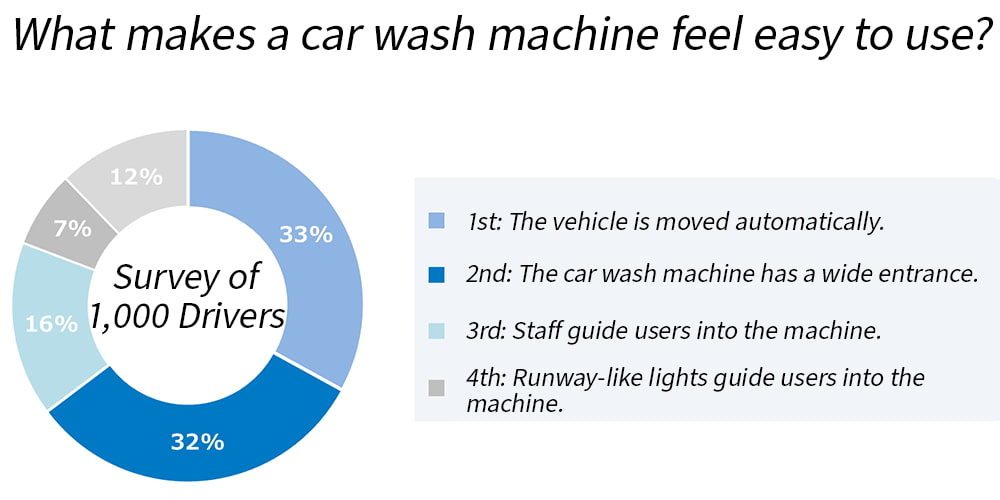

As vehicle dimensions continue to grow, feedback from drivers indicated that it was getting harder to drive into car wash machines. In response, Daifuku Plusmore—the Daifuku Group company responsible for sales and service of Daifuku car wash machines in Japan—conducted a survey in 2024 to better understand how to enhance customer comfort. The survey revealed that a wider entrance was a top priority, guiding our design focus.

Since most new car wash machine installations are replacing existing machines, we knew that space constraints at current sites would be a key factor. That’s why simply enlarging the machine wasn’t enough, if the machine itself became larger, it might not fit in the limited space available at existing sites. Instead, we undertook a complete redesign of the frame structure, enabling a wider entrance without increasing the overall footprint of the machine.

Does the machine’s wider interior offer the same washing and drying performance?

Yes, it does. Expanding the interior naturally shifts the side brushes and drying nozzles farther from the vehicle, which could compromise effectiveness—especially for narrower vehicles like compact cars. To counter this, the Treus Wide comes standard with rocker brushes that focus on cleaning the lower sides of the vehicle, along with adjustable side nozzles to ensure consistent drying.

Brushing Noise Reduced by More Than 10 dB

The brush design looks quite unique.

Yes, that’s our second industry-first innovation: the Ruffle Brush, a brush that delivers the same cleaning power while significantly reducing operational noise. On top of that, it offers durability on par with sponge-type brushes.

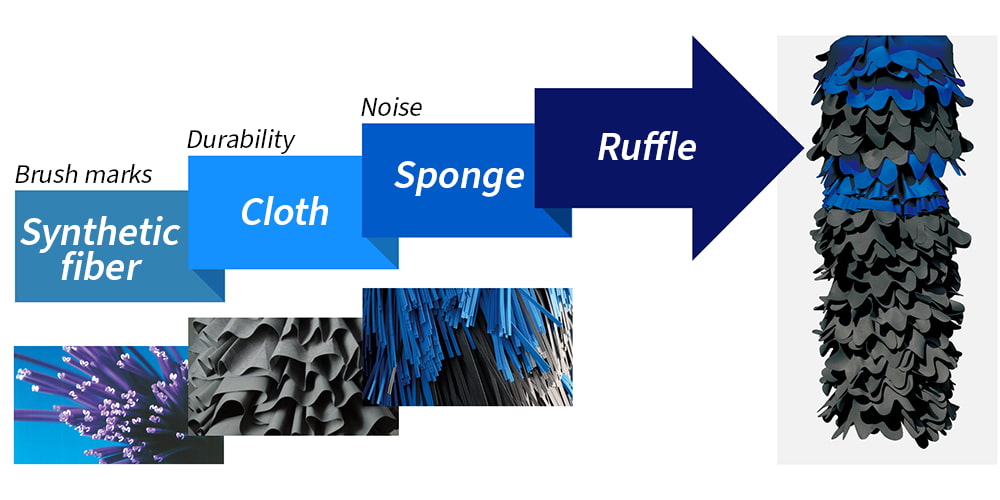

There are three main brush types used in car wash machines: nylon-based synthetic fiber, nonwoven fabric cloth, and sponge—each with their own distinct characteristics. When car wash machines first appeared in the 1960s, synthetic fiber brushes were standard. Back then, the nylon material could sometimes leave marks on the car body. So, over time, they’ve been made softer through improvements like special rubber blends and wavy cross-sectional designs. These marks could be cleaned off, but customers often mistook them for scratches, creating distrust in car wash machines.

Cloth brushes with a broader surface area were developed to fully address the issue. However, due to the nature of the material, these brushes had the drawback of requiring more frequent replacement. The sponge brushes widely used today offer much greater durability but also tend to produce more noise during washing, which some users—especially those unfamiliar with car wash machines—find intimidating.

That’s why, with the Ruffle Brush, we set out to combine the best features of both sponge and cloth brushes. We used a newly developed sponge material and installed it in a way that mimics cloth brush construction. As a result, we successfully reduced brushing noise by more than 10 decibels based on in-house testing.

What were some of the challenges during development?

Before we ultimately landed on the final ruffled design, we explored various shapes, including straight patterns. A key challenge was balancing noise reduction with durability. Thinner brushes reduced noise but compromised durability. We also had to fine-tune the rotation speed of the brush and the amount of pressure applied to different parts of the car to ensure optimal cleaning performance. These adjustments required extensive testing and iteration.

Pure Water System Optimized for Car Wash Machines

What other features set the Treus Wide apart?

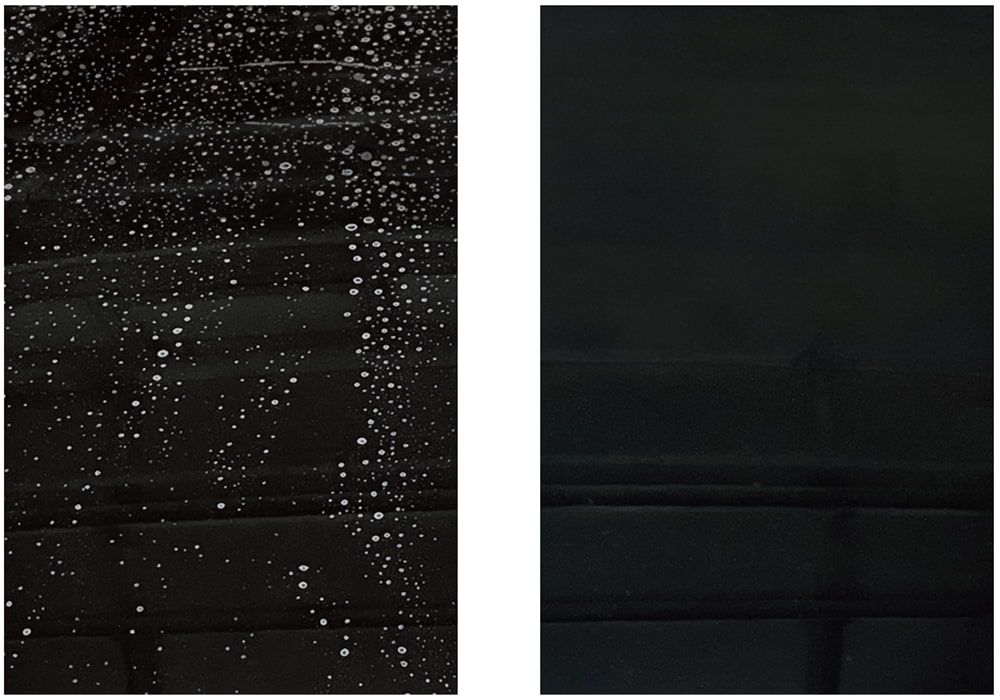

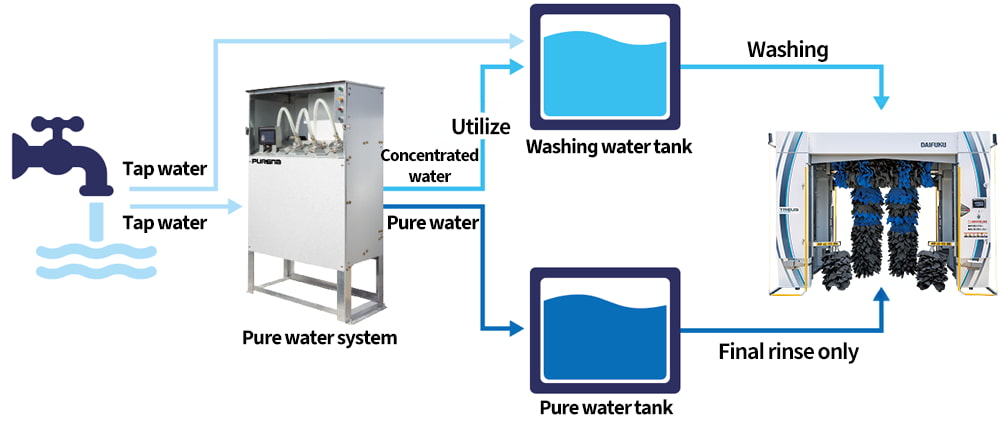

Our third industry-first innovation is our in-house developed pure water system. Pure water is water that has had nearly all minerals and impurities removed, which helps prevent post-wash water spots and significantly reduces the amount of time and effort needed for drying.

Water spots are visible when using tap water while the surface is clean when using pure water.

In conventional car wash machines with off-the-shelf pure water units, the pure water is used throughout the wash process, and the concentrated water—with the impurities from the purification process—is simply discarded. But Daifuku’s system, which was specifically designed for car wash machines, optimizes performance by using pure water only for the final rinse, where it matters most. The concentrated water is recycled; diluted with tap water and utilized in earlier wash stages. After all, there’s no need to use pure water when applying shampoo or other cleaning agents. By reducing the amount of pure water used, we were able to make the unit more compact, lower operating costs, and create a more environmentally friendly system through water reuse.

At first, there was a strong assumption within our team that the concentrated water had to be discarded, and that’s the direction we initially pursued. However, a lot of our customers provided feedback that they didn’t want to waste it, which prompted us to revisit the concept and ultimately arrive at the current solution. We believe this development is one that only a car wash machine manufacturer deeply familiar with the wash process and on-site needs could have achieved.

In addition to the pure water system, our fourth industry-first innovation is a newly developed coating agent designed to reduce deterioration of plastic components, such as bumpers. These components are particularly vulnerable to deterioration by UV light and our coating, which can be applied after the wash, helps prevent UV exposure.

Daifuku’s car wash machine business will celebrate its 50th anniversary in 2027, the final year of our current four-year business plan. Building on five decades of expertise in car wash technology, we remain committed to developing and delivering not only machines with powerful cleaning performance, but also products and services that drivers can use with confidence and peace of mind.

Shinji Kanamaru

Manager, Standard Design team, Design Department

Auto Wash Division

Daifuku Co., Ltd.