Baggage Handling Systems

Daifuku Airport Technologies is a leading global provider of end-to-end baggage handling solutions, offering an unparalleled network of expertise and support from project conception through to system maintenance. More than 500 airports around the world depend on our leading-edge technology to engineer, manufacture, install, and service Baggage Handling Systems. Daifuku enhances the productivity, accuracy, and passenger service levels of our partners while creating a seamless airport journey for their passengers.

Products

CHECK-IN CONVEYORS

Daifuku's check-in conveyors are designed to increase efficiency, minimize maintenance, and improve overall service at ticketing counters

SECURITY SCREENING

Our security screening solutions facilitate the efficient sortation of passenger baggage while maintaining high levels of security.

Mobile Inspection Tables (MITs) are an innovative solution, designed for use inside airport checked baggage reconciliation areas (CBRA). Implemented as a replacement for traditional belt conveyors and static search tables, the MIT utilizes leading-edge robotic technology to bring a range of operational benefits to CBRAs. The stainless steel MIT top matches the dimensions of traditional search tables and meets all PGDS 7.0 requirements.

CONVEYORS AND CAROUSELS

We provide a dynamic range of conveyor and baggage carousel solutions to meet the demands of all airport terminal environments. As one of the few providers that make all three types of baggage carousels, we provide flexible alternatives to accommodate the various demands of your baggage handling system.

General Transport Conveyors are designed to transport in a straight line and can be programmed to provide a variety of functions such as merging, accumulating, inducting, and sorting baggage.

Merge Conveyors are highly functional in design, featuring an angled edge (30o or 45o) where two convey lines meet. This allows merging baggage to move from one conveyor line to another at either low or high speed.

Collector Conveyors perform the specific function of collecting baggage at the check-in area. Bags can be loaded directly onto the conveyor by the check-in operator or, if used with check-in conveyors, bags can be injected automatically.

Metering Conveyors are short straight conveyors used for metering or queuing bags, or they can be used for creating bag separation. These conveyors are designed with robust components to cope with a high number of stops/starts.

Crescent Pallet Carousels re-circulate baggage through a series of crescent-shaped pallets, linked together to form a continuous loop; they can be used as either arrivals carousels or baggage hall make-up carousels.

Overlapping Slat Carousels re-circulate baggage through a series of rectangular-shaped slats, overlapped and linked to form a continuous loop; it can be used as either arrivals carousels or baggage hall make-up carousels.

Incline Claim Carousels re-circulate baggage continuously and can be used as arrival carousels or make-up loops. They are traditionally used in international travel halls when there is a need for a higher accumulation of bags.

EARLY BAGGAGE STORAGE

Our Early Bag Storage System (EDB) system is primarily used to store and release bags that have been delivered to the airport early. We offer a range of advanced technologies in addition to standard conveyor-based EBS, including Baggage Tray System (BTS) lane-based storage and high-speed Automated Storage and Retrieval Systems (ASRS).

SORTATION SOLUTIONS

Daifuku is a leading global provider of efficient, high-speed solutions for the transportation and sortation of passenger bags from check-in counters to baggage make-up areas. Our dynamic solutions are among the world’s fastest.

Tilt Tray Sorters are a typical component of the larger Baggage Handling System (BHS), tasked with controlling and discharging bags for a variety of applications, such as pre-sortation, final sortation to make up locations, early bag storage, and screening applications within the overall BHS.

Baggage Tray Systems (BTS) transport bags in individual trays that are equipped with identifiable RFID tags. This allows 100% tracking and traceability of baggage throughout the BHS, dramatically reducing operational issues caused by low tracking performance.

Vertical Sorting Units can divide the tray flow into two vertically separated paths, based on the individual tray or route selection.

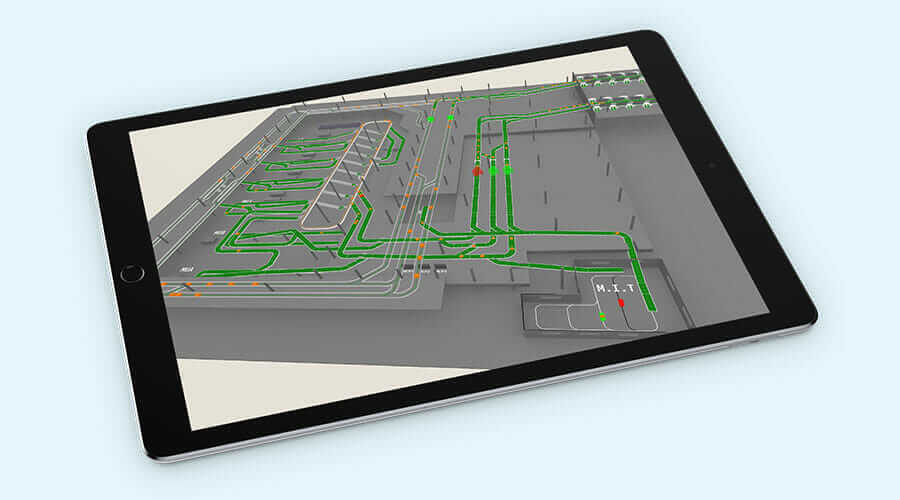

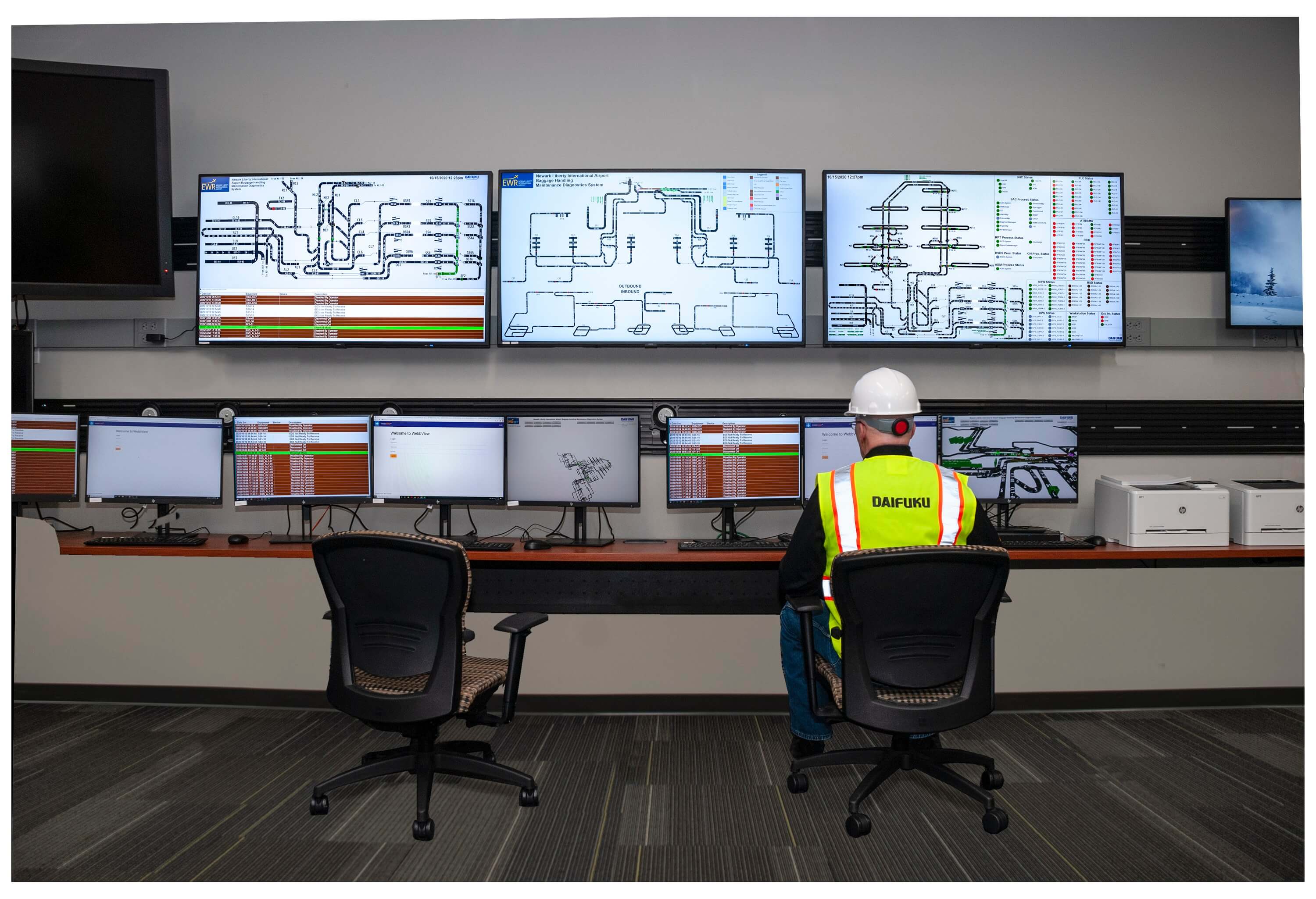

SIMULATION, EMULATION, AND SCADA

Daifuku’s industry-leading software solutions incorporate a range of operational applications for our airport and airline partners. The entire suite of solutions features integrated redundancy architecture, providing unparalleled system resilience for day-to-day operations.

CONTROL SYSTEMS

At Daifuku, we push the boundaries of what is possible, with a focus on creating solutions that enhance the lives of airport passengers and our customers. With flexible sortation engines that can facilitate the delivery of baggage, our software is proven to function on conventional conveyors, tilt tray sorters (TTS), baggage tray sorters (BTS), and hybrid sortation systems with ease.

Airflow is Daifuku’s Baggage Handling System (BHS) management suite and includes all modules necessary to manage both simple and complex BHS solutions in full compliance with IATA 753.

WebbView® is the most advanced integrated baggage handling control system (BHS). This comprehensive solution optimizes baggage throughput and tracking accuracy while minimizing system downtime.

Contact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact UsContact Us

For product inquiries, please reach out to us via our Contact Us page.

Contact Us