Automobile Production Line Systems

Centered on Japanese companies, Daifuku provides automakers with systems for automobile production lines worldwide, including the U.S., China, South Korea, Thailand, and countries in Latin America and Europe. The systems convey car bodies through the entire manufacturing process, including press, weld, paint, and assembly.

Hidenori Iwamoto

Director and Managing Officer, Automotive Factory Automation

Business and value: Supporting the world’s automobile industry over many years

Over the last 60 years, Daifuku has provided automakers worldwide with automobile production line systems. When taking on an extensive upgrade project for a production system with a short completion deadline, even in the most challenging cases, the culture at Daifuku is to “follow through no matter what.” It is through this culture that we earn our customers’ trust and their long-term repeated orders. In addition, after sales service, including upgrades of existing facilities and maintenance, is also a vital component of this business and the weight placed upon it has risen.

Driving growth: A once in a century reform

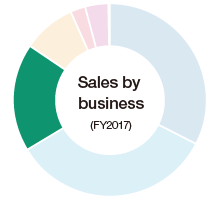

Fiscal 2017 was strong mainly due to new automobile factory construction and large-scale upgrade projects of existing facilities. After-sales service business also noted healthy growth, contributing more than 40% of sales. Moving forward, we will enhance our servicing sites to work in close contact with customers and fully satisfy their needs.

The automobile industry is said to be facing a time of significant change. Manufacturing and sales practices of the past are approaching a true turning point as enhanced safety, self-driving capability, eco-friendliness and electric vehicles, and the shift from vehicle ownership to ride-sharing are among the wide-ranging challenges our customers face. The impact such changes will have on automobile manufacturing will give rise to business opportunities to provide diverse and labor-saving systems for production, and process planning and engineering. There will also be greater opportunities to propose the installation of parts logistics systems within automobile related facilities.

Featured Product

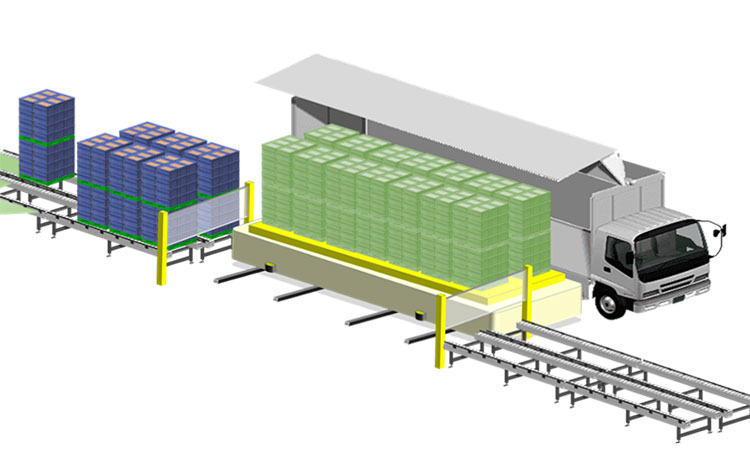

“TRTS” (pronounced “tortoise”) drive-through truck station

At the shipping yard of a parts factory and receiving dock for completed vehicles at automobile factories, the TRTS loads and unloads one full truck load of goods on pallets in a single operation. This reduces forklift operations, with safety improved and loading/unloading time reduced.