Automotive

At the Daifuku Group, we have close to a century-long proven track record in automobile production line systems. We supply automated systems for the entire manufacturing process—from pressing, welding, painting, assembly, parts storage and supply, through to engine testing. Motorization is expanding on a global scale, including a worldwide increase in eco-friendly cars and locally-oriented models. We support this expansion with our cutting-edge logistics technologies and automobile production solutions.

An Introduction to Daifuku’s automotive business

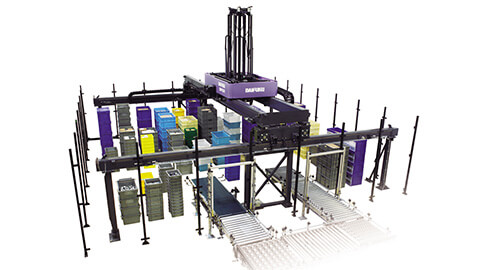

Product Lineup

Applications

Case Studies

Honda Motor Co., Ltd.

Reducing energy consumption and contributing to the mass production of electric vehicles through cutting-edge technology and efficient production structure

Dongfeng Honda Automobile Co., Ltd.

State-of-the-art plant expands production capacity, driving advanced manufacturing and environmental friendliness

Mahindra & Mahindra

Painted vehicle body storage and sequencing AS/RS system

PT Mitra Pinasthika Mulia

Intralogistics solution cut the lead time by a third

Enabling same-day shipment of orders

Piolax Corporation

Leading manufacturer of automotive parts sees substantial improvements with installation of automated warehouse

Contact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact UsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact Us