Cleanroom Production Line Systems

Daifuku provides storage and transport systems for clean rooms in semiconductor and flat-panel display (FPD) factories. Semiconductors and FPDs must be manufactured in highly controlled environments that make the handling of items especially challenging. Equipment in the eFA field must be both technically capable and able to accommodate customer requirements to expand their plants to substantial scale, shorten delivery times, and cover an ever-widening delivery area.

Seiji Sato

Director and Managing Officer, e-Factory Automation

Business and value: Providing advanced factory automation for clean rooms

Dust is detrimental to semiconductor wafers, and maintaining dust-free environments is becoming even more important as the miniaturization of integrated circuit (IC) chips proceeds. It takes more than 1,000 processes to make a semiconductor, and any disruption in the flow of the production line can significantly compromise a product’s commercial value, with the damage to just one transport container of products reaching up to hundreds of millions of yen. In addition, the latest and largest 10.5G panels are made from large glass substrates reaching about three meters square but a mere 0.7 millimeter thick. Factories are expanding to massive scale to handle the increasingly large materials and undergo progressively complex processes. At the same time, as technology innovation is fast and furious, delivery lead times for new products must be as short as six months. Daifuku applies its robust technical capabilities to overcome these challenges and has captured the top share of the global market.

Driving growth: Effectively meeting the sharp rise in orders

In fiscal 2017, orders and sales from the electronics industry, primarily in the semiconductor and FPD sectors, grew by roughly 50% over the previous fiscal year. During the period, we installed the first 10.5G TV panel production line system. Sales also grew significantly for organic EL display (OLED) production line systems. Meanwhile, the rapidly expanding IoT market is fueling what is called a super cycle in demand for semiconductors. In addition, the Chinese government has adopted a national policy to ramp up domestic semiconductor production, following South Korea, Taiwan, and the United States. The construction of FPD factories is currently largely concentrated in China.

Our global production structure, including the core factory in Japan and plants in South Korea, China, and Taiwan, has been able to steadily translate the growth in orders during the fiscal year into sales and profits. We will continue developing this structure to meet the brisk demand for cleanroom production line systems, which we expect to continue to be strong into the foreseeable future. We are fully aware that high volatility is a hallmark of our main customer industries, and we will seek to remain flexible and maintain our high product quality to further enhance our high profitability.

Featured Product

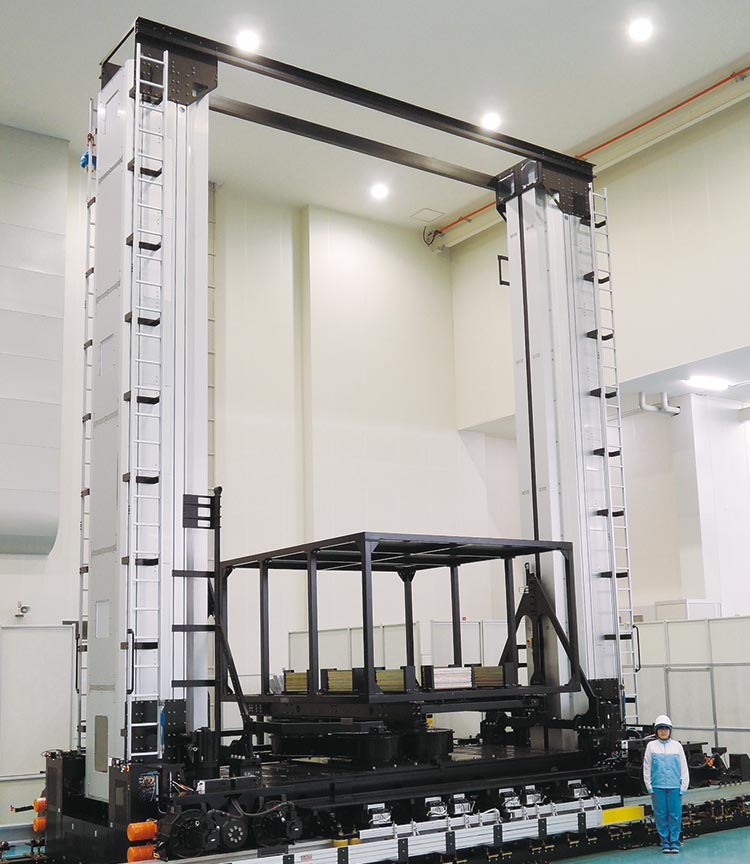

“Clean Stocker” system for FPD production lines

This system for transporting and storing FPD cassettes features highly refined technology capable of handling large and fragile glass substrates—10.5G panels are roughly three meters square and less than one millimeter thick.