Production Line Optimization Solutions

Daifuku’s tailored proposals are based on a wealth of experience and

proven technology supporting the automotive industry.

Let Daifuku support your drive for greater productivity.

Daifuku can help with

production line automation

even for companies

without a dedicated planning and design team.

-

Consulting

-

Engineering

-

Equipment procurement, construction, adjustment

Full turnkey support,

from factory planning and initial analysis

to automation equipment installation

- Daifuku

Factory Planning Consulting

- Daifuku’s services include feasibility studies (FS) for new factory constructions, simultaneous product engineering (product SE; designing with input from production preparation and manufacturing departments), and value analysis/value engineering (VA/VE; reducing costs and improving quality from the design stage). Our proposals are designed to lay the groundwork for new processes essential for manufacturing in any field, including not only automobiles but also agricultural machinery, construction equipment, home appliances, and housing.

- Daifuku

Factory Planning Consulting

-

- • Site surveys and analysis

- • Concept creation support

- • Investment planning

- • Planning input from automobile production specialists

- • Visualization of current production statuses

- • Logistics system plan optimization

- Daifuku

Process Planning

Engineering

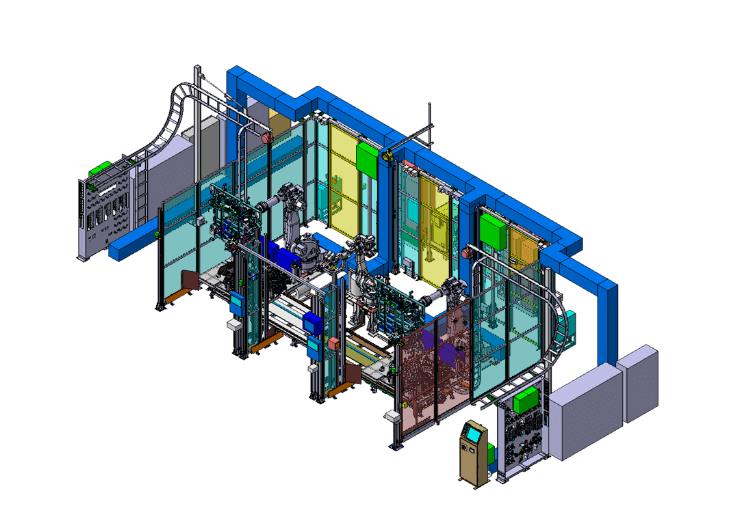

- With consideration for overall production balance, Daifuku offers extensive process-specific services including creating layouts, recommending equipment specifications, creating design drawings, selecting equipment, and managing the processes themselves. Daifuku uses 3D simulation tools to perform preliminary verifications and evaluations for improving design accuracy, ensuring products can be completed as quickly as possible. Daifuku also helps keep investment costs low by proposing only the equipment that meets the necessary functions.

-

- Automation analysis in automobile body transfer process

-

- Automation analysis in door removal process

- Daifuku Automation Equipment

Procurement, Construction, and Adjustment

- Daifuku performs on-site installation and adjustment in addition to automation equipment procurement and manufacturing. Through digitalization and off-line robot programming, Daifuku can help minimize the time spent on-site during factory startup. Daifuku has extensive experience not only in large-scale site updates but also in getting sites up and running as quickly as possible.

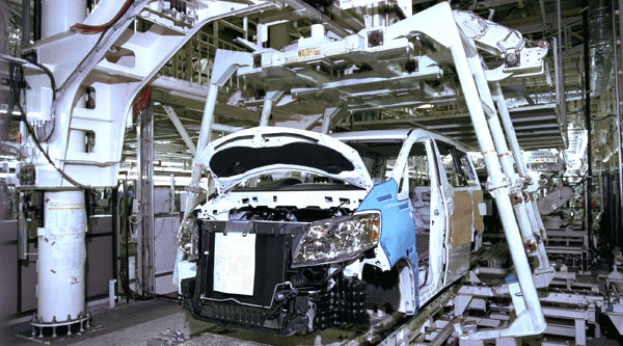

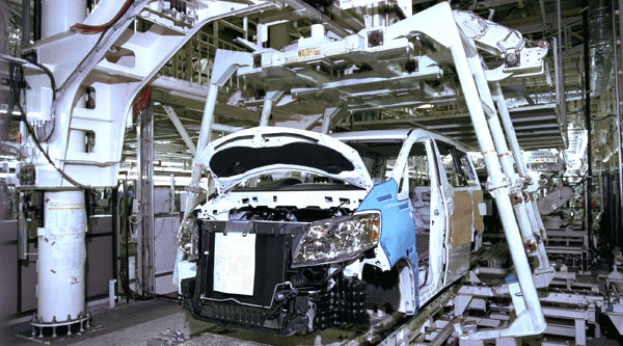

- Automobile production line systems

- Agricultural machinery production line systems

Proposal Examples

Automatic

nut-tightening equipment

for assembly processes

• Detailed production designing

• General production activities

• Mechanical, electrical, and adjustment work

Plastic molded product assembly processes

for new automobiles

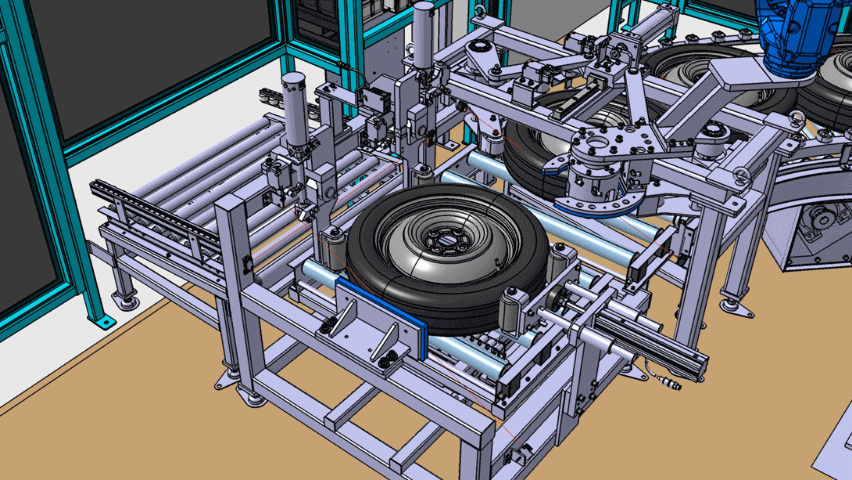

Spare tire mounting equipment

Working Together

Toward Success

Daifuku’s Automotive Division provides a wide range of services for the automotive industry and various other fields —from general production preparation to engineering services for optimizing production lines.

POINT 1Consulting with an eye

toward the future

POINT 2Solving problems

using PDCA/OODA

POINT 3Optimizing proposals with LPS

(Lean Production Systems)

Contact

For inquiries about Daifuku’s production line

optimization support services