Featured

Daifuku in India

Solutions

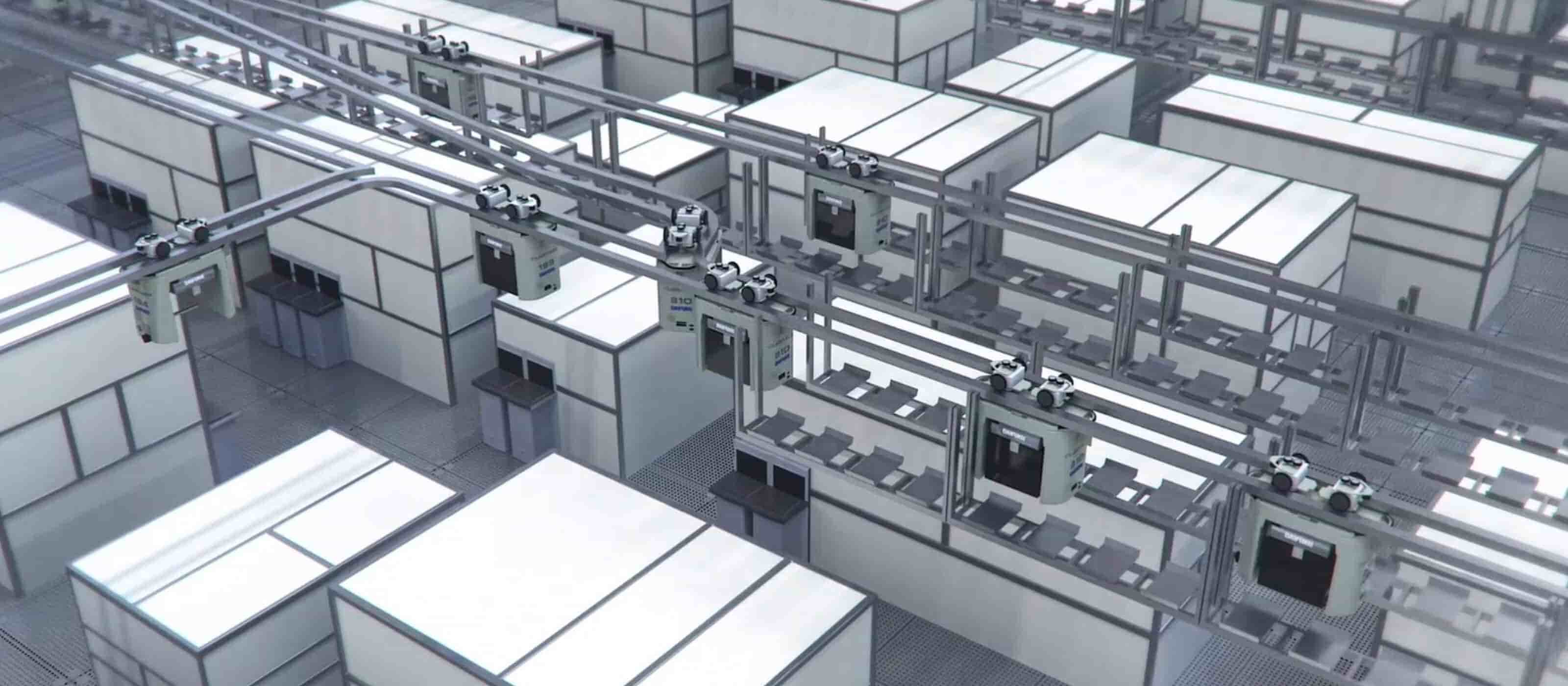

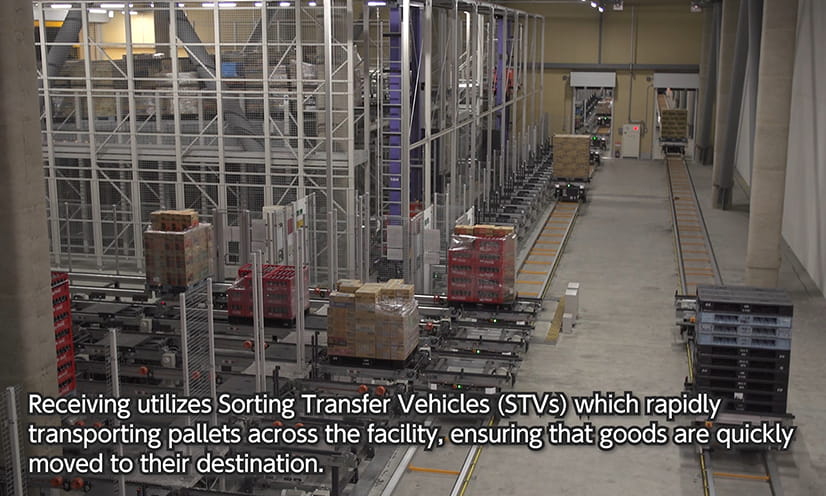

Intralogistics

Learn more about Daifuku's innovative material handling systems and products, including AS/RSs, AGVs, picking, and sorting solutions.

Cleanroom Site

Promotion website to introduce Daifuku’s Storage/Conveyor Systems for Cleanrooms, mainly with videos.

Airport Technologies

Discover how Daifuku Airport Technologies can support your business and passengers.

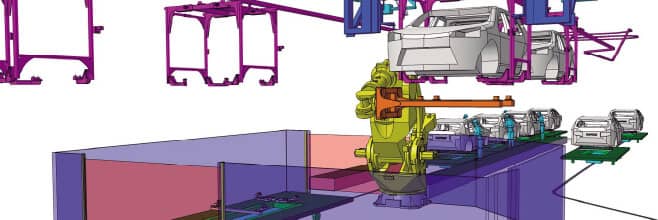

Production Line Optimization Solutions

Daifuku offers extensive process-specific services in production preparation for new factory constructions or production line updates.

Columbarium

Daifuku's automated warehouse technology solves the problem of grave shortages in urban areas.