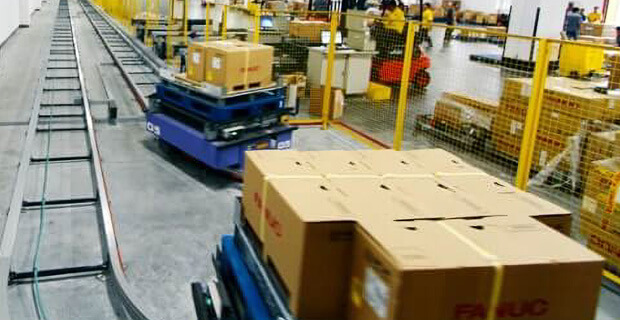

Intralogistics

Learn more about Daifuku's innovative material handling systems and products, including AS/RSs, AGVs, conveyors, picking, and sorting systems.

View the listIntralogistics Products

Customer Service

Cleanroom

Daifuku helps the world's premier semiconductor and liquid crystal panel manufacturers rationalize their production efforts.

Car Wash Machines

Drawing on over 40 years of experience in manufacturing car wash machines, Daifuku's series of environmentally friendly car wash solutions save water and minimize noise.

Columbarium

Daifuku's automated warehouse technology solves the problem of grave shortages in urban areas.

Wireless Power Supply Solutions

Get more information on the battery-charging and wireless charging systems that are gaining interest in the industrial arena.

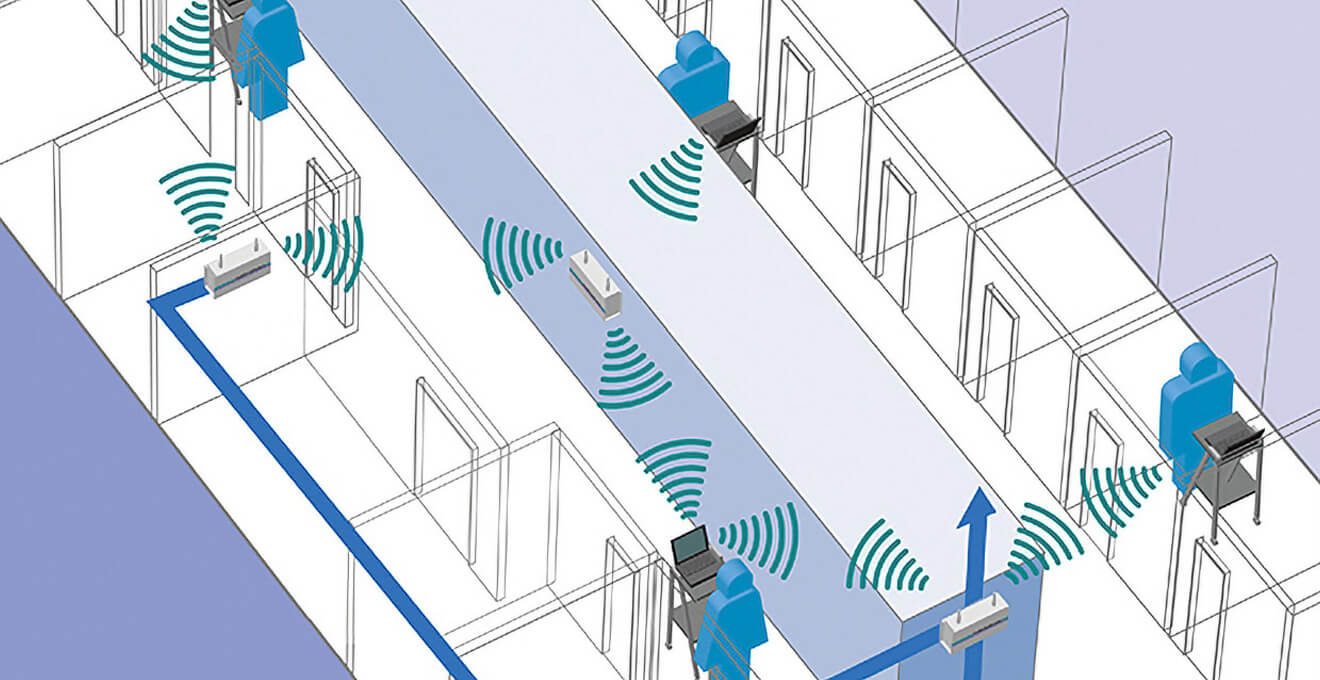

RFID Solutions (Singapore)

Daifuku Singapore has conducted extensive proof-of-concepts on the RFID technology and designed a comprehensive workable solution in the most challenging environment for many of our customers.

Case Studies

Mahindra & Mahindra

Painted vehicle body storage and sequencing AS/RS system

S. Narendrakumar & Co. - Everest Spices

Material Handling Made Simple' at Everest Spices with DAIFUKU AS/RS

Coca-Cola Bottlers Japan Inc.

Distribution and sales network optimization through advanced end-to-end automation

Contact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact UsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact Us