This page is for India only.

Customers

Daifuku Intralogistics India, brings a wealth of experience in serving various industries, including Paints, Chemicals, F&B, Tyres, e-commerce, manufacturing & logistics. Our customers range from owner-driven to multinational brands, and our expertise is streamlining operations efficiently. With our deep understanding of compact storage solutions transforming warehousing efficiency by optimizing space, reducing operational costs, and ensuring faster throughput while balancing scalability for diverse industries. Our partners herald from a diverse range of industries, each with a single goal to provide world-class service and delivery to their customers. We help companies throughout India achieve just that.

"Made in India, for India: Our Factory”

Our state-of-the-art factory in Hyderabad spans over 1,437,480 sq. ft., with a dedicated building area of 365,348 sq. ft. Designed to support large-scale operations, it features a full-scale high-bay SRM test facility onsite. Conveniently located just 45 minutes from Hyderabad International Airport, the site is optimized for both innovation and accessibility.

Our meticulously crafted solutions, from industry-leading ASRS systems to always-available spare parts, unlock a whole new level of performance for your warehouse. We're not just an ASRS provider but your strategic partner in building the future of warehousing, leveraging our world-class expertise. Our cutting-edge Hyderabad factory delivers faster lead times, exceptional value, and high-performance intralogistics solutions—including pallet & bin ASRS systems, sorters, and conveyors.

Our integrated Demo Centre in Hyderabad is the only one of its kind in India. It allows businesses to experience Daifuku's automation technologies firsthand and understand how ASRS can optimise their operations and ROI.

The Demo Centre is open to all manufacturers, logistics providers, and supply chain professionals exploring automation. It's a hands-on learning space to see innovation in action.

Solutions

At Daifuku Intralogistics India, we're revolutionising material handling with cutting-edge Japanese technology—made in India, for India. Since 2014, we've been delivering world-class automation solutions tailored to the unique demands of Indian industries. With major sites in Hyderabad and Mumbai, and backed by the global strength of the Daifuku Group, we lead the market in pallet-based ASRS systems, with over 300 installations nationwide for top brands.

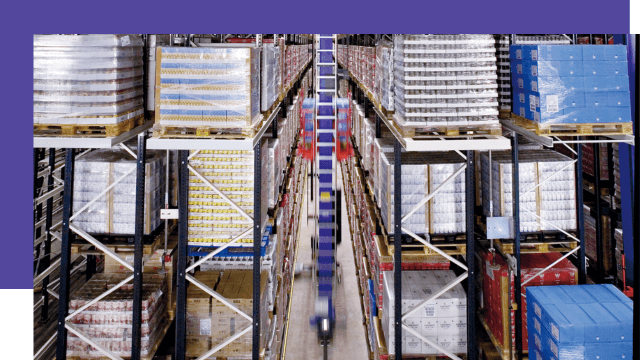

Renowned for high-density pallet storage, rapid operation, and adaptability, Daifuku’s Unit Load Automated Storage and Retrieval System (ASRS) is one of the world's top-selling solutions. Its versatile design, capable of spanning up to 40 meters, allows for seamless customization to fit your specific installation environment and operational requirements. Enhance your storage efficiency with Daifuku’s AS/RS, engineered for superior performance and reliability.

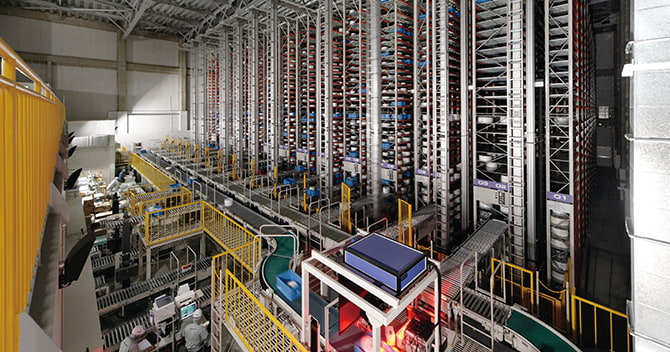

Daifuku Mini Load ASRS provides fast, efficient storage and retrieval for containers or cases of smaller items. Its high-speed operation ensures a ready inventory supply for both order-picking and manufacturing operations. The Mini Load is easy to use and can be easily integrated into your material flow pipeline for efficient operations.

The Mini Load ASRS is designed for industries focusing on speed and space optimization. It is perfect for handling loads like bins, trays, cartons, and other lightweight materials. It suits industries like pharmaceuticals, electronics, e-commerce, and spare parts distribution.

STVs are advanced vehicle-based automation solutions designed to sort and transport materials. They are ideal for scalable operations like retail, logistics, and food distribution. The navigation system allows users to move seamlessly within the warehouse, and sorting capabilities help ensure efficient sorting.

Daifuku's STVs is an advanced pallet sorting system using rail-guided vehicles for efficient material handling. Designed to integrate with Automated Storage and Retrieval Systems (ASRS), the STV enhances warehouse efficiency by streamlining sorting tasks, including transferring goods between automated aisles, order picking stations, and sorting by shipping directions. A specialised freezer model is available for cold chain automation, meeting the demands of cold storage.

Daifuku’s Surfing Sorter is a high speed, positive divert sorter designed to accurately track and gently sort all types of carton sizes and configurations at designated points along the transportation line with a highly reliable sort rate. A wide range of cartons, bins and materials are easily and conveniently transported to their assigned zones at high sortation speeds. Along with various peripheral conveyors and automation equipment to derive full advantage of the sorter capacity, Daifuku provides fast and reliable sortation solution for your logistics needs.

Case Study

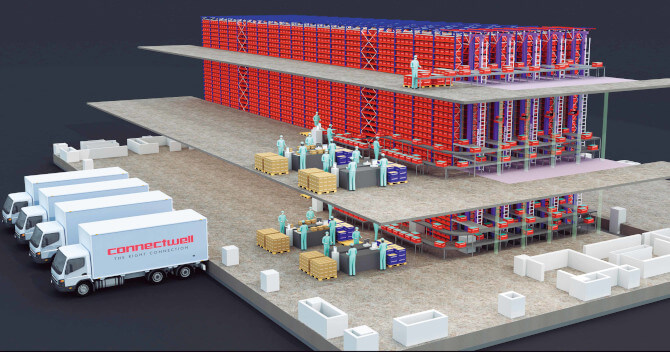

Connectwell Industries

Streamlining WIP and finished goods handling through an automated warehouse

Mahindra & Mahindra

Supporting India’s automotive manufacturing sector with an automated material handling system

S. Narendrakumar & Co. - Everest Spices

Material handling made simple with an AS/RS in India’s food manufacturing industry

Blogs

Visit our Solution Pages

Contact Us

Email: daifuku_solutions@daifuku.co.in

Mobile: +91 7337320275